Synthesis method of high-purity AlSiC flaky powder

A flake powder and AlSiC technology, which is applied in the synthesis of high-purity AlSiC flake powder, can solve the problems of high raw material cost, impossibility of large-scale industrial application, and high price of AlSiC, so as to improve strength, The effect of high purity and strengthening structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

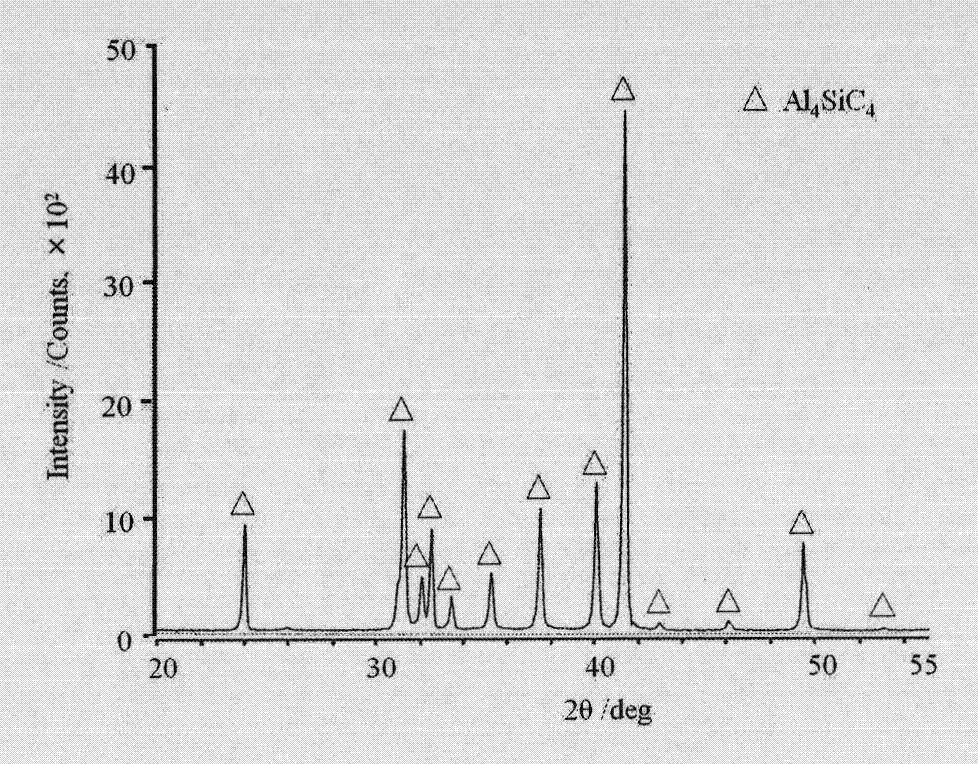

[0023] Embodiment 1, preparation of aluminum silicon carbon flake powder

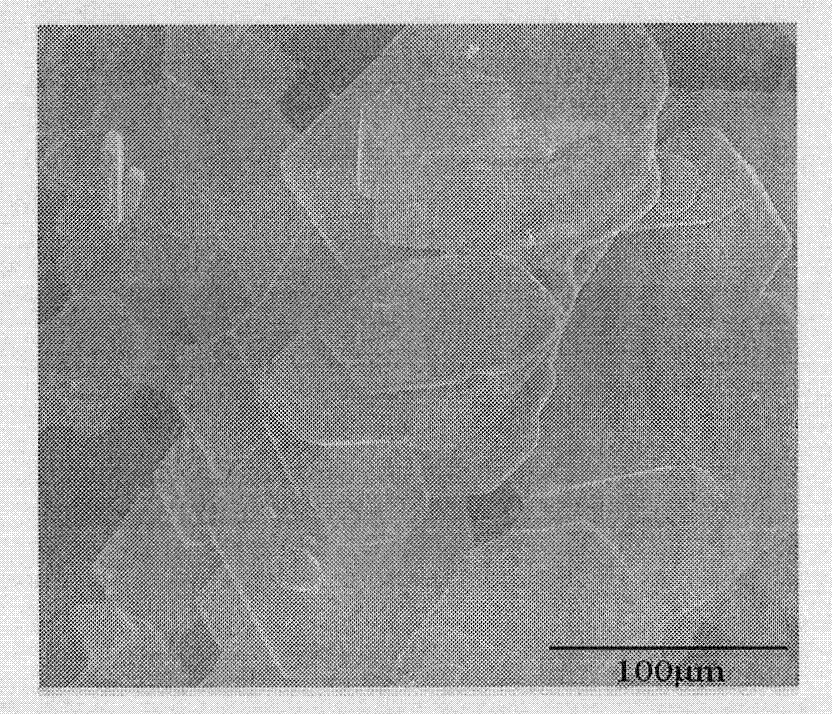

[0024] The selected formula is: Al 2 o 3 Fine powder (average particle size 0.01mm): quartz sand (average particle size 0.01mm): carbon black (average particle size 0.01mm): black SiC (average particle size 0.1mm) = 54:15:30:1 (mass ratio), weigh Measure the ingredients and dry mix them in a ball mill to obtain a mixture. Put the mixture into a graphite crucible, put the graphite crucible into an electric furnace, and heat at 1900°C in a protective atmosphere with a CO partial pressure of 0.5 and an Ar gas partial pressure of 0.5 (the total pressure of the protective gas is 1 atmosphere, and the flow rate is 1L / min). Keeping the temperature for 2 hours, after cooling, remove the impurity-enriched layer on the upper surface to obtain a flaky Al-SiC powder with a length and width of 50-200 μm and a thickness of 4-5 μm. Al in the obtained flake AlSiC powder 4 SiC 4 The content is 99.2%. The scanning ...

Embodiment 2

[0026] Embodiment 2, preparation of aluminum silicon carbon flake powder

[0027] The selected formula is: fused corundum (average particle size 0.5mm): quartz sand (average particle size 0.5mm): graphite (average particle size 0.1mm): green SiC (particle size about 0.5mm) = 55:13:28:4 (mass ratio ), weigh the ingredients, and dry stir evenly to obtain the mixture. Put the mixture into a graphite crucible, put the graphite crucible into an electric furnace, and heat at 2000°C in a protective atmosphere with a CO partial pressure of 0.60 and an Ar gas partial pressure of 0.40 (the total pressure of the protective gas is 1 atmosphere, and the flow rate is 1l / min). Insulate for 5 hours, after cooling, remove the impurity-enriched layer on the upper surface to obtain a flake-shaped aluminum-silicon carbon powder with a length and width of 50-200 μm and a thickness of 4-5 μm. 4 SiC 4 The content is 99.1%.

Embodiment 3

[0028] Embodiment 3, preparation aluminum silicon carbon flake powder

[0029] The selected formula is: sintered corundum (average particle size 0.8mm): quartz sand (average particle size 0.8mm): petroleum coke (average particle size 0.8mm): black SiC (average particle size 0.8mm) = 47:11:40:2 (mass ratio ), weigh the ingredients, and dry mix them in a ball mill to obtain a mixture. Put the mixture into a graphite crucible, put the graphite crucible into an electric furnace, and heat at 2200°C in a protective atmosphere with a partial pressure of CO of 0.9 and a partial pressure of Ar gas of 0.1 (the total pressure of the protective gas is 1 atmosphere, and the flow rate is 1l / min). Insulate for 5 hours, after cooling, remove the impurity-enriched layer on the upper surface to obtain a flake-shaped aluminum-silicon carbon powder with an average length and width of 180 μm and an average thickness of 5 μm. 4 SiC 4 The content is 99.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com