1200V/50A IGBT power module based on rapid sintering nano-silver soldering paste pressure-free interconnection technology

A rapid sintering and nano-silver technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of automatic production of packaged power semiconductor devices, permanent chip damage, improper pressure selection, etc. problems, achieve excellent thermal cycle fatigue aging resistance, avoid pre-stress damage, reduce contact resistance and thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

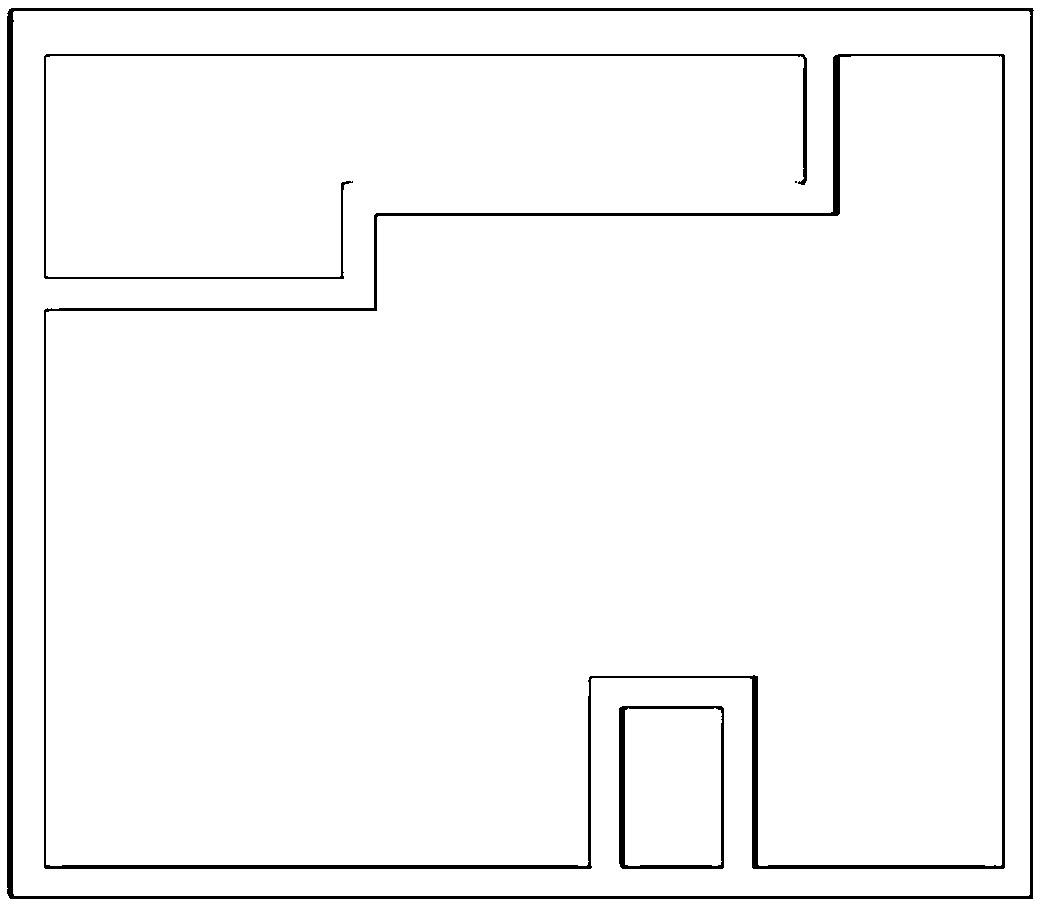

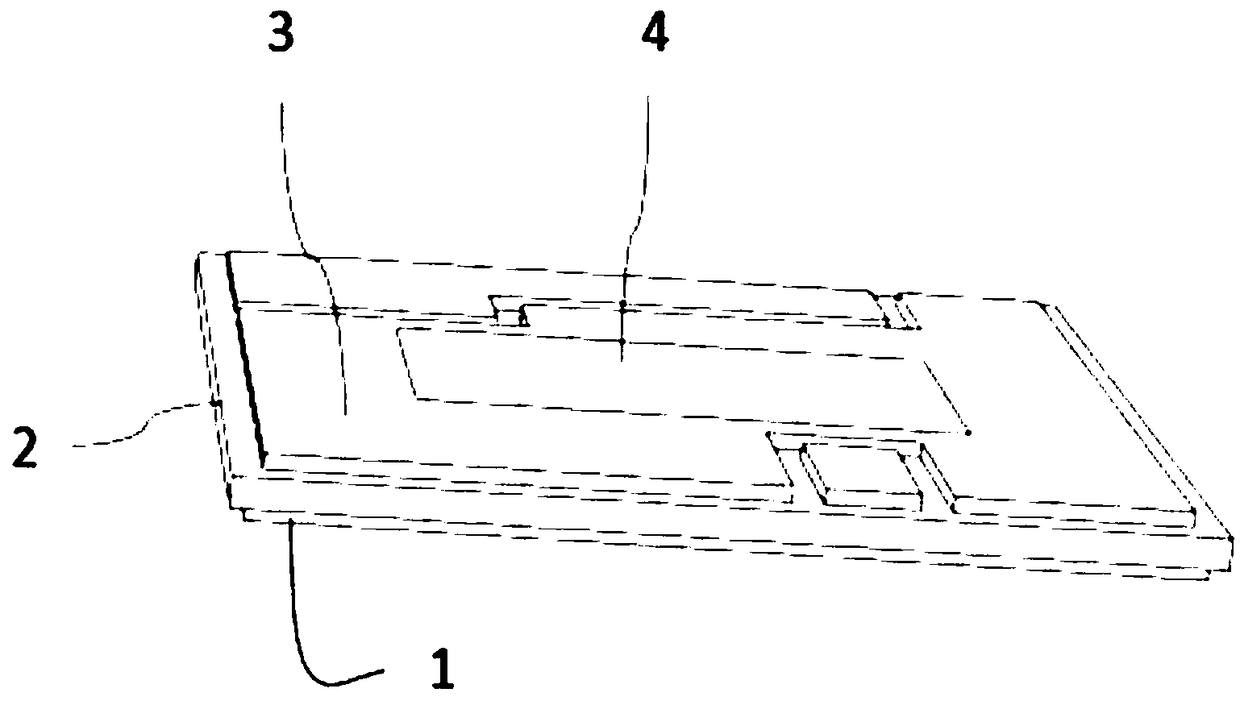

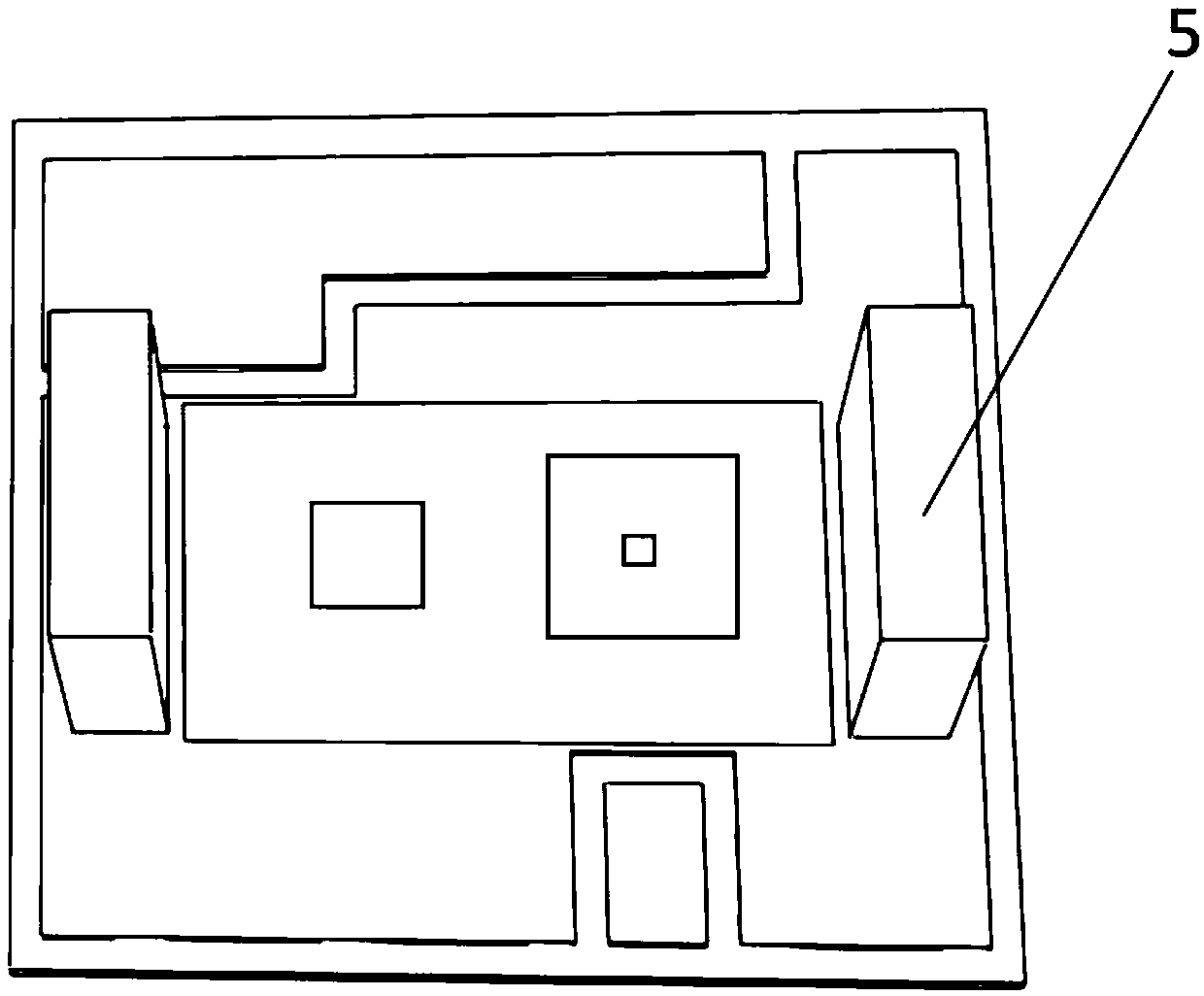

Image

Examples

example 1

[0034] Example 1: Conduct insulation leakage test on 1200V / 50A IGBT power module based on rapid sintering nano-silver solder paste interconnection technology, static I-V characteristic, dynamic switching characteristic test, basically consistent with the leakage curve of commercial modules of the same level, with the same good electrical performance performance.

example 2

[0035] Example 2: Conduct thermal resistance test on a 1200V / 50A IGBT power module based on rapid sintering nano-silver paste interconnection technology. Compared with commercial modules of the same level, the thermal resistance is reduced by 12%, and it has better heat dissipation characteristics. Under certain conditions, the junction temperature of the IGBT module prepared by current rapid sintering of nano-silver solder paste is lower.

example 3

[0036] Example 3: The 1200V / 50A IGBT power module based on the rapid sintering nano silver solder paste interconnection technology was subjected to high and low temperature impact aging and power cycle aging tests. After 500 cycles of aging, the same level of commercial modules failed. The thermal resistance of the IGBT module prepared by current rapid sintering nano-silver solder paste experienced 1000 cycles of high and low temperature aging shock, and its thermal resistance did not increase significantly. The lifespan of commercial modules of the same level fails after 63K cycles, and the lifespan of IGBT modules prepared by current rapid sintering nano-silver solder paste is 80K cycles.

[0037] The present invention is based on the 1200V / 50A IGBT power module of the rapid sintering nano-silver solder paste pressureless interconnection technology. The sintering connection process does not require additional auxiliary pressure, and the current-assisted pressureless sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com