Medium-temperature cured conductive slurry specially used for AlSiC LED support

A conductive paste, medium temperature technology, applied in conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problems of high sintering temperature, high resistivity, poor electrical conductivity, etc., reaching the sintering temperature The effect of low, good conductivity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

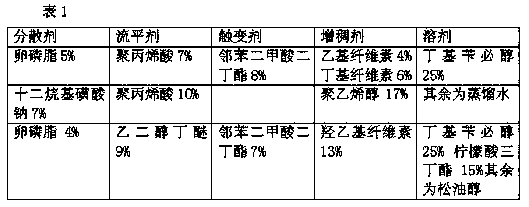

Examples

preparation example Construction

[0032] The preparation method of described silver particle comprises the following steps:

[0033] A. Under stirring, add a complexing agent to the silver nitrate aqueous solution to form a nitrate complex solution, then add a surfactant to the nitrate complex solution, and adjust the pH value between 9-12 , to obtain a homogeneous solution, the total volume concentration of silver nitrate in the homogeneous solution is 10-95g / L;

[0034] B. Increase the stirring speed to above 300rpm, add the reducing agent solution dropwise to the above homogeneous solution, and control the reaction temperature at 25°C;

[0035] C, after the reaction is completed, reduce the stirring speed to below 300rpm, add phosphoric acid in the system that step B obtains, the volume percent concentration of described phosphoric acid is 20%, is used for regulating the pH value in the system, makes the pH value 2- 7; After standing still, the silver paste particles are separated out, then separa...

Embodiment 1

[0039] Under stirring, dissolve 60g of silver nitrate in 2000ml of water, and add 50ml of ethylenediamine to it to form a silver-ammonia complex solution, then add 138g of concentrated ammonia water to adjust the pH value, and dissolve octadecyl carboxylic acid once. After the octadecyl hydroxy acid is completely dissolved, add 400ml of aqueous solution containing 7g of sodium borohydride to it under vigorous stirring. The whole addition process continues for 30 minutes. After the addition is completed, stir and react for 20 minutes. The whole reaction process is maintained at room temperature. Then the stirring speed was reduced, and 200ml of 20% phosphoric acid was slowly added thereto. After the addition, it was left still for 1 h and filtered to obtain a black solid. Wash the black solid twice with 500ml of n-propanol, and then filter to obtain about 27g of "wet" silver particles (silver particles). Fully dissolve the thickener solvent in the solvent, and add dispersant, ...

Embodiment 2

[0041] Under stirring, add ammonia water to the silver nitrate aqueous solution to form a nitrate complex solution, then add C8-C18 fatty acid salt to the nitrate complex solution, and adjust the pH value between 9-12 , to obtain a homogeneous solution, the total volume concentration of silver nitrate in the homogeneous solution is 10-95g / L; increase the stirring speed to more than 300rpm, add ascorbic acid dropwise in the above-mentioned homogeneous solution, and the reaction temperature is controlled at 25°C; After the reaction is completed, reduce the stirring speed to below 300rpm, and then add phosphoric acid to the obtained system, the volume percentage concentration of the phosphoric acid is 20%, which is used to adjust the pH value in the system, so that the pH value is 2-7; Stand still to precipitate the silver paste particles, then separate, wash with an organic solvent, and separate again to obtain silver particles with a particle size of less than 100 ("wet" silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com