Copper-covered ALSiC composite radiating substrate and manufacturing method thereof

A technology of heat dissipation substrates and substrates, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor wettability of metals and ceramics, low reaction ability of metals and ceramics, and high requirements for molding dimensional accuracy, achieving good application prospects , expand practicability, and solve the effect of thermal expansion mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

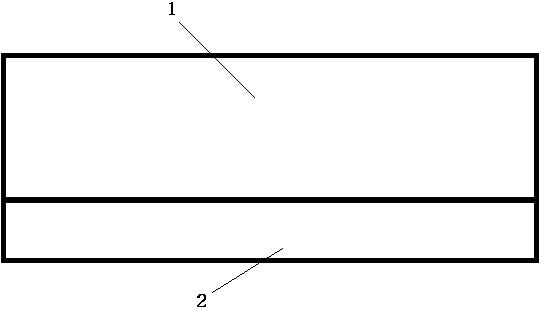

[0028] Such as figure 1 As mentioned above, the copper-clad AlSiC composite heat dissipation substrate of this embodiment includes an AlSiC substrate 1 and a copper layer 2 attached on the AlSiC substrate 1 . A copper-aluminum spinel eutectic interface is formed between the copper layer and the AlSiC substrate.

[0029] Among them, the AlSiC substrate is an Al-based composite material with SiC as a reinforcing phase. The thickness of the AlSiC substrate is 1 mm, and the thickness of the copper layer is 0.3 mm.

[0030] The preparation method of the copper-clad AlSiC composite heat dissipation substrate of this embodiment includes steps (1) to (4) as described below.

[0031] In step (1), polish one side of the unpolished AlSiC substrate to a mirror surface, then clean the soaked AlSiC substrate with absolute ethanol through an ultrasonic cleaner for 10 to 15 minutes, and dry it to remove the adhering Grease and other sundries.

[0032] In step (2), the polished side of the...

Embodiment 2

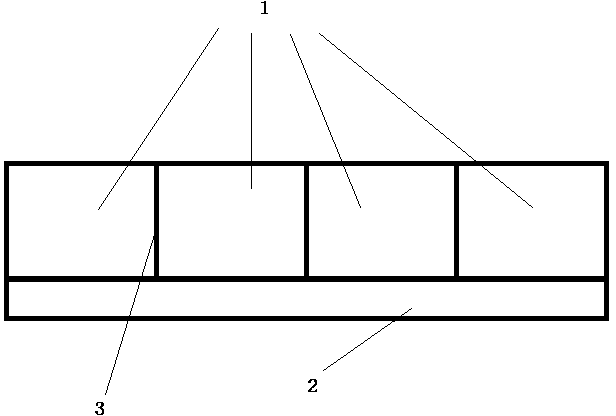

[0036] Such as figure 2 As shown, the copper-clad AlSiC composite heat dissipation substrate of this embodiment includes an AlSiC substrate 1 , a copper layer 2 and a thermally conductive adhesive 3 . Among them, a plurality of AlSiC substrates 1 are assembled into a plate shape and attached to the copper layer 2, and the gaps between adjacent AlSiC substrates 1 are filled with thermally conductive adhesive 3 to enhance the overall strength. A copper-aluminum spinel eutectic interface is formed between the copper layer and the AlSiC substrate.

[0037] Among them, the AlSiC substrate is an Al-based composite material with SiC as a reinforcing phase. The thickness of the AlSiC substrate is 1 mm, and the thickness of the copper layer is 0.5 mm.

[0038] The preparation method of the copper-clad AlSiC composite heat dissipation substrate of this embodiment includes steps (1) to (5) as described below.

[0039] Step (1), polish one surface of the unpolished AlSiC substrate to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com