Light-emitting diode (LED) packaged on basis of AlSiC composite substrate

A composite substrate and LED chip technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of poor wettability of metal and ceramics, low reaction ability of metal and ceramics, and high requirements for molding dimensional accuracy, and achieve good Application prospects, greater specific stiffness, and the effect of solving thermal expansion mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

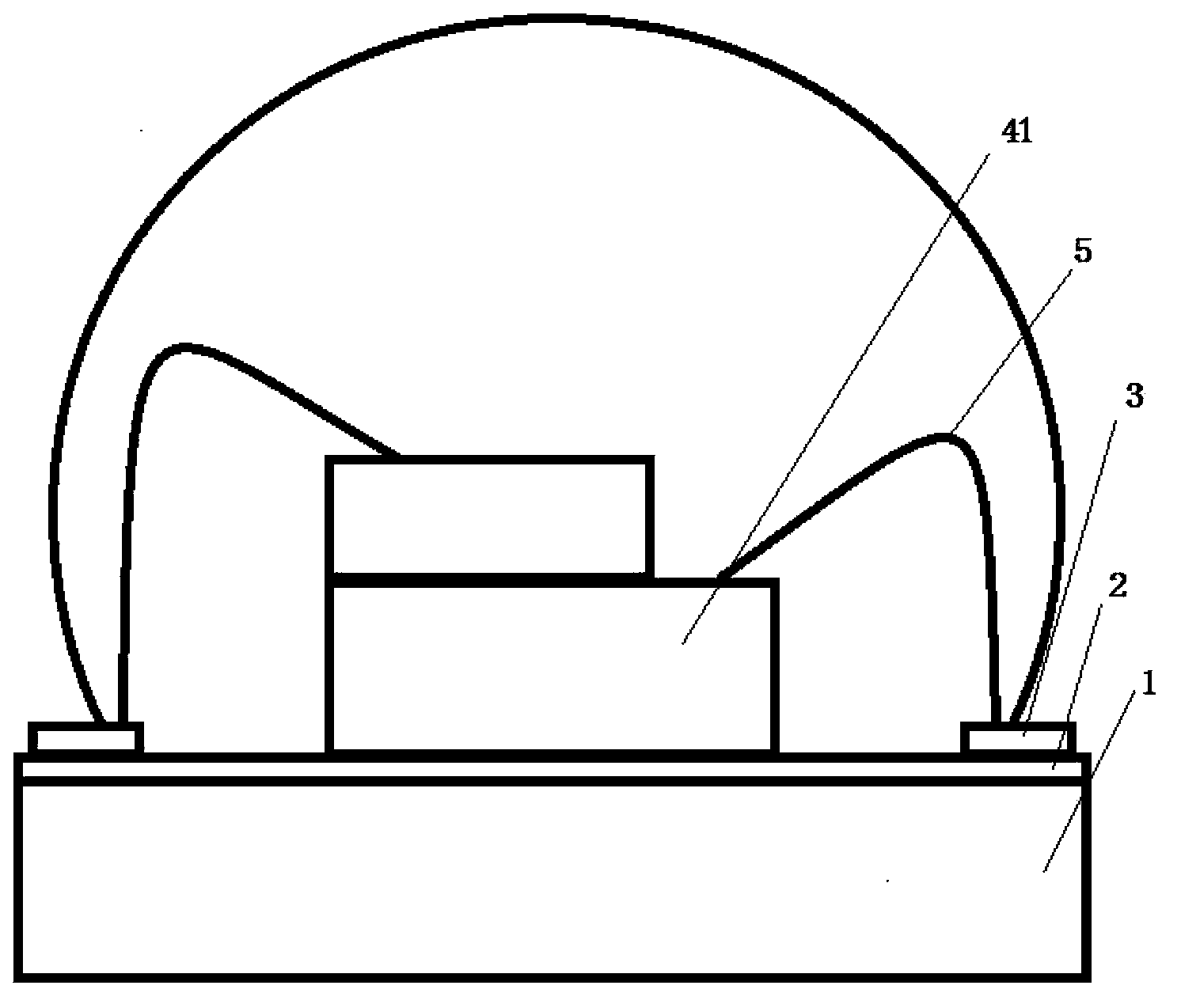

[0019] Such as figure 1 As described, the LED packaged based on the AlSiC composite substrate of this embodiment includes an AlSiC composite heat dissipation substrate 1 plated with an AlN insulating layer 2, two copper film electrodes 3, an LED chip 41, and a gold wire 5.

[0020] The LED chip package is packaged on the AlSiC composite heat dissipation substrate coated with an AlN insulating layer by using a COB (chip on board, COB) packaging process; two copper film electrodes are plated on the AlN insulating layer, and they are connected to each other through gold wires. The positive and negative poles of the LED chip are connected. The thickness of the AlN insulating layer in this embodiment is 2.5 μm, and the LED chip is a single-particle packaged LED chip.

[0021] The manufacturing method of the LED based on the AlSiC composite substrate package of this embodiment is as follows:

[0022] (1) Polish the unpolished AlSiC composite substrate to a mirror surface. After polishing,...

Embodiment 2

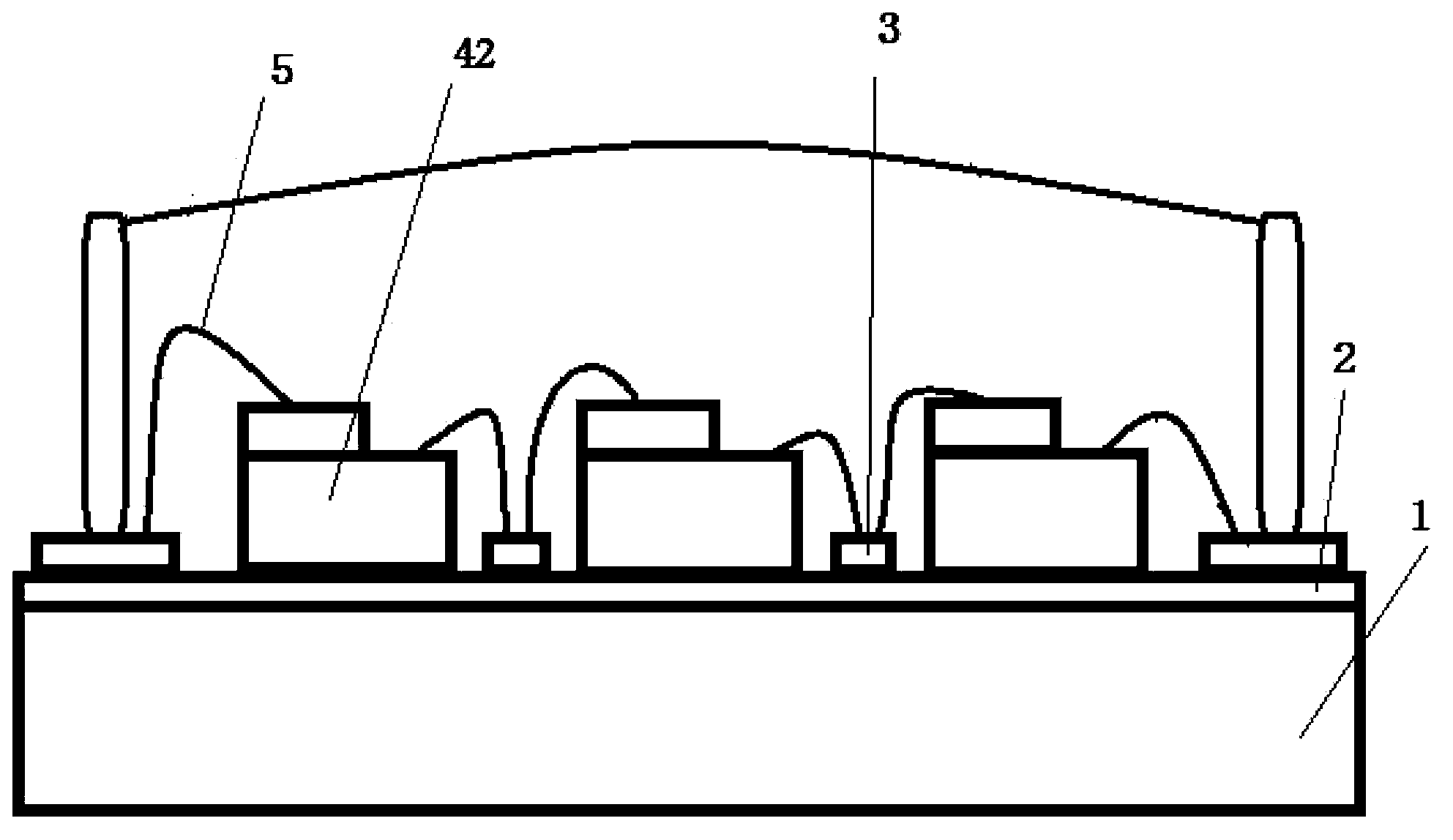

[0028] The LED based on the AlSiC composite substrate package of this embodiment is as figure 2 Shown.

[0029] Except for the following features of this embodiment, the remaining features are the same as in Embodiment 1: The thickness of the AlN insulating layer 2 is 3 μm, and the LED chip is a light source module 42 integrated with a multi-particle chip.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com