Welding method and welding system for angle measuring antenna

A technology of angle measuring antenna and welding method, which is applied to welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effects of effective control of welding heat input, low equipment operating cost, and simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

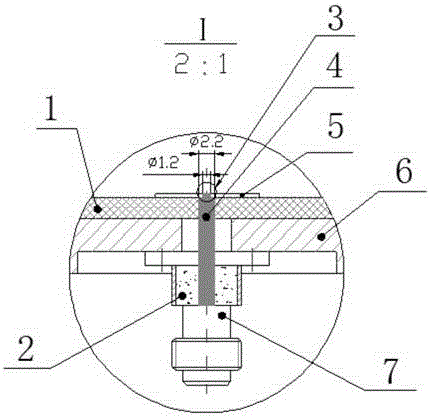

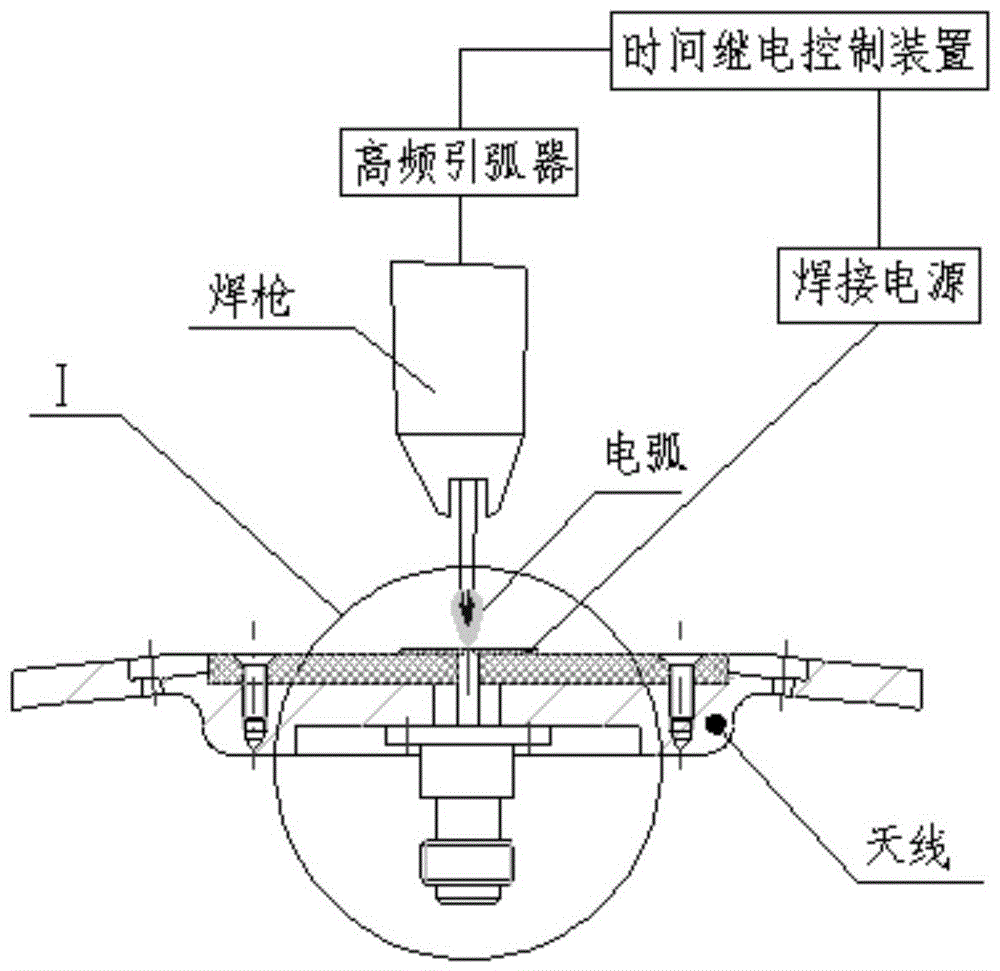

[0014] The invention provides a welding method for a connector kovar alloy microstrip and copper foil on a goniometric antenna, the diameter of the kovar alloy microstrip is φ2.2mm, the diameter of the circular copper foil is φ16mm, and the thickness is 0.5mm . The detailed assembly structure is as figure 1 , figure 2 As shown, the welding system is mainly composed of a welding time relay control device, argon tungsten arc welding welding power supply, welding torch, and argon gas cylinder. The time relay control device is used to accurately control the energized welding time of the argon arc welding power source, and the control accuracy is 0.01s, and then to control the arcing and arcing time of the welding torch, so as to meet the requirements of small welding spots w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com