Butt welding method for T23 steel tube and G102 steel tube

A steel pipe and butt welding technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of decreased toughness of welded joints and unguaranteed welding quality, and achieves increased welding speed, improved welding quality, and reasonable welding heat input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

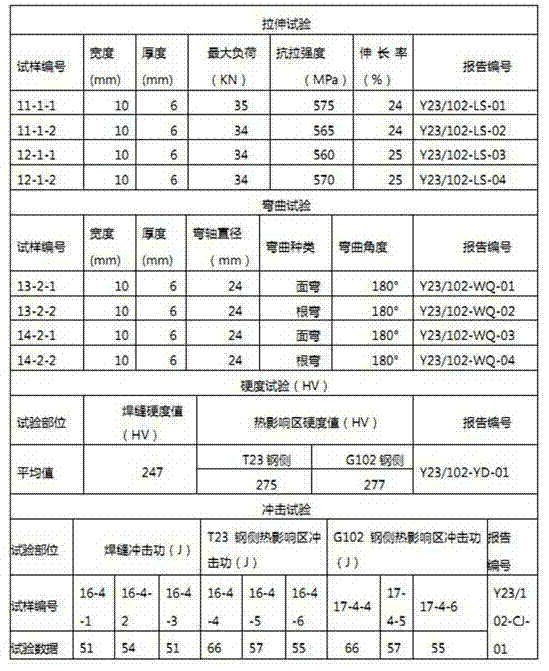

Examples

Embodiment Construction

[0018] To sum up, the present invention discloses a butt welding method of T23 steel pipe and G102 steel pipe, comprising the following steps:

[0019] The first step is to bevel the end of the steel pipe;

[0020] The second step is to assemble the steel pipes to be butt-welded. The ends of the two steel pipes of the pair are in contact, placed horizontally, and the axes of the two steel pipes coincide;

[0021] The third step is to use pulse tungsten argon arc welding to weld the steel pipe.

[0022] The third step includes root layer welding and surface layer welding, and the filling duty ratios formed by root layer welding and surface layer welding are respectively 50%.

[0023] The welding current of the root layer welding step is 70 / 110A, wherein 70A is the base value current, 110A is the peak current, the voltage used is 11V, the pulse frequency of pulse tungsten argon arc welding is 1.5Hz, and the welding speed is 2.9 -3 cm / min.

[0024] The root layer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com