A composite heat-generating friction stir welding tool

A friction stir welding and welding machine technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as large time delay and overshoot, large device size, and no solution is provided, and achieve control welding. Effects of heat input, improved welding efficiency, and shortened preheating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

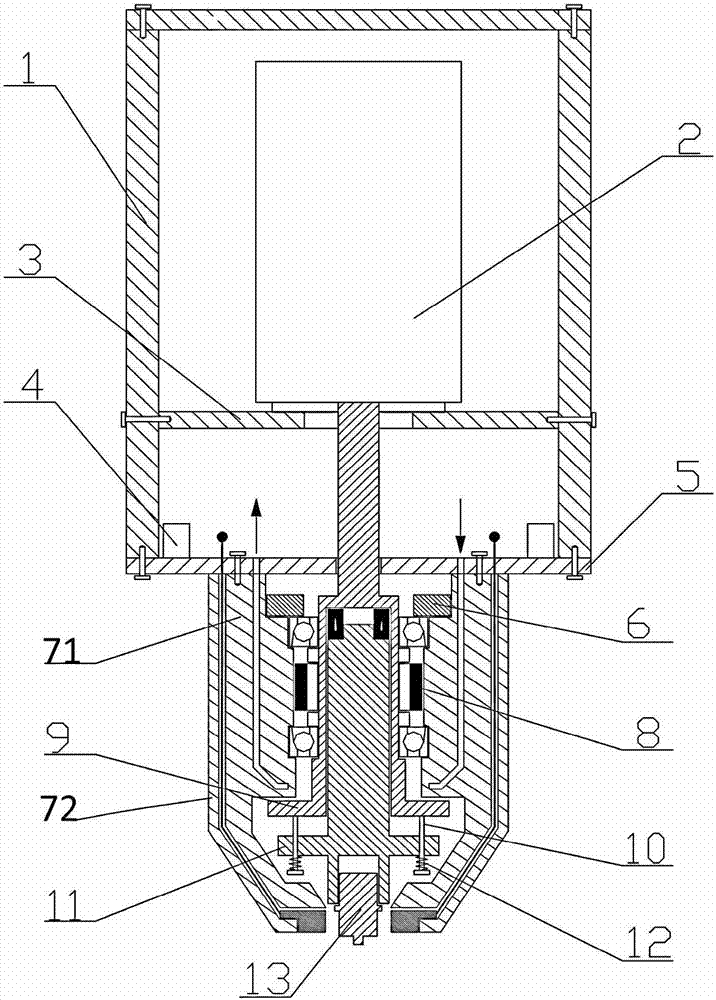

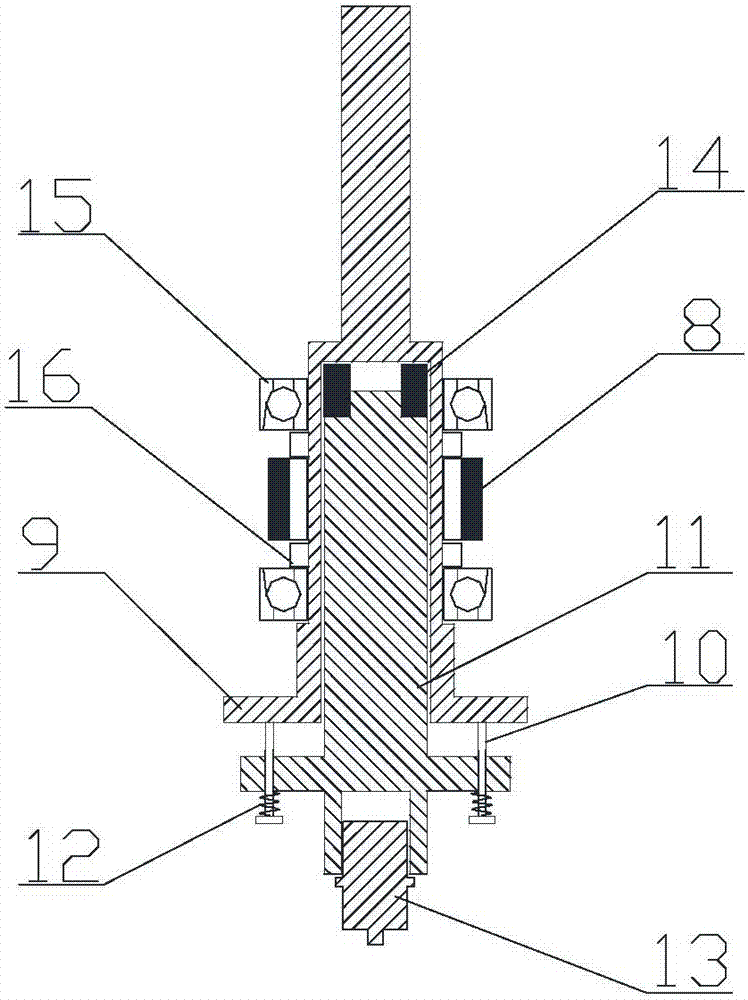

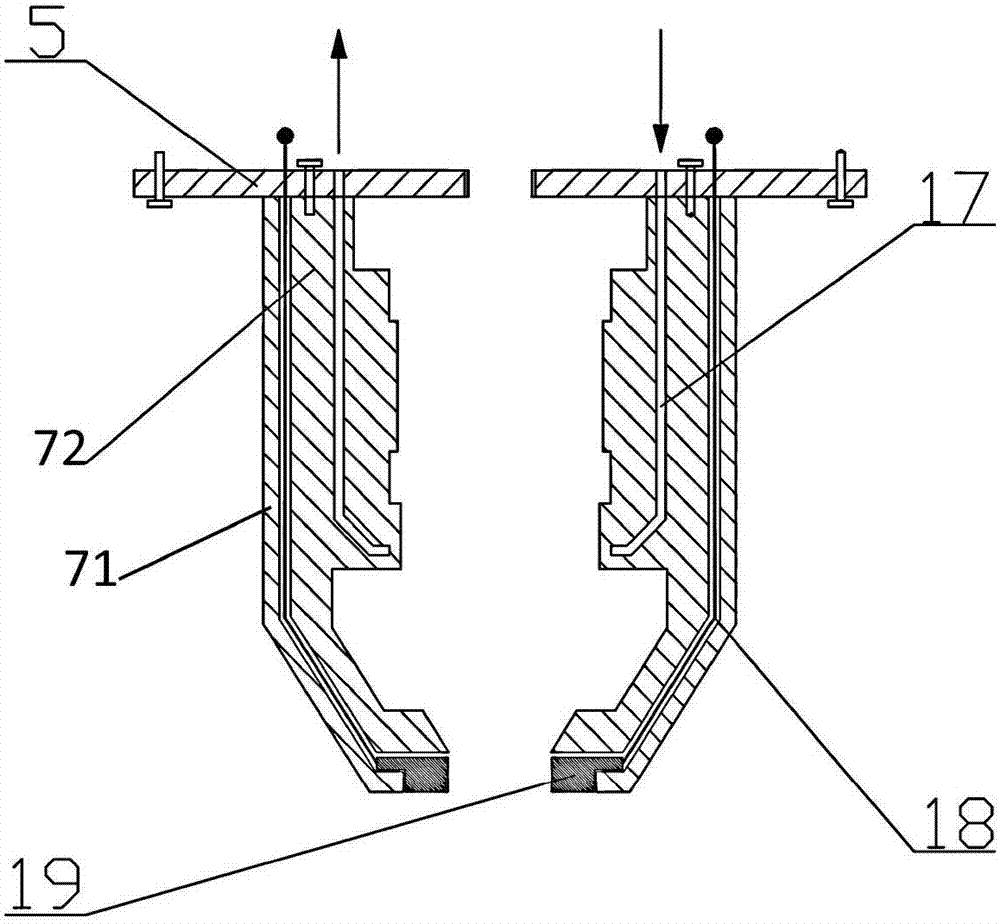

[0018] The applicant provides a composite heat-generating friction stir welding tool, which mainly includes a friction stir welding machine shell 1, a main motor 2, a first support frame 3, a vibration sensor 4, a second support frame 5, an annular retaining ring 6, Machine head inner shell 71, (welding machine) machine head shell 72, and pressure sensing system. Among them, the main structure of the pressure sensing system is as follows: slip ring 8, central shaft 9, circular guide rail 10, friction stir head rotating fixture 11, spring 12, friction stir head 13, pressure sensor 14, second bearing 15 and slip ring Positioning sleeve 16. The shell of the welder head mainly includes: a second support frame 5 , a shell of the welder head, a cooling water circulation inner cavity 17 , a resistive auxiliary heat source 18 and a copper heating head 19 .

[0019] The connection method, positional relationship and shape of the friction welding tool are described in detail below. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com