Assembly device and assembly method of grating ruler carriage and bearing

An assembly method and grating ruler technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complex structure of carriage, poor consistency, inconvenient operation process, etc., and achieve simple device structure, convenient operation, and high assembly efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

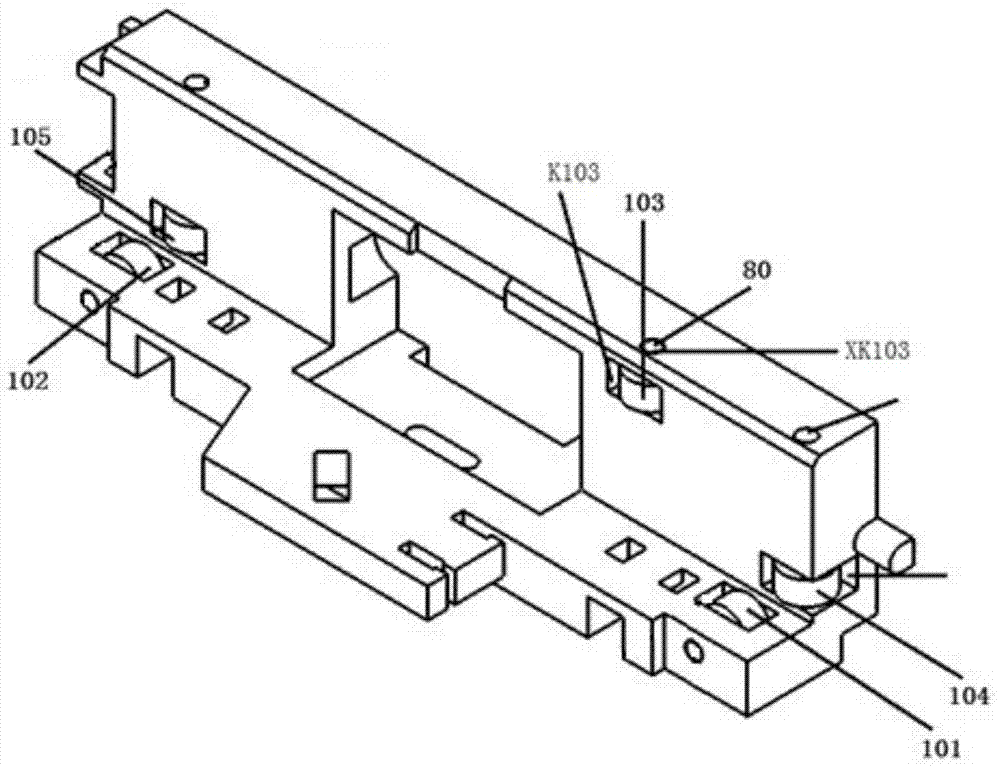

[0021] like figure 1 As shown, in the grating ruler carriage and bearing assembly device, the grating ruler carriage 10, the first bearing 101, the second bearing 102, the third bearing 103, the fourth bearing 104 and the fifth The bearing 105 has the same structure as the five bearings 101-105. The diameter of the outer ring of the bearing is 4mm, the diameter of the inner ring is 1.5mm, and the width is 2mm; the width of the bearing hole K103 corresponding to the third bearing 103 on the grating slider 10 is 2.5mm, and the diameter of the pin hole XK103 is 1.5mm.

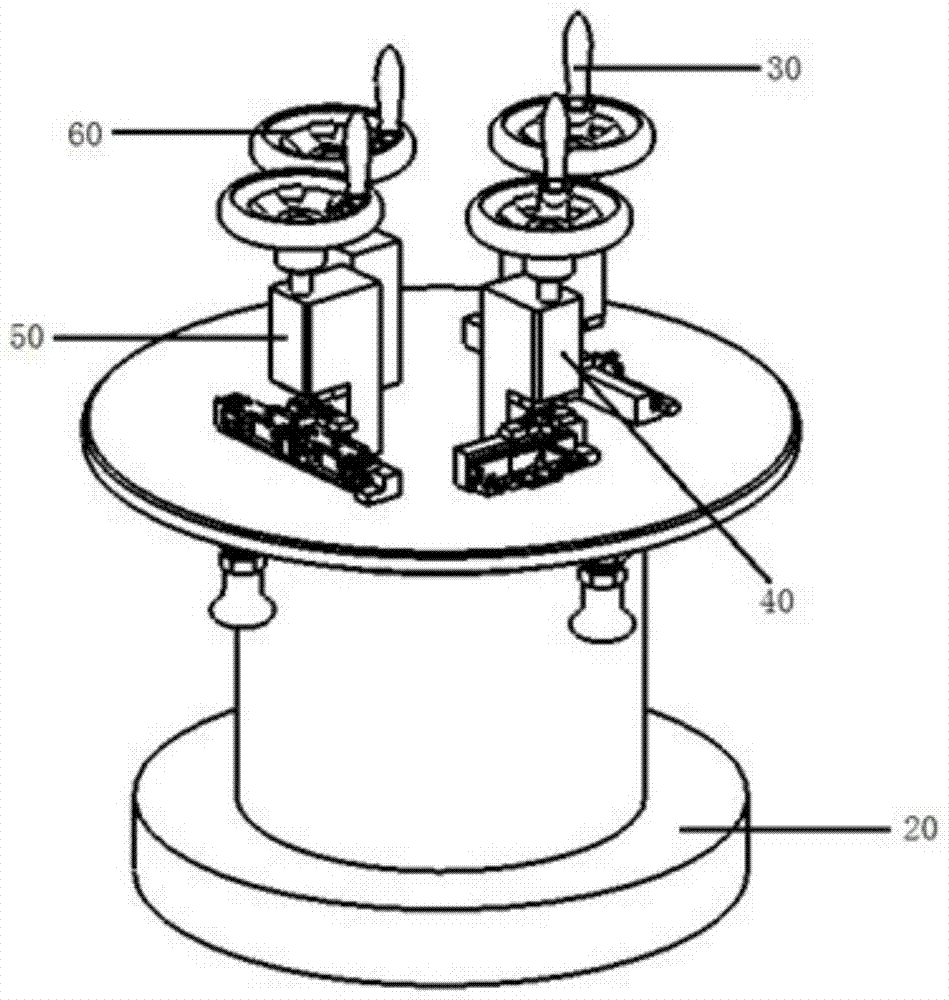

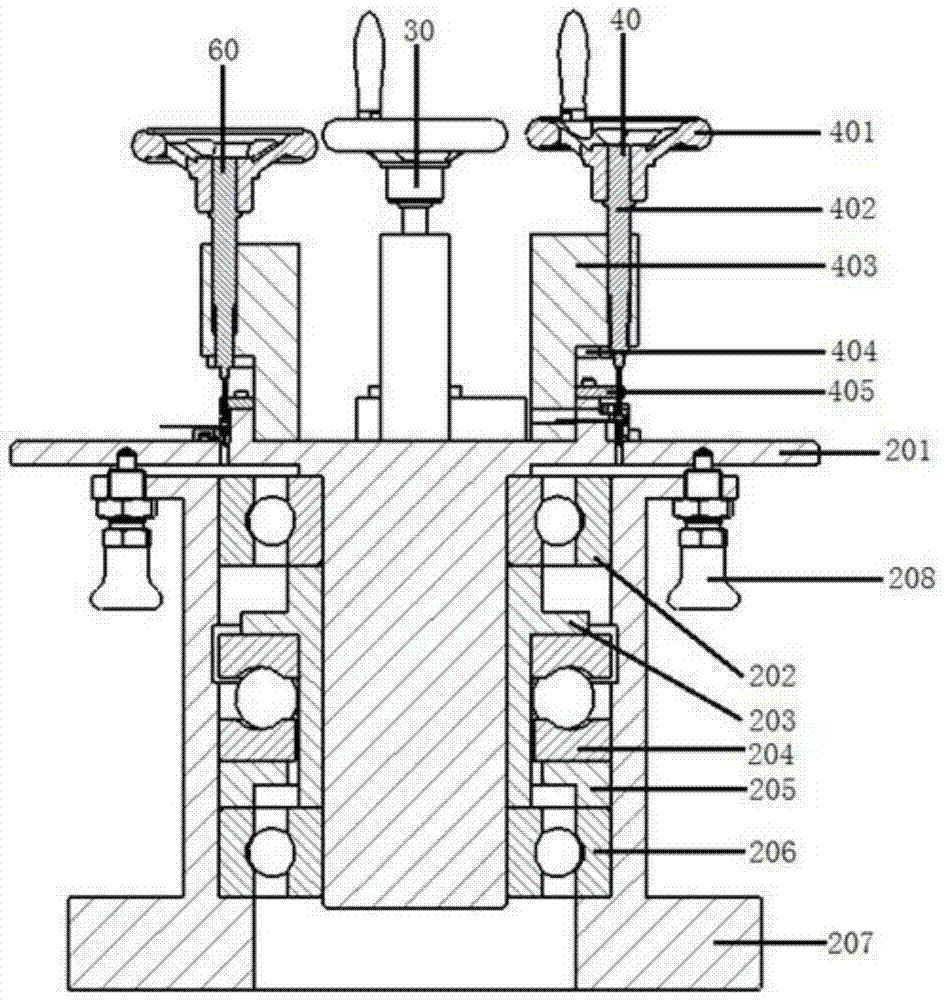

[0022] like figure 2 As shown, the grating ruler carriage and bearing assembly device is composed of a working position turntable 20 , a first press-in mechanism 30 , a second press-in mechanism 40 , a third press-in mechanism 50 , a fourth press-in mechanism 60 , and an insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com