A bearing installation device

A technology for installing devices and bearings, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting bearing installation accuracy, uncontrollable pressure and feedback, affecting bearing working clearance, noise, rotation accuracy and life. , to achieve the effect of improving installation quality and ensuring position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

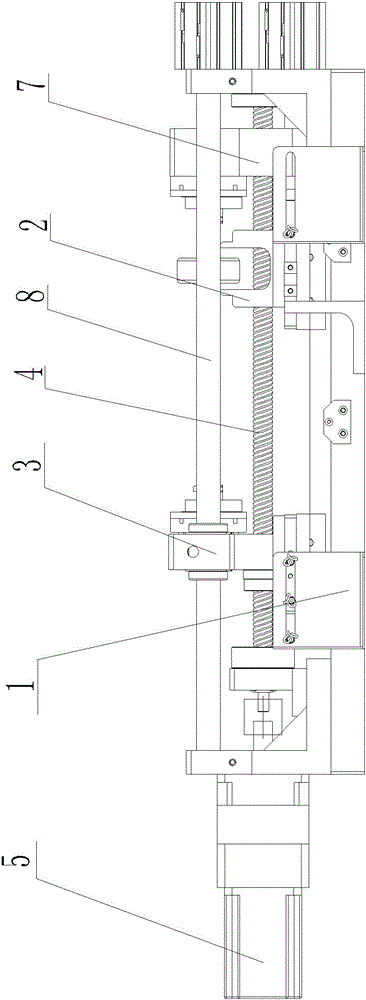

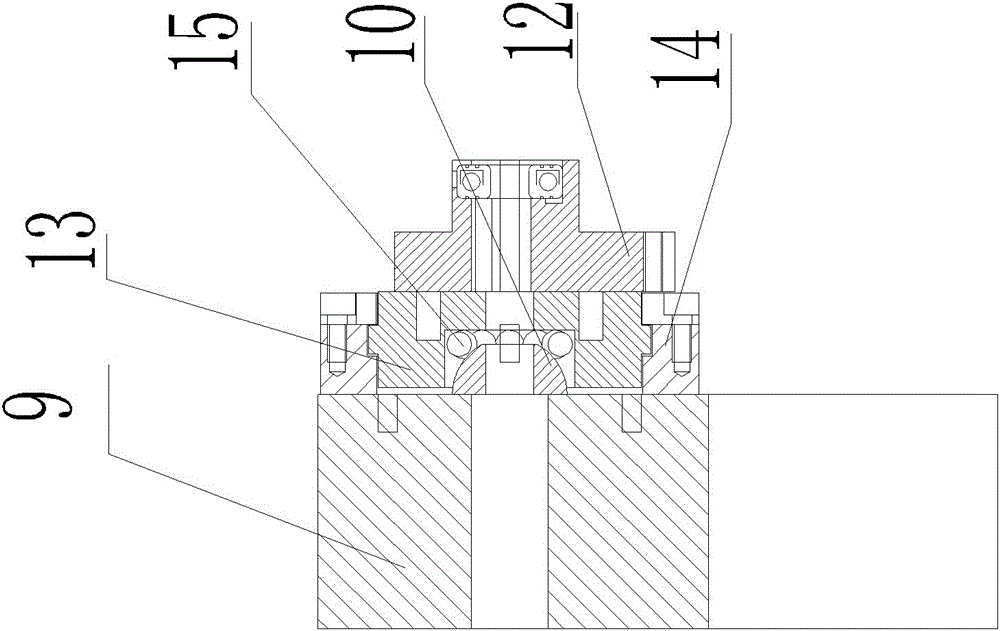

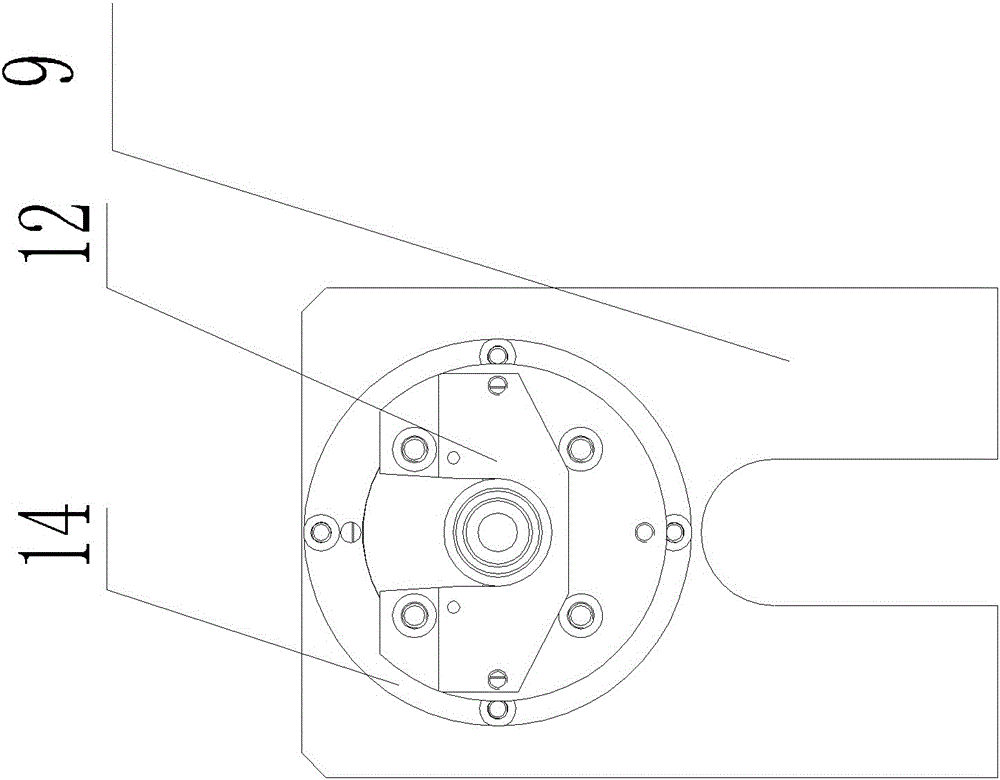

[0014] A bearing installation device, which includes a base 1, a shaft support seat 2 is arranged on the base 1, a bearing support seat 3 is provided on the base 1 corresponding to the shaft support seat 2, the bearing support seat 3 is slidingly connected with the base 1, and the bearing support seat 3 Connect the ball screw 4, the ball screw 4 is connected to the servo motor 5, the ball screw 4 rotates to drive the bearing support seat 3 to move, and the moving bearing support seat 3 drives the bearing 6-1 to press into the transmission shaft 11 on the shaft support seat 2 middle;

Embodiment 2

[0016] A bearing installation device, which includes a base 1, a shaft support seat 2 is arranged on the base 1, a bearing support seat 3 is provided on the base 1 corresponding to the shaft support seat 2, the bearing support seat 3 is slidingly connected with the base 1, and the bearing support seat 3 Connect the ball screw 4, the ball screw 4 is connected to the servo motor 5, the shaft support seat 2 is slidingly connected with the base 1, the shaft support seat 2 is connected to the movable jacking cylinder (not shown in the figure), and the corresponding bearing support seat 3 is on the shaft support seat The other end of 2 is provided with a second bearing support seat 7. Through the tightening and shrinking actions of the jacking cylinder (not shown in the figure), the shaft support seat 2 can be moved and fixed, and the bearings 6 at both ends of the transmission shaft 1 can be realized. 1. 6-2 press-in.

[0017] The bearing support seat 3 is connected to the base 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com