Continuous monitoring flexible pressure sensor and composite film layer production method

A pressure sensor and composite film technology, applied in the field of flexible sensors, can solve the problems of large signal interference, difficulty in detecting pressure changes, unfavorable system continuous operation, etc., and achieve the effects of improving detection sensitivity, large voltage amplitude and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

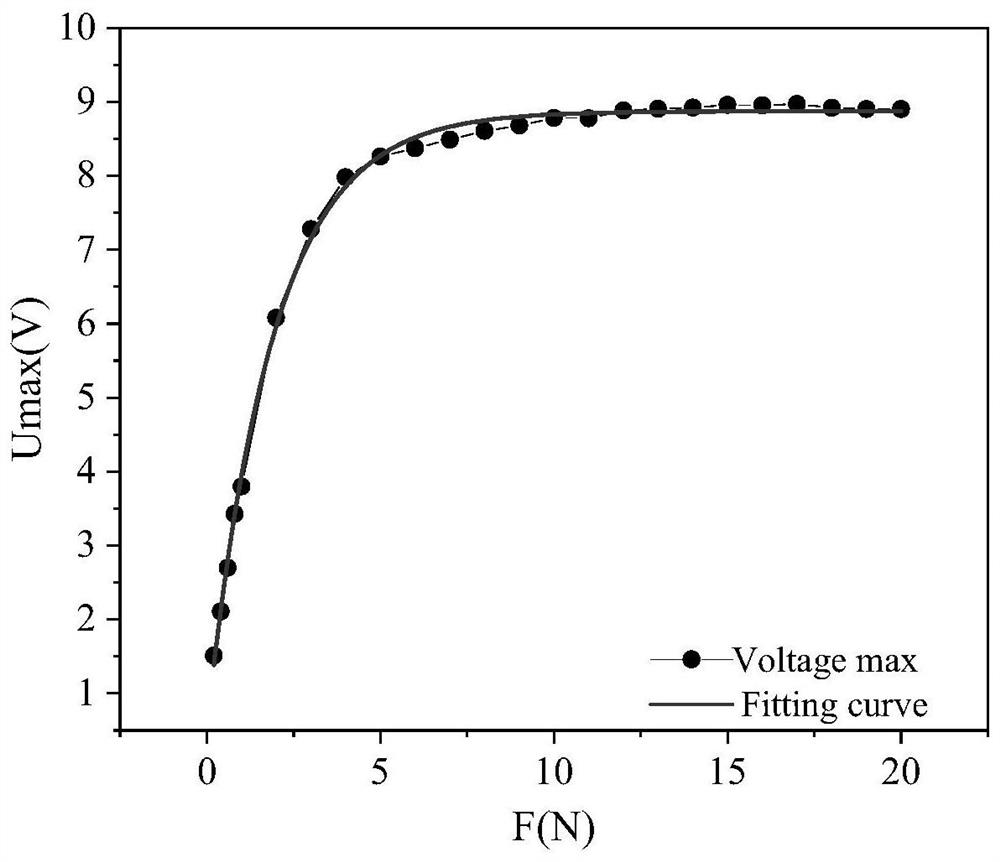

[0047] Such as image 3 As shown, when the sensor is used as an electronic skin or a pressure sensor for pressure detection, the sensor can quantify the detected pressure value by corresponding to the pressure and voltage in the range of 0-5N. When the contact area is 20mm*20mm, The change trend of the output voltage peak value with the pressure of 0.2-20N is obtained after fitting, which basically conforms to the formula

[0048] u (F) =a-b*c F As a result of (1), the fitting determination coefficient is 0.998, where a=8.87, b=8.32, c=0.89, according to the formula (1), the pressure detection value can be quantified, and the external force on the flexible electronic skin can be calculated , so as to realize the determination of the pressure value by the pressure sensor.

Embodiment 2

[0050] Such as Figure 4 As shown, when the sensor performs continuous pressure monitoring, three different forces (light touch, light pressure, heavy pressure) and periodic pressure are used to touch the electronic skin, and the detection output voltage of the three pressures is applied after touching the electronic skin , the three different forces have voltages of 1.1V, 1.6V, and 2.4V respectively. After pressing the electronic skin and pressing it periodically, the output voltage will also change periodically. The applied force can be calculated by formula (1). The forces are 0.16N, 0.28N, and 0.49N respectively, which are consistent with the actual pressing conditions and the measurement results. The above results fully prove that when touching the outside of the sensor, the sensor can realize continuous detection of pressure and can Different output and different voltage values can meet the needs of daily pressure continuous detection and feedback. At the same time, th...

Embodiment 3

[0052] Such as Figure 5 As shown, when the pressure sensor is used for health monitoring, the pressure sensor is attached to the surface of the neck, the insulating material layer is in contact with the neck, and the pressure changes and muscle movements caused by the pulse and respiration act on the flexible pressure sensor electrode layer 1, so that the electrodes The composite film layer 2 under layer 1 is deformed, the output voltage produces a large peak voltage, and the pressure generated by the pulse action and the respiration action on the pressure sensor are different. The voltage value is between 1.2V-1.3V under the pulse action, and the respiration Under the action, the voltage value is about 1.6V, which can be distinguished. By monitoring the voltage amplitude and frequency, the monitoring of pulse, breathing and other physical health status can be realized.

[0053] The present invention utilizes the piezoelectric effect of polyvinylidene fluoride and silica gel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com