Simple large hole chamfering measurement tool

A measuring tool and chamfering technology, applied in the field of hole processing, can solve problems such as hidden dangers of engine assembly quality and safety, unqualified batch processing, and measurement errors, and achieve the effects of facilitating processing, improving measurement efficiency, and improving benchmark accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0033] Non-limiting and non-exclusive embodiments will be described with reference to the following drawings, wherein like reference numerals refer to like parts unless specifically stated otherwise.

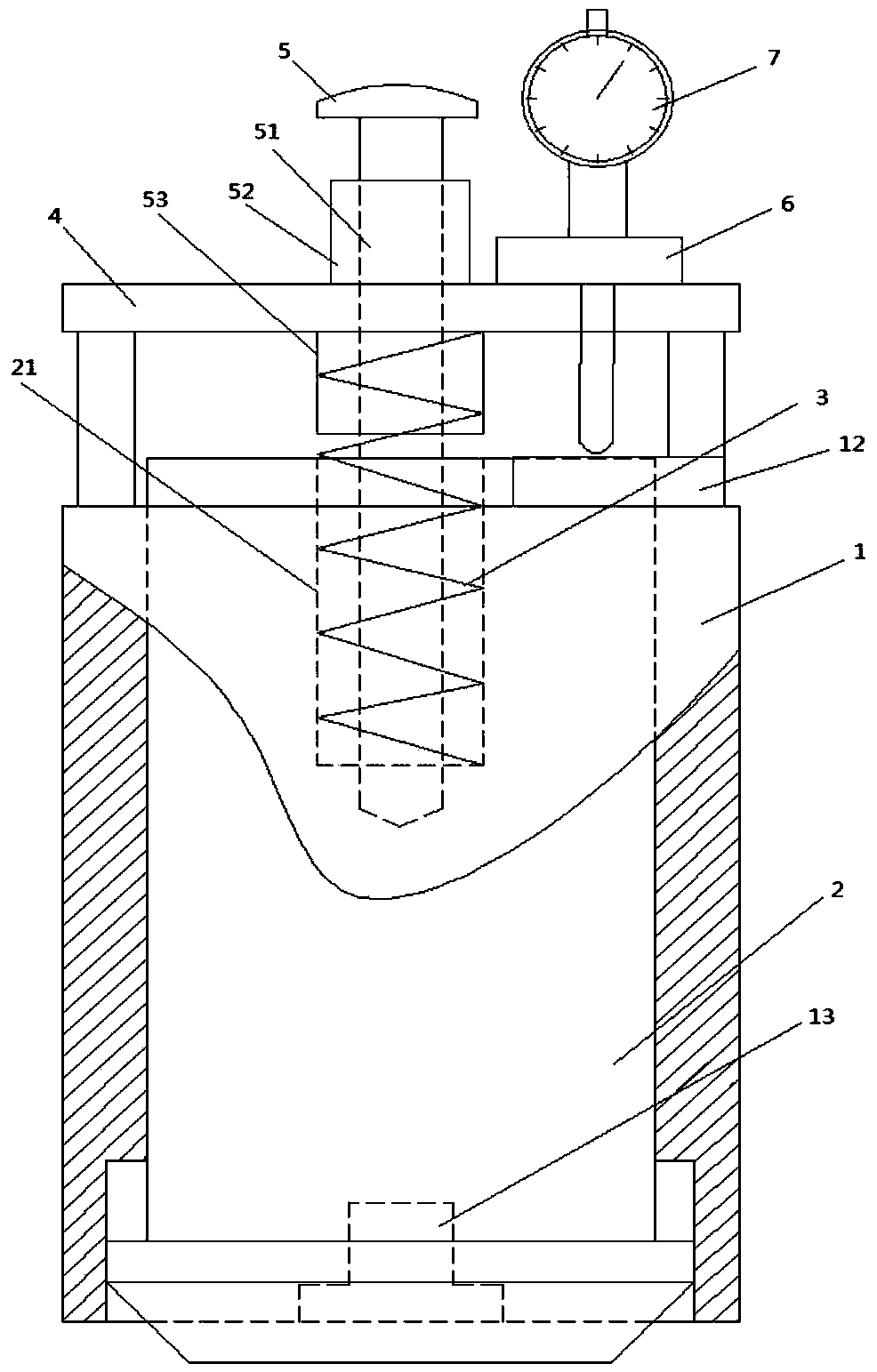

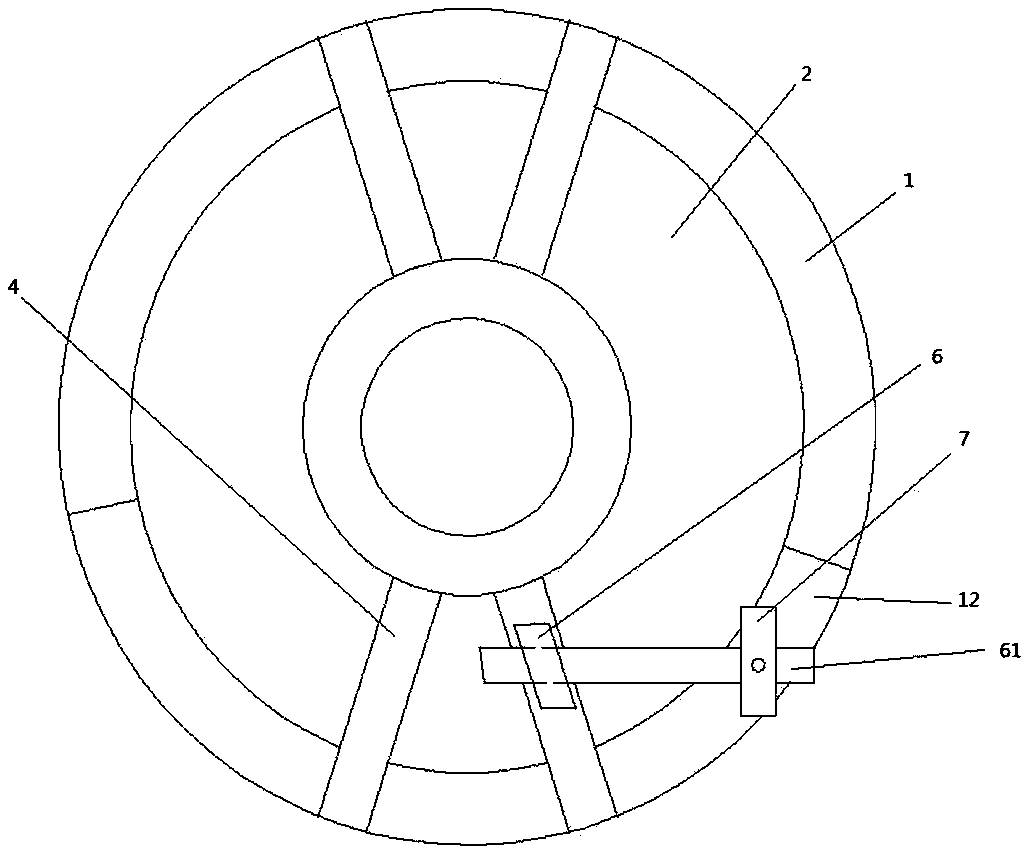

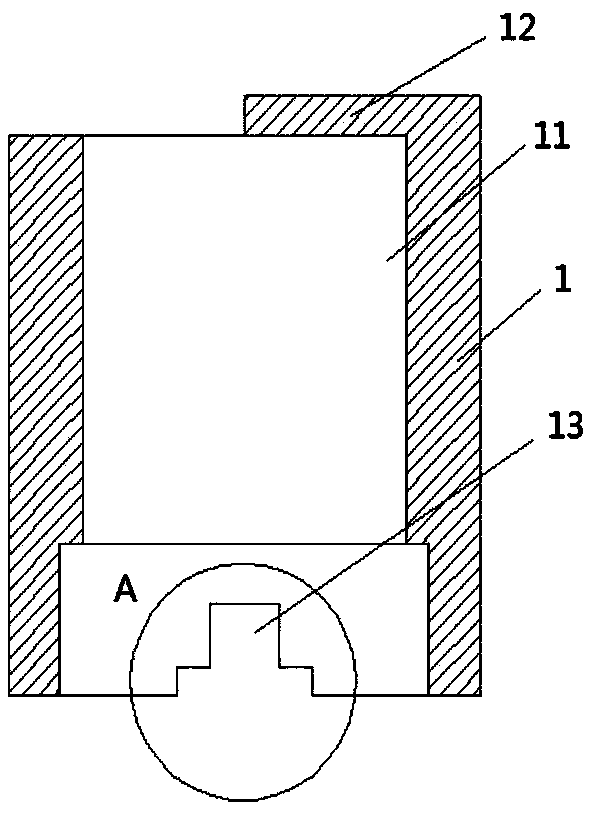

[0034] refer to Figure 1-4 A simple large-hole chamfering measuring tool shown includes a measuring sleeve 1 and a measuring mandrel 2. The measuring sleeve 1 is provided with an axial countersunk guide hole 11, and the upper part of the measuring sleeve 1 is provided with a step 12. The step 12 The height is the conversion value of the diameter tolerance of the chamfer of the orifice to be measured. The measuring mandrel 2 is slidably arranged in the guide hole 11, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com