Multifunctional standard device for precision calibration of precision parts and equipment

A technology for precision parts and standards, applied in the field of multi-function standards, can solve problems such as single function of cylindrical test rods, and achieve the effects of rich measurement functions, convenient measurement, good market application scenarios and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution is described in detail in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the patent of the present invention, and are not used to limit the protection scope of the patent of the present invention.

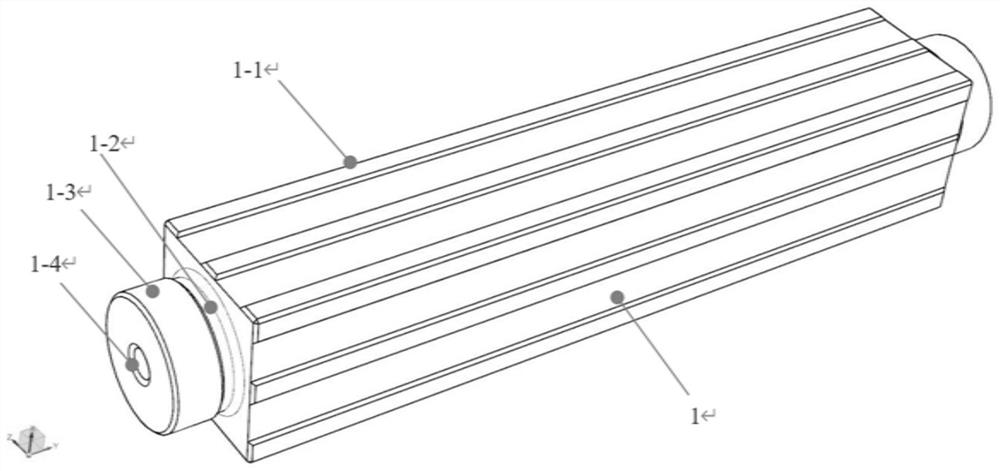

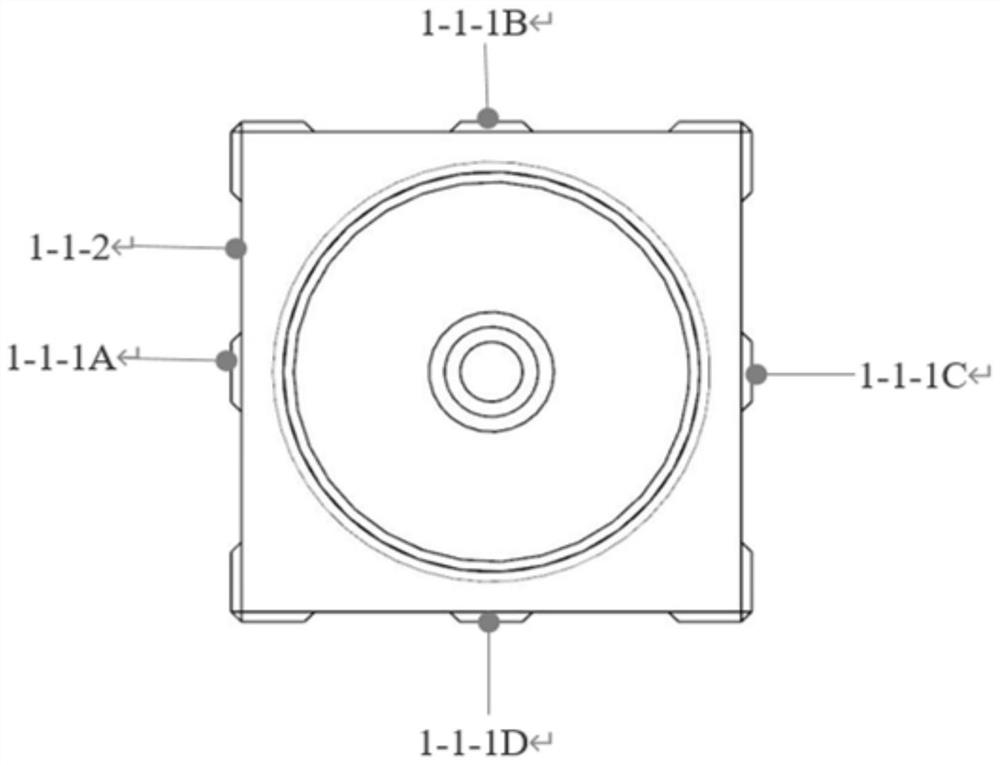

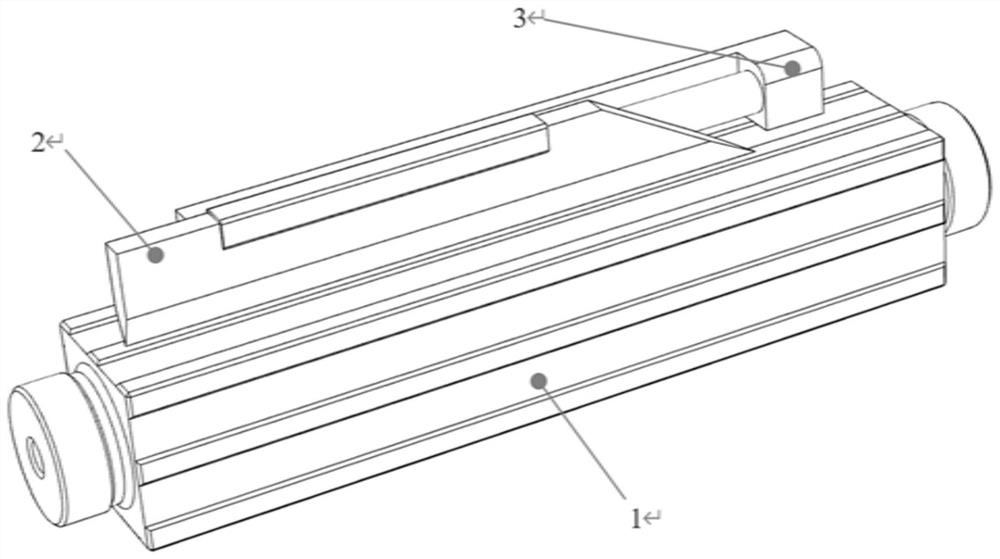

[0026] The multifunctional standard 1 is an overall symmetrical structure, the middle main part is a solid cuboid 1-1 with a rectangular groove, two radial reference cylindrical surfaces 1-3 and two central holes 1-1 are provided at both ends. 4. There is a grinding wheel overtravel groove 1-2 between the radial reference cylindrical surface 1-3 and the cuboid 1-1; the cuboid structure 1-1 on the multifunctional standard 1 has a symmetrical four-sided structure, and the adjacent two sides are perpendicular to each other. Parallel to each other, the three surfaces 1-1-1A, 1-1-1B, and 1-1-1C are finishing surfaces, and each surface is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com