High-speed braiding machine

A high-speed knitting machine and machine technology, applied in weft knitting, warp knitting, knitting and other directions, can solve the problems of inconvenient disassembly of the knitting machine runway groove, high accumulated error of parts, short service life, etc., and achieve increased rigidity and equipment performance. The effect of improved, high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

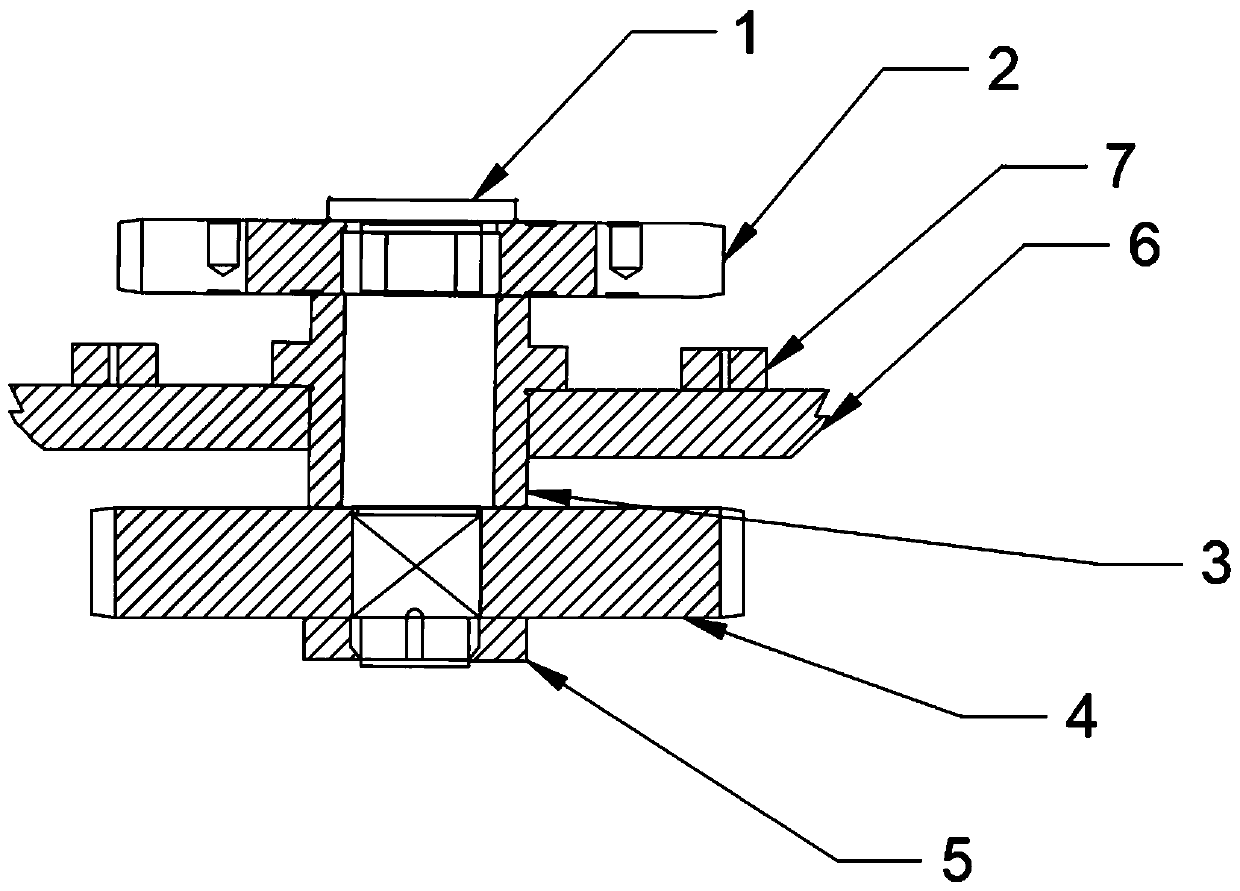

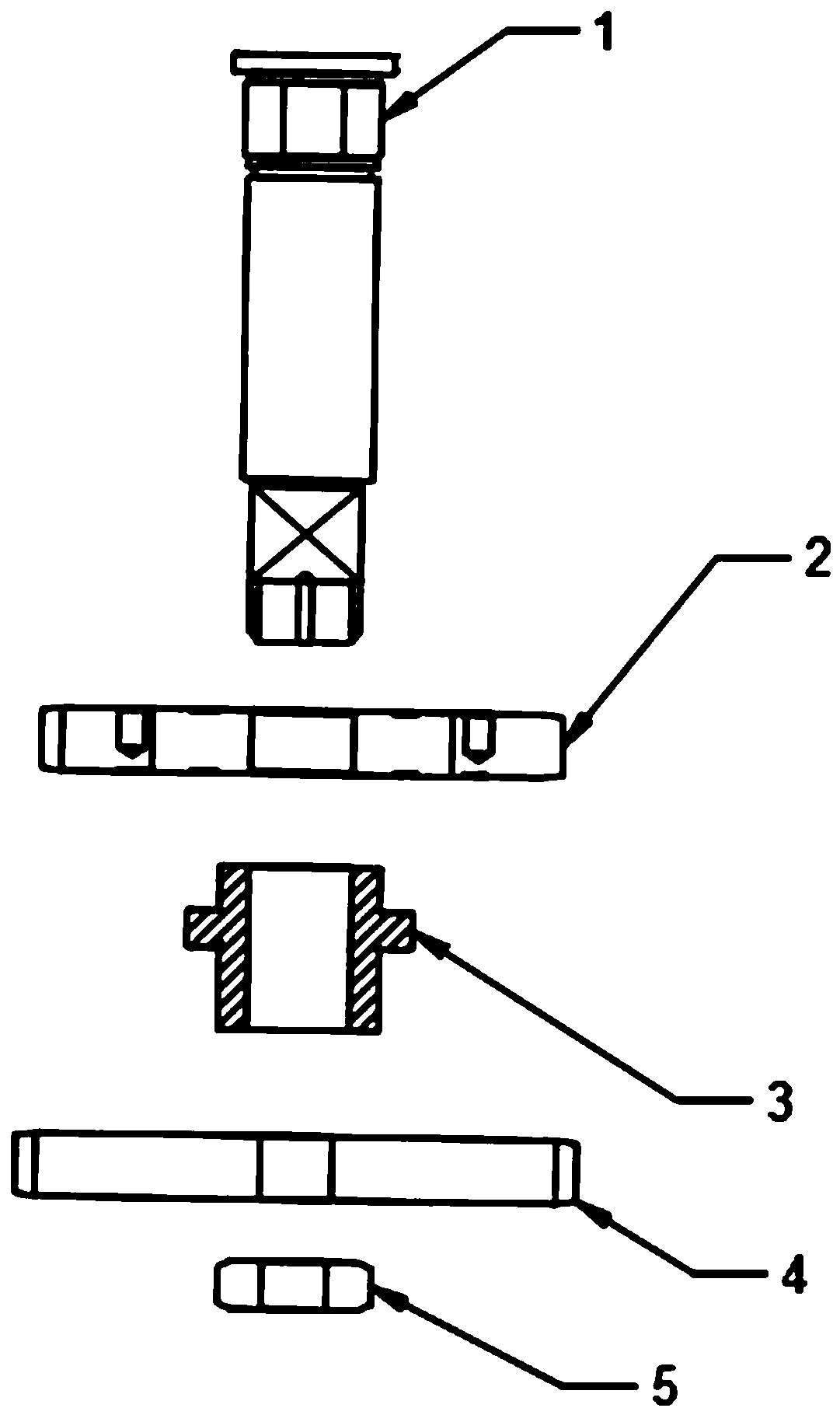

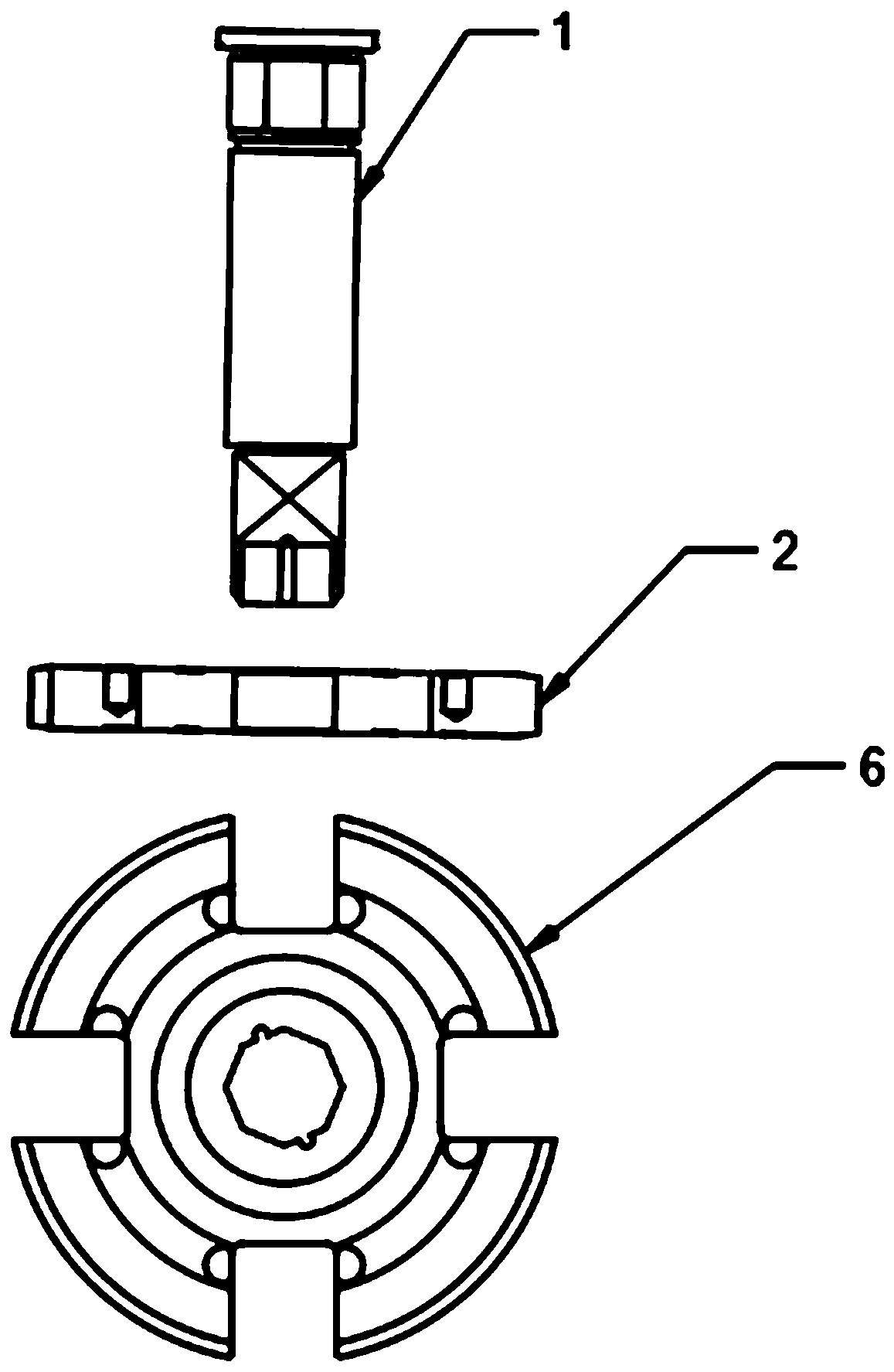

[0033] see Figure 1-Figure 9 , the present invention provides the following technical solutions: a high-speed braiding machine, including a rotor support shaft 1, a machine steel plate 6, the middle part of the machine steel plate 6 penetrates the rotor support sleeve 3, and the middle part of the rotor support sleeve 3 penetrates the rotor support shaft 1 The outer circumference of the rotor support shaft 1 is equipped with a combined rotor 2, the lower side of the machine steel plate 6 and the outer ring of the rotor support shaft 1 are equipped with a gear 4, and the outer ring of the rotor support shaft 1 and the lower side of the gear 4 are installed Have and tighten nut 5, the upper side of machine steel plate 6 is provided with runway groove 7, and the edge corner place of machine steel plate 6 is provided with support plate 11, and the rear side of support plate 11 is provided with oil groove 12.

[0034] In this embodiment: the outer ring 8 of the No. 1 runway, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com