A Laser Filler Welding Process of Magnesium/Al Dissimilar Metals

A dissimilar metal and filler welding technology, which is applied in laser welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of large heat input, welding deformation, and difficult to control the heating position, and achieve convenient and flexible operation , beautiful weld shape and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

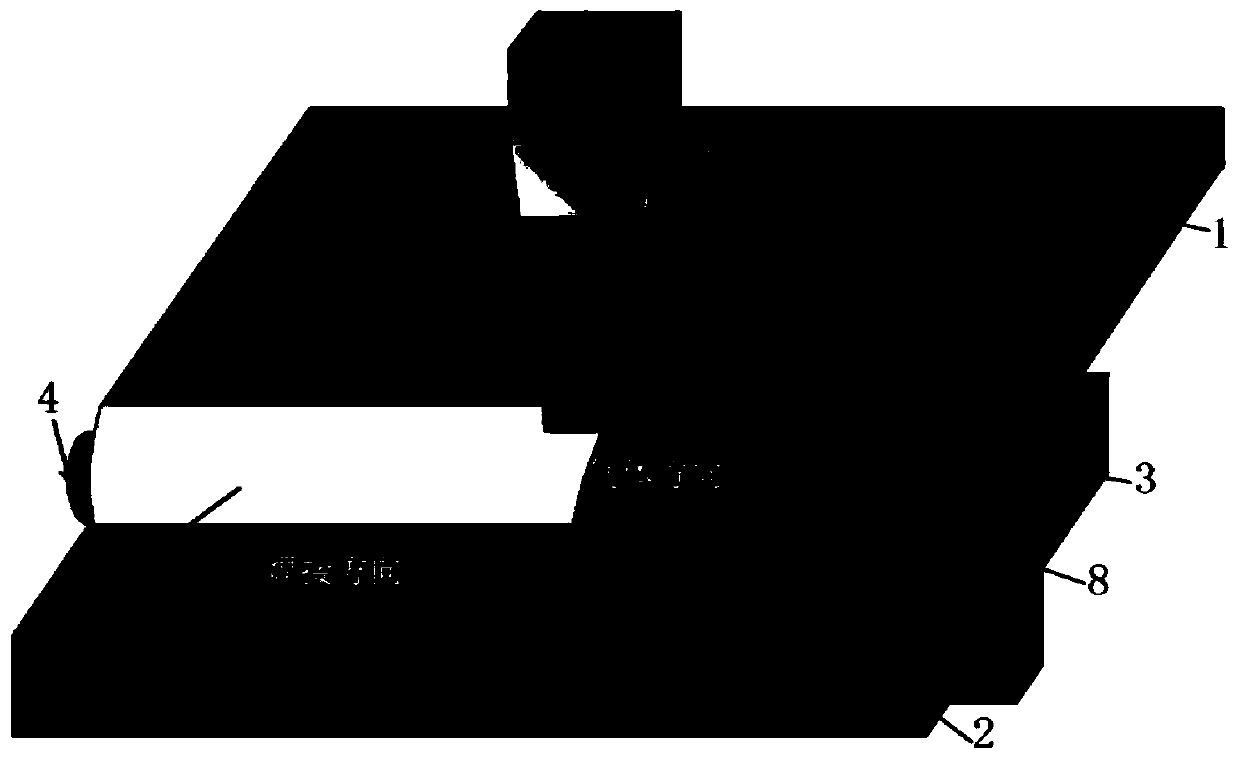

[0031] 1. Selection of welding consumables and intermediate layer

[0032] Magnesium alloy plate (ZEK100): size 60mm×50mm, thickness 1.5mm;

[0033] Aluminum alloy plate (AA5182): size 60mm×50mm, thickness 1.5mm;

[0034] Nickel foil: size 50mm×10mm, thickness 0.2mm, purity 99.9%;

[0035] Zn-Al alloy welding wire: diameter 1.6-2.0mm, the mass percentage of chemical elements in the wire is: Al 21.0%-23.0%, other elements 0.15-0.2%, and the rest is Zn; among them, other elements are Zn- Other components allowed in Al alloy welding wire have no effect on the welding reaction of the main components zinc and aluminum.

[0036]Flux: Superior No.20 (Superior Flux&Mfg.Co.), its composition mass percentage is: LiCl35%~40%, KCl 30%~35%, NaF 10%~21%, NaCl 8%~13%, ZnCl 2 6% to 10%.

[0037] 2. Preparation before welding

[0038] (1) Surface cleaning and flux solution preparation

[0039] Surface cleaning of the aluminum alloy plate: (1) soak the aluminum alloy plate in a 10% to 15%...

Embodiment 2

[0062] 1. Selection of welding consumables and intermediate layer

[0063] Same as Example 1.

[0064] 2. Preparation before welding

[0065] (1) Surface cleaning and flux solution preparation

[0066] The surface cleaning method and the preparation method of the flux solution are the same as in Example 1.

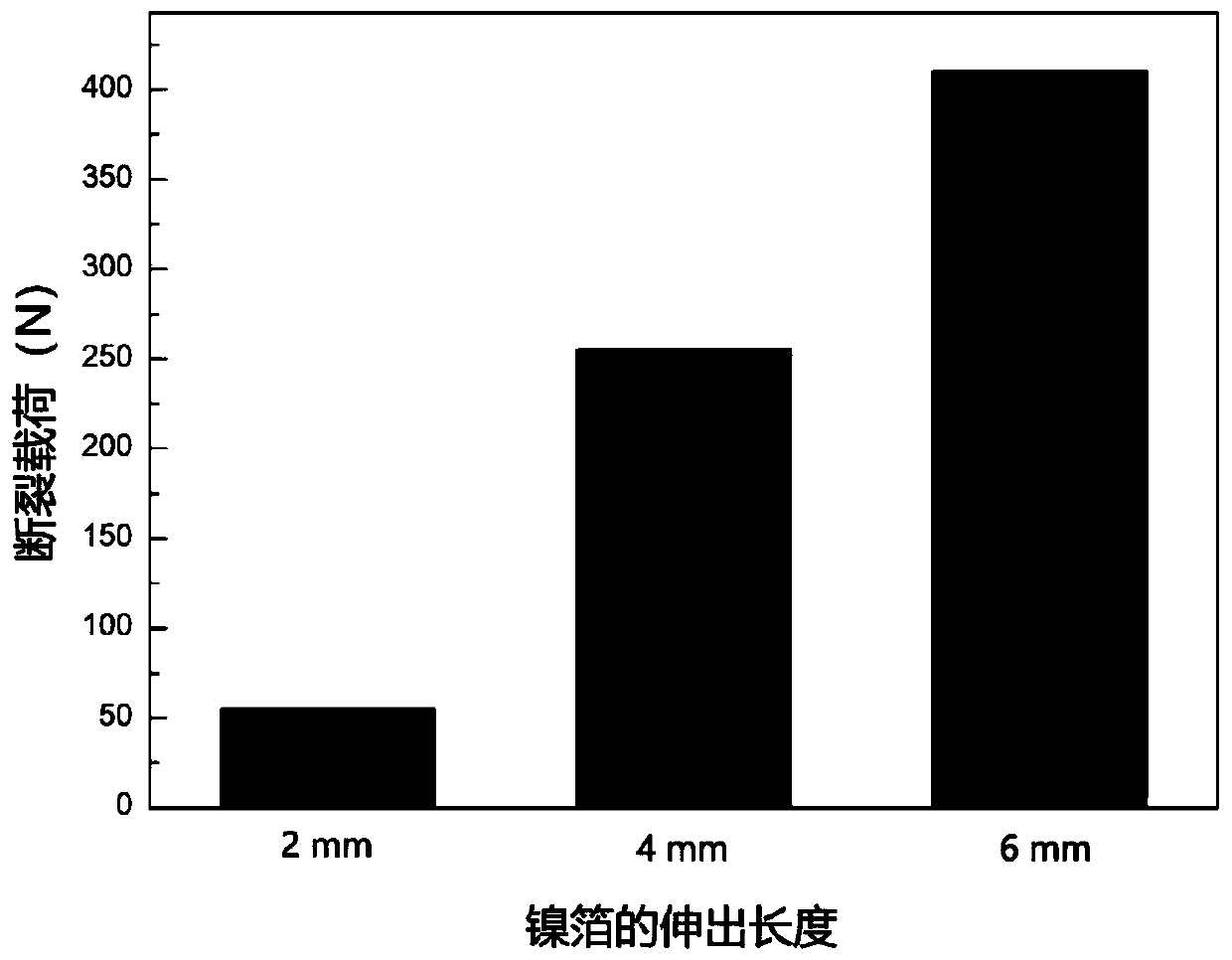

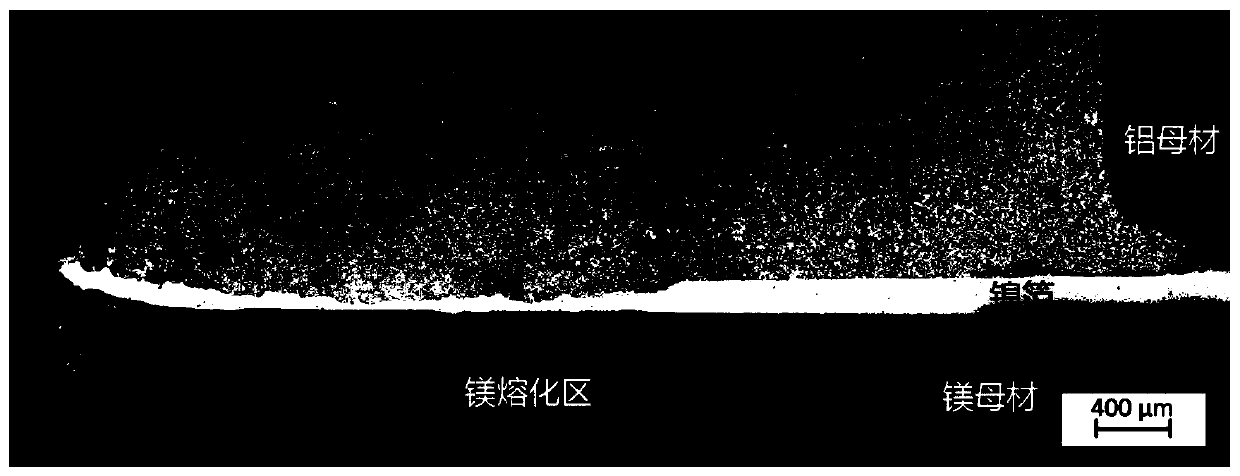

[0067] (2) Overlap

[0068] The overlapping method is the same as in Example 1, except that the difference from Example 1 is that the length of the overlapped joint between the nickel foil inserted into the magnesium alloy plate and the aluminum alloy plate is 6 mm, and the remaining 4 mm extends out of the magnesium alloy plate and the aluminum alloy plate. Overlapped joints.

[0069] 3. Welding

[0070] The welding method is the same as in Example 1, except that the laser parameters are: laser power 2.4kW, welding speed 0.24m / min.

[0071] 4. Post-welding treatment

[0072] (1) Cooling after welding: the method is the same as in Example 1.

[0073] (2) Clean up a...

Embodiment 3

[0080] 1. Selection of welding consumables and intermediate layer: the same as in Example 1.

[0081] 2. Preparation before welding

[0082] (1) Surface cleaning and flux solution preparation: the surface cleaning method and flux solution preparation method are the same as in Example 1.

[0083] (2) Overlap

[0084] The lapping method is the same as in Example 1, except that the difference from Example 1 is that the length of the overlapping overlapping parts of the nickel foil inserted into the magnesium alloy plate and the aluminum alloy plate is 4 mm, and the remaining 6 mm extends out of the magnesium alloy plate and the aluminum alloy plate. Overlapped joints.

[0085] 3. Welding

[0086] The welding method is the same as in Example 1, except that the laser parameters are: laser power 2.0kW, welding speed 0.28m / min.

[0087] 4. Post-welding treatment

[0088] (1) Cooling after welding: the method is the same as in Example 1.

[0089] (2) Clean up after welding: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com