Method for improving arc additive manufacturing precision and forming efficiency of wire material

A technology of additive manufacturing and electric arc, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve problems such as uneven layer height, layer height change, and reduced cladding deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

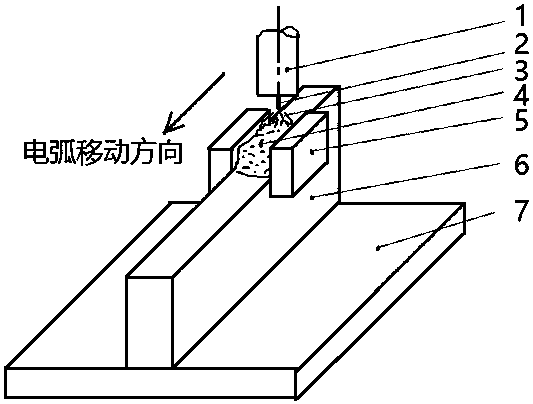

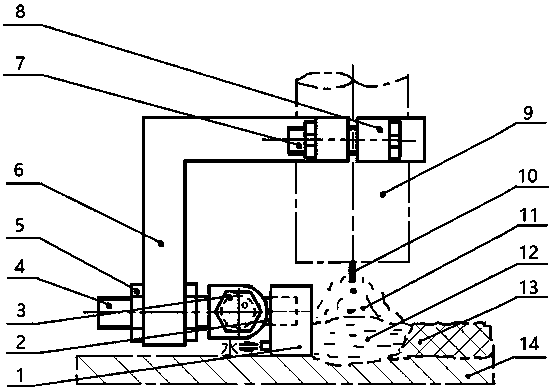

[0026] image 3 The assembly diagram of the one-sided forming device for the additive manufacturing of thick and large samples, the forming die (1) is installed on the connecting rod (2) through threaded connection, and the connecting rod (2) and the extension rod (4) are clamped by the bolt nut ( 3) Connect and fix, and use the nut (5) to clamp and install on the bracket (6), and the bracket (6) is fixed to the nozzle (9) of the welding torch by using the clamp (8) and the bolt and nut (7). Figure 4 This is an example of the mold shape and size used. Loosen the bolt and nut (7) to adjust the position of the fixture (8) and bracket (6) on the welding torch nozzle (9), thereby adjusting the distance from the nozzle to the surface of the workpiece during forming. Loosen the nut (5) to adjust the position of the extension rod (4) left and right, thereby adjusting the width of the weld bead. Loosen the nut (3) clamping the connecting rod (2) and the extension rod (4), so that t...

Embodiment 2

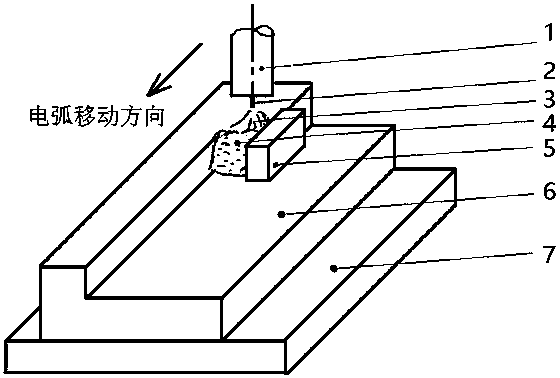

[0028] Figure 5The assembly diagram of the double-sided forming die device for the additive manufacturing of thin-walled samples, the forming dies and supports on both sides are symmetrical, the forming die (1) is installed on the connecting rod (2) through threaded connection, and the connecting rod (2) and the extension rod (4) Connect and fix by clamping bolts and nuts (3), and use the nuts (5) to clamp and install on the bracket (6), and the brackets (6) on both sides are fixed to the nozzle (8) of the welding torch by using the bolts and nuts (7) superior. The position of the bracket (6) on the welding torch nozzle (8) can be adjusted by loosening the bolt and nut (7), thereby adjusting the distance from the nozzle to the surface of the workpiece during forming. Loosen the nut (5) to adjust the position of the extension rod (4) left and right, thereby adjusting the width of the weld bead. Loosen the nut (3) clamping the connecting rod (2) and the extension rod (4), so ...

Embodiment 3

[0030] When the moving path of the arc is a circular arc, such as when forming thin-walled cylindrical parts, the mold fixture still uses Figure 5 As shown in the device, the forming die adopts Image 6 , Figure 7 As shown in the structure, the outer wall of the cylinder adopts Image 6 The mold shown, the inner wall of the cylinder adopts Figure 7 mold shown. Select according to the radius and wall thickness of the forming cylinder Image 6 and Figure 7 The arc radius r of the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com