Adhesive joint type perovskite manganese oxide material

A manganese oxide and perovskite technology, applied in the field of adhesive perovskite manganese oxide materials, can solve the problems of high preparation cost, poor mechanical properties, difficult reprocessing, etc., and achieves low preparation cost, improved toughness, Good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of embodiment of the present invention is, a kind of bonding type perovskite manganese oxide material is obtained by the following method:

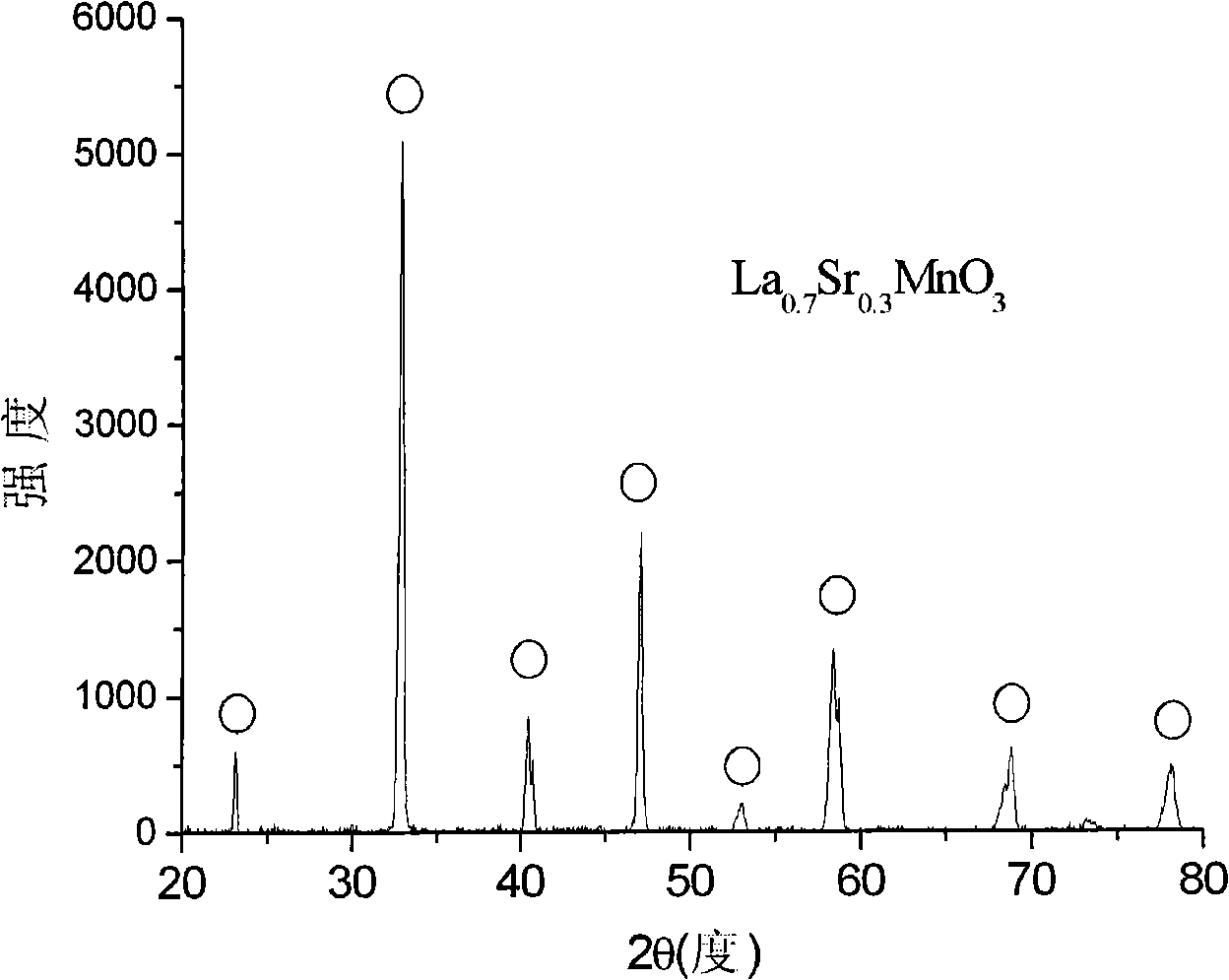

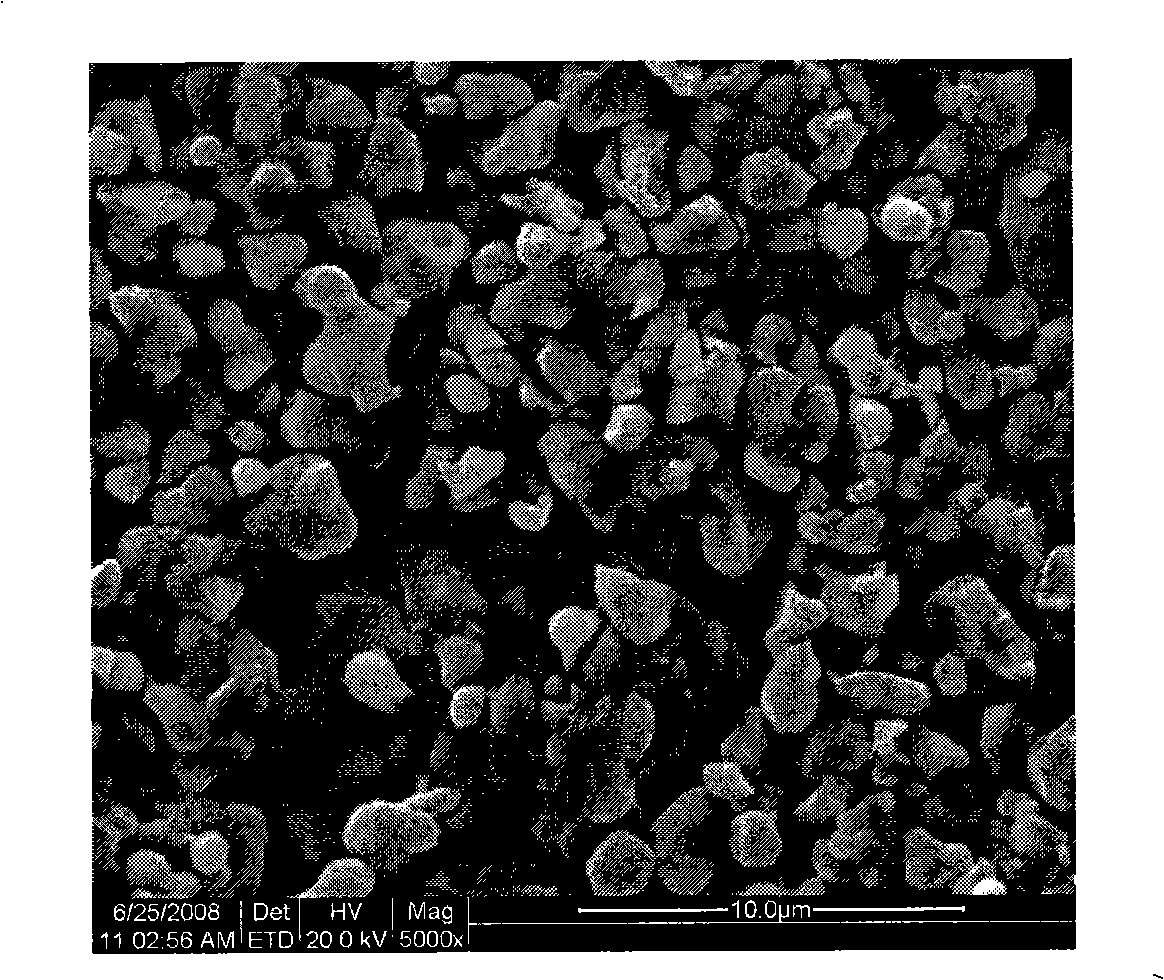

[0022] a, preparation of precursor powder will La 2 o 3 , SrCO 3 , MnO 2 According to the molecular formula La 1-x m x MnO 3 X = 0.3 atomic ratio ingredients, wherein M is Sr, after grinding the prepared raw materials, calcination and grinding after calcination are carried out 3 times, each time the calcination temperature is 1200 ° C for 10 hours, to obtain La 0.7 Sr 0.3 MnO 3 Precursor powder.

[0023] b. Coupling agent coating Fully mix the precursor powder in step a with 1% silane coupling agent by weight of the precursor powder, and stir evenly.

[0024] c. Bonding Dissolve the epoxy resin adhesive with 1% weight of the precursor powder and the curing agent matched with the epoxy resin adhesive in sequence in the acetone solution, and then add the coupling agent coated in step b. Precursor powder, mixed evenl...

Embodiment 2

[0027] A bonding type perovskite manganese oxide material is obtained by the following method:

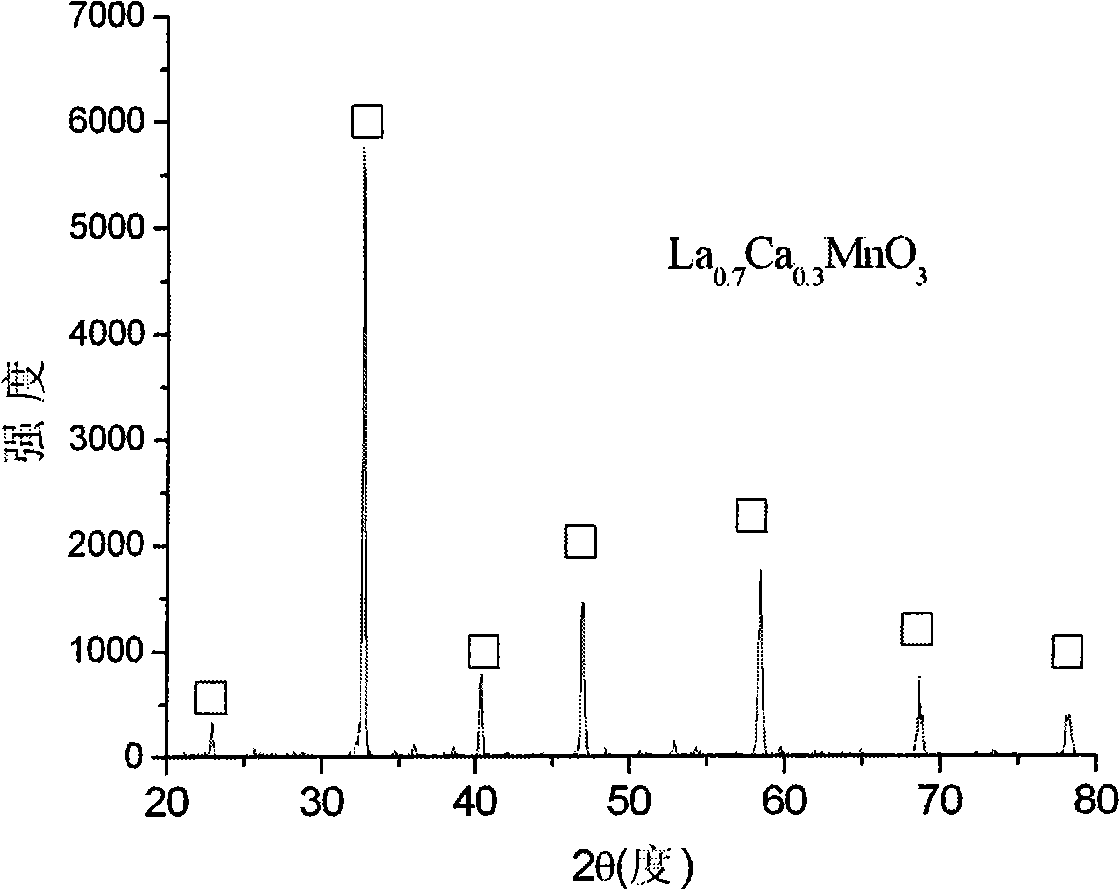

[0028] a. Preparation of precursor powder: La 2 o 3 , CaCO 3 , MnO 2 According to the molecular formula La 1-x m x MnO 3 The atomic ratio of X=0.3 is equipped with raw materials, wherein M is Ca. After grinding the prepared raw materials, 3 times of calcination and grinding after calcination, the calcination temperature of each time is 1200 ° C for 10 hours, to obtain La 0.7 Ca 0.3 MnO 3 Precursor powder.

[0029] b. Coupling agent coating Fully mix the precursor powder in step a with 1% silane coupling agent by weight of the precursor powder, and stir evenly.

[0030] c. Bonding Dissolve the epoxy resin adhesive with 3% precursor powder weight and the curing agent matched with the epoxy resin adhesive in sequence in the acetone solution, and then add the b-step coupling agent coated Precursor powder, mixed evenly, dried at 150°C, and pressed under a pressure of 50Mpa. ...

Embodiment 3

[0033] A bonding type perovskite manganese oxide material is obtained by the following method:

[0034] a. Preparation of precursor powder: La 2 o 3 、Co 2 o 3 , MnO 2 According to the molecular formula La 1-x m x MnO 3 The atomic ratio of X=0.9 is equipped with raw materials, wherein M is Co. After grinding the prepared raw materials, the prepared raw materials are ground, and then calcination and grinding after calcination are carried out twice. The calcination temperature of each time is 1100°C. 5 hours, that is La 0.1 co 0.9 MnO 3 Precursor powder.

[0035] b. Precursor powder coated with coupling agent Fully mix the precursor powder in step a with 0.5% silane coupling agent by weight of the precursor powder, and stir evenly.

[0036] c. Bonding of precursor powder Dissolve the epoxy resin adhesive of 6% precursor powder weight and the curing agent matched with the epoxy resin adhesive in sequence in the acetone solution, and then add the coupling agent package ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com