Nanoimprint machine and pressurizing method thereof

An imprinter and nanotechnology, applied in optomechanical equipment, optics, instruments, etc., can solve the problems of uneven pressure distribution and poor adaptability, and achieve the effect of uniform pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

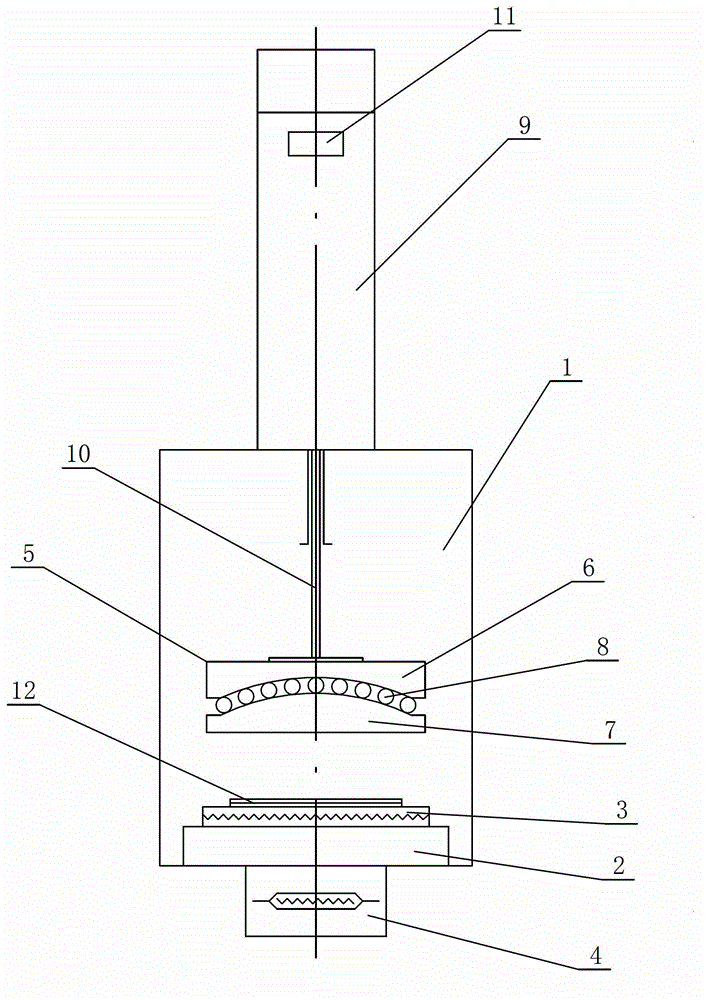

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] see figure 1 as shown, figure 1 It is a schematic structural diagram of the nanoimprint machine provided in Embodiment 1 of the present invention.

[0022] In this embodiment, a nanoimprinting machine includes a vacuum chamber 1, a pressure-bearing platform 2 is provided at the bottom of the vacuum chamber 1, and the pressure-bearing platform 2 is made of any one of stainless steel or quartz glass, and The pressure-bearing platform 2 is provided with an electric heating furnace 3 with a built-in water-cooling circulation system, and its bottom is provided with an ultraviolet light source 4 with a wavelength of 375nm. According to different experimental requirements, either thermosetting or ultraviolet curing can be selected. A forming method, a pressure plate 5 is arranged above the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com