Active washboard fluidized bed pipeline for powder material transportation and method of use thereof

A powder material and fluidized bed technology, applied in the direction of conveyors, transportation and packaging, and conveying bulk materials, etc., can solve the problems of pipeline blockage, failure to fill curing agent, and easy blockage of feeding channels, etc., to improve construction efficiency and construction quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

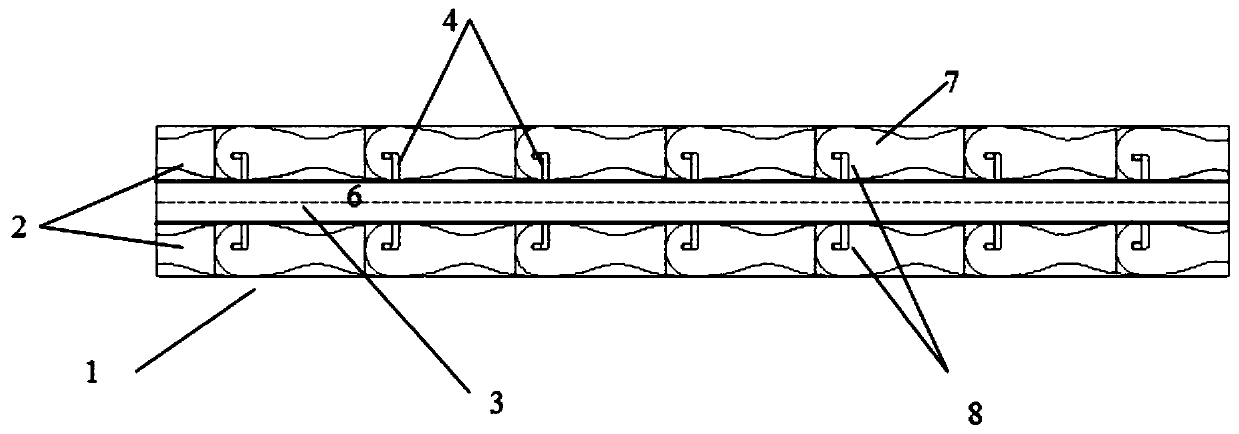

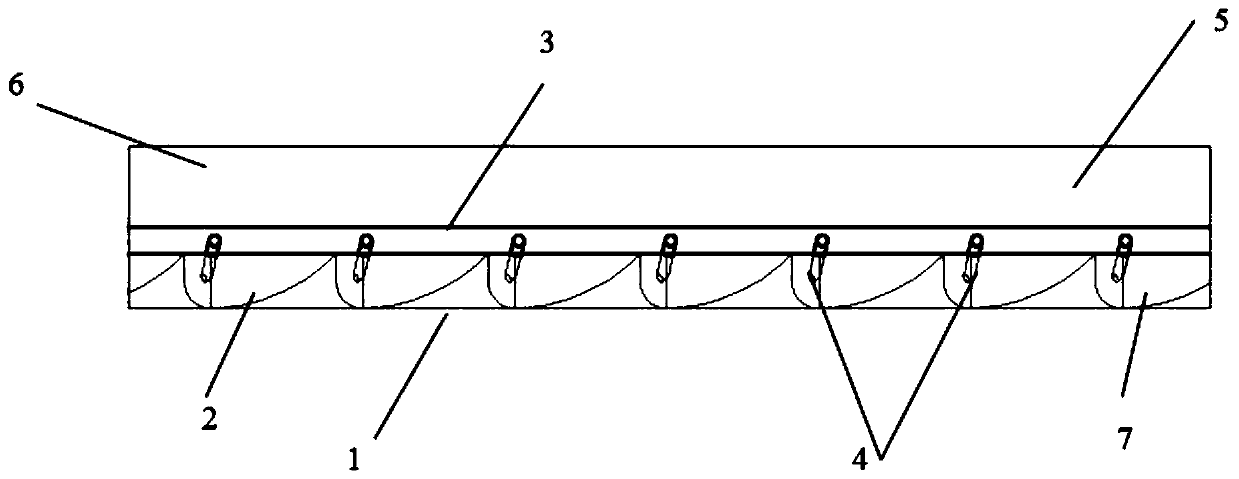

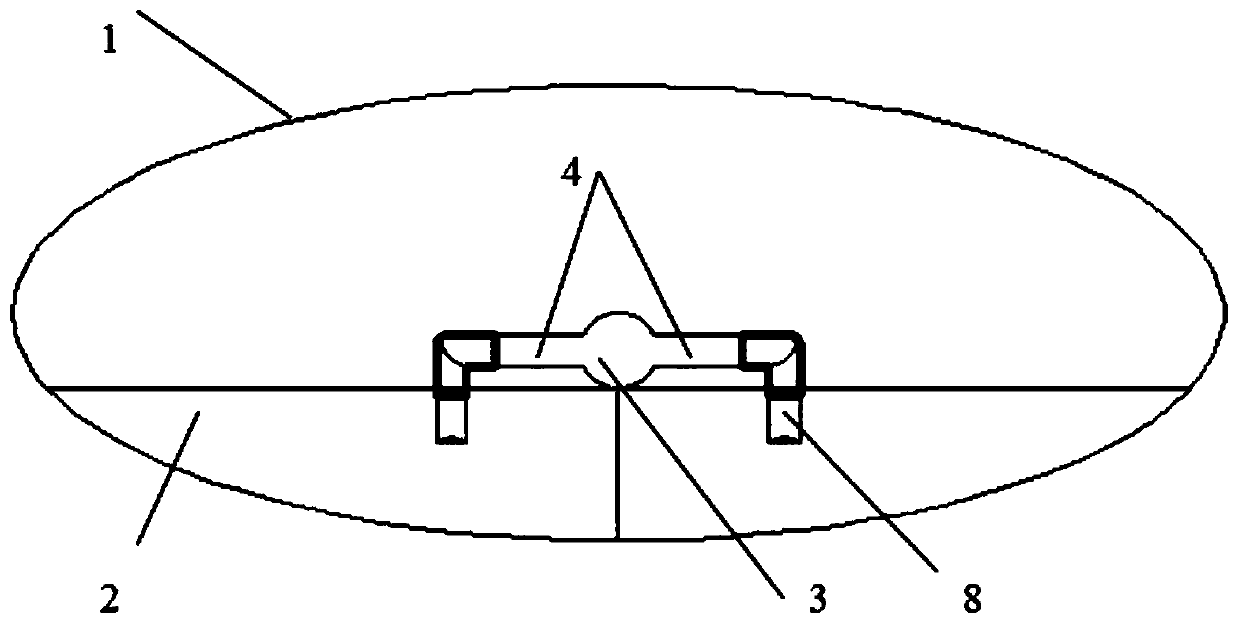

[0021] The present invention proposes an active washboard type fluidized bed pipeline for the transportation of powder materials, and its overall structure includes four parts: the outer wall of the pipeline, the wave washboard interlayer, the gas pipeline, and the recoil nozzle.

[0022] The pipe outer wall 1) in the structure is an elliptical flexible pipe structure, one end is a feed port 5), and one end is a discharge port 6);

[0023] The wavy washboard interlayer 2) in the structure is a structure with a symmetrical central axis, which is a series of round spoon-shaped wave structures 7), and the surface is coated with Teflon coating. The wavy washboard interlayer 2) separates the pipeline into two parts. The lower one is closed with a solid structure, on which is the powder material transport chamber, which is close to the central axis of the wave washboard compartment 2), and has a gas channel 3) running through it;

[0024] The gas pipeline 3) in the structure is a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com