Chemical agent adding method and device

A chemical agent, one-way technology, applied in the field of chemical agent adding method and device, can solve the problems of unfavorable industrial production and transportation of the device, insufficient response of the chemical agent addition, and high energy consumption of the motor pump, which is beneficial to industrial manufacturing and long-distance transportation. The effect of safe production and easy on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

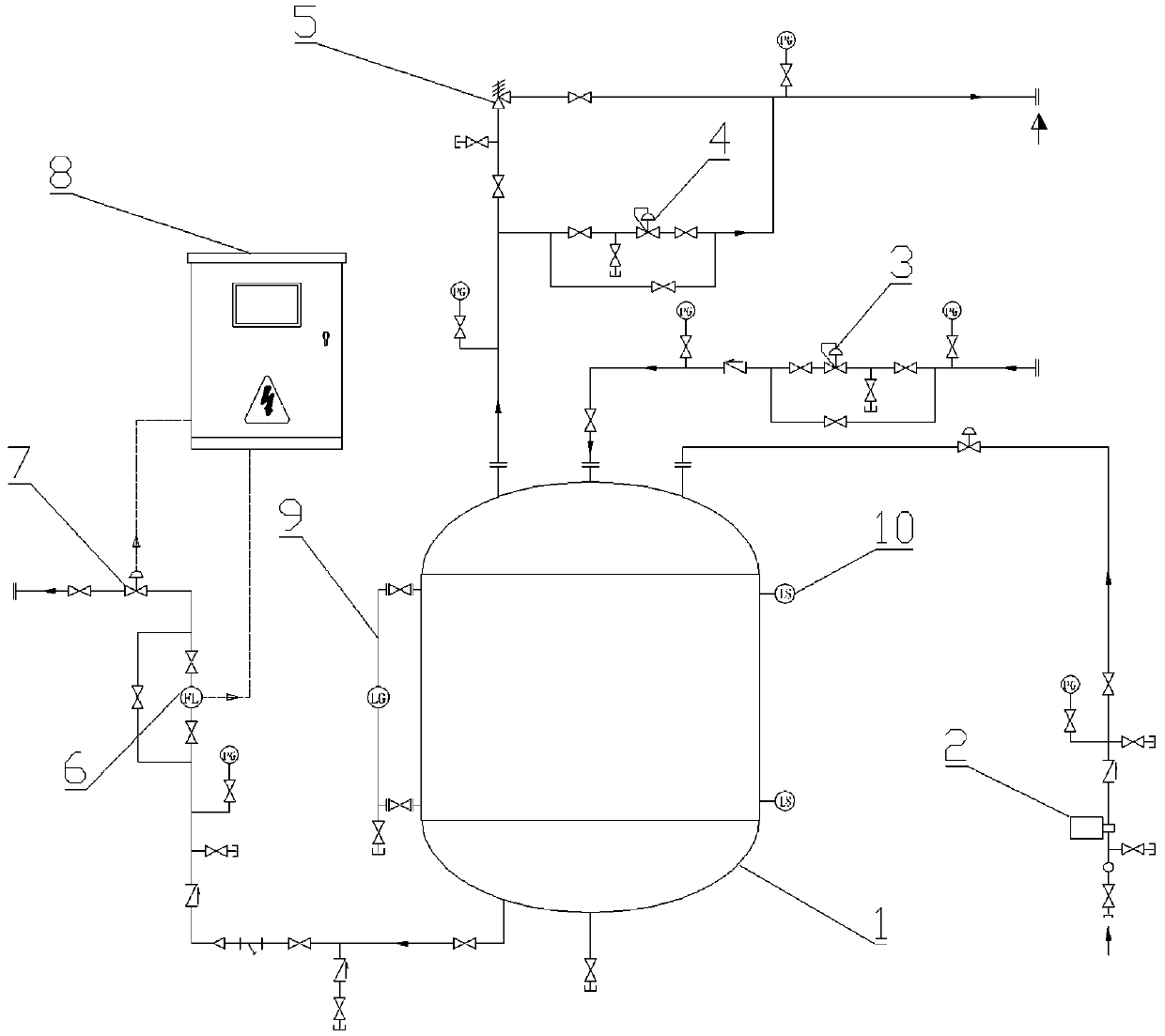

[0032] Such as figure 1 Shown, a kind of chemical agent adding method comprises the steps:

[0033] a. Keep the pressure in the storage container of the chemical agent at 1.0MPa-1.5MPa, the pressure comes from the constant pressure nitrogen gas from the public works, in addition, it is necessary to use the self-operated regulating valve group 4 of the sealing gas discharge pipeline to maintain the sealing gas discharge After the pipeline self-operated regulating valve group 4, that is, the pressure in the storage container of the chemical agent can be replenished to the set value when nitrogen is replenished;

[0034] b. When the chemical agent in the chemical agent storage container is insufficient, add chemical agent to the chemical agent storage container. When the chemical agent is replenished, the pressure in the chemical agent storage container may exceed the standard. At this time, cooperation is required. Use the self-operated regulating valve group 4 of the sealing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com