Novel liquid filling device

A technology for filling equipment and liquids. It is used in liquid distribution, transportation or transfer devices, special distribution devices, packaging, etc. It can solve the problems that affect the stable operation of the equipment, easily mix with gas, and simplify the pipeline layout. , The effect of reducing the amount of dissolved gas and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

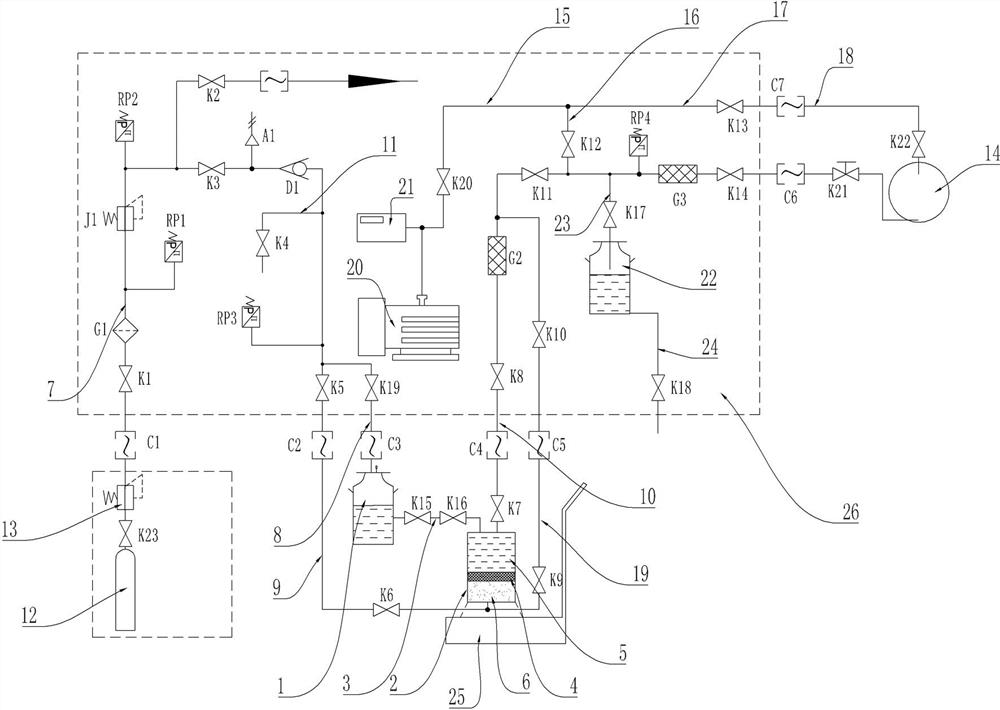

[0040] like figure 1 As shown, the new liquid filling equipment includes a liquid storage tank 1 and a squeeze tank 2. The liquid storage tank 1 and the squeeze tank 2 are connected through the liquid tank connecting pipeline 3, and the liquid tank connecting pipeline 3 is provided with a liquid inlet cut-off valve. , The liquid inlet cut-off valve is arranged between the liquid storage tank 1 and the squeeze tank 2 to control the on-off of the passage between the two. The liquid storage tank 1 is connected with an air filling pipeline. When injecting liquid into the squeeze tank 2, the liquid in the liquid storage tank 1 is pressed out by adding air and pressurizing the liquid storage tank 1. After the liquid injection is completed, close the inlet. Liquid shut-off valve. In this embodiment, there are two cut-off valves for liquid inlet, namely, the cut-off valve for liquid inlet K15 and the cut-off valve for liquid inlet K16. The two cut-off valves for liquid inlet can ensu...

specific Embodiment 2

[0086] The specific embodiment 2 of the novel liquid filling device of the present invention, the difference between the structure of the novel liquid filling device in this embodiment and the above specific embodiment 1 is that in this embodiment, when the piston is squeezed, it is directly injected into the extrusion chamber Gas, without vacuuming, at this time there is no need to set up a vacuuming pipeline for the extrusion chamber.

[0087] The specific embodiment 3 of the new liquid filling equipment of the present invention, the structure of the new liquid filling equipment in this embodiment differs from the above specific embodiment 1 only in that the vacuuming pipeline of the extrusion chamber is directly connected with the vacuum pump group.

[0088] Specific embodiment 4 of the novel liquid filling device of the present invention. The difference between the structure of the novel liquid filling device in this embodiment and the above specific embodiment 1 is that a ...

specific Embodiment 5

[0089] Embodiment 5 of the novel liquid filling equipment of the present invention. The structure of the novel liquid filling equipment in this embodiment differs from that of the above specific embodiment 1 only in that the electronic scale is set on the filling vehicle. In other embodiments, all pipelines can be arranged on the filling vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com