Test method used for overturning test of oil tank

A technology of fuel tank and turning table, which is applied in the direction of measuring the acceleration and deceleration rate of fluid and using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of laborious turning, low efficiency and inconvenience, and achieve accurate filling, The effect of improving efficiency and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

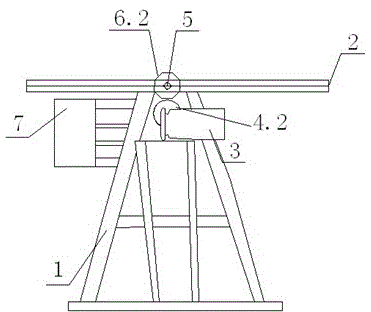

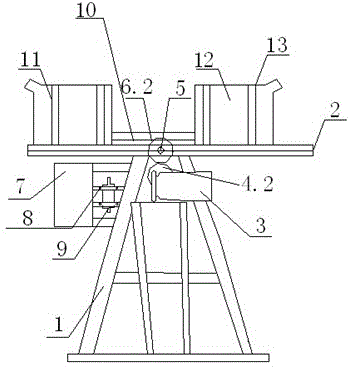

[0019] Below in conjunction with accompanying drawing, describe in further detail:

[0020] Such as figure 1 Shown is a schematic diagram of an overturning platform for gear transmission power used for tank overturning tests, including an overturning platform bracket 1, an overturning platform 2, and an asynchronous motor 3. The overturning platform 2 is connected to the overturning platform bracket 1 with a bearing 5, and the asynchronous The motor 3 is fixed on the turning platform 2, the output shaft of the asynchronous motor 3 is fixed to a driving gear 4.2, and the short shafts on both sides of the turning platform 2 are splined to fix a driven gear for transmission to make the turning platform turn over 6.2, the driving gear 4.2 and the driven gear 6.2 mesh with each other to form a gear transmission mechanism. The control cabinet 7 used to control the asynchronous motor 3 is provided on the overturning table support 1. The control cabinet 7 includes an electrical box ...

Embodiment 2

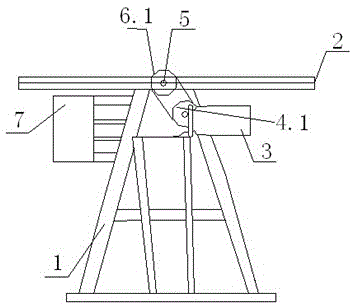

[0029] Below in conjunction with accompanying drawing, describe in further detail:

[0030] Such as image 3 What is shown is an inversion bench used for the inversion test of the fuel tank. The gear transmission mechanism in the first embodiment is replaced with a belt transmission mechanism, and a spline is fixed on the short shafts on both sides of the inversion platform 2 for transmission. The driven pulley 6.1 that makes the turning platform turn over, the driving pulley 4.1 and the driven pulley 6.1 are connected by a transmission belt to form a transmission mechanism to drive the turning platform 2 to turn over. In this embodiment, a 1.5kw AC asynchronous motor 3 is selected as the turning platform support The power source of 1, under the control of the frequency converter in the control cabinet 7, the speed of the asynchronous motor 4 is controlled according to the needs, and the power is transmitted to the driven pulley 6.1 through the belt transmission mechanism t...

Embodiment 3

[0033]Below in conjunction with accompanying drawing, describe in further detail:

[0034] Such as Figure 5 Shown is a kind of inversion stand used for fuel tank inversion test, including inversion platform support 1, inversion platform 2, worm gear reducer 14 and asynchronous motor 3, inversion platform 2 is connected on inversion platform support 1 with bearing 5, Fix the worm gear reducer 14 on the overturning table support 1 with bolts, the output shaft of the asynchronous motor 3 is connected with the input shaft of the worm gear reducer 14 through the bushing, and the short shafts on both sides of the overturning platform 2 are fixed with splines One is used to drive the turning gear 6 that turns the turning platform overturned. The output shaft gear 4 of the worm gear reducer 14 is fixed on the output shaft of the worm gear reducer 14 and meshes with the turning gear 6. The turning platform support 1 is provided with a The control cabinet 7 that controls the async...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com