Semi-autogenous mill steel ball hoisting and charging device capable of effectively preventing steel balls from falling

A semi-autogenous grinding machine and filling device technology, applied in the field of mining machinery and mineral processing machinery, can solve the problems of affecting the economic benefits of enterprises, increasing production costs, and equipment falling on personnel, etc., to achieve simple structure, reduce production costs, and avoid smashing The effect of bad equipment and hitting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the teaching of the present invention falls within the protection scope of the present invention.

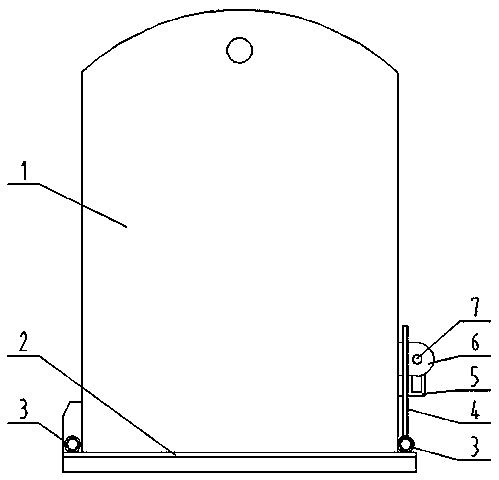

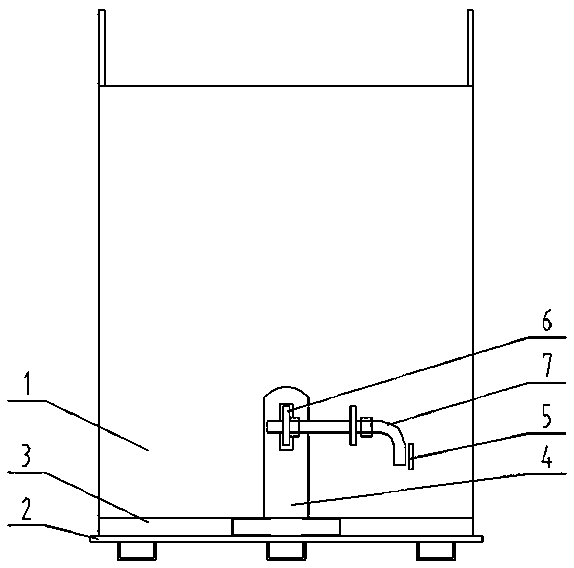

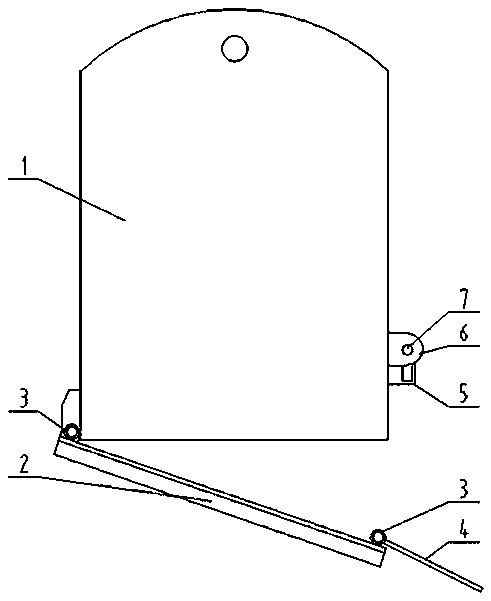

[0013] Such as Figure 1~4 As shown, the present invention includes a bucket body 1, a bottom plate 2, a hinge 3, a lock catch 4, a baffle plate 5, a lock catch seat 6, and a lock pin 7. The right side of the bucket body 1 is provided with a baffle plate near the lower port. 5 and the lock seat 6; the lock pin 7 is set on the lock seat 6; the upper end of the front and back of the bucket body 1 is respectively provided with lifting holes; the bottom port of the bucket body 1 is provided with Bottom plate 2; a hinge 3 is set between the left end of the bottom plate 2 and the bucket body 1; a lock 4 is set at the right end of the bottom plate 2; a hinge 3 is set between the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com