Novel compressed hydrogen filling machine for car

A technology for compressing hydrogen and refueling machines, which is applied in motor vehicles, road vehicles, mechanical equipment, etc. It can solve problems such as hidden dangers, rising temperature, and monotonous operation interface, so as to reduce construction costs, reduce floor space, and prevent flow rate. too fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

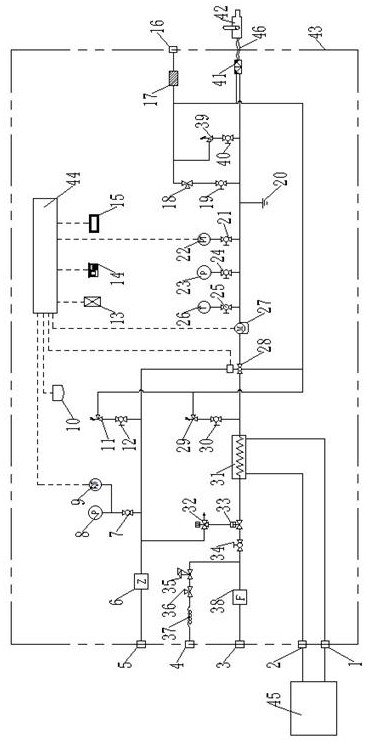

[0022] Describe technical scheme of the present invention in detail in conjunction with accompanying drawing, as figure 1 As shown, a novel compressed hydrogen refueling machine for automobiles comprises a casing 43, a PLC control system 44 arranged on the casing 43, a quick-loading chuck connector I1, a quick-loading chuck connector II2, and a hydrogen input interface 3. Hydrogen gas sampling port 4, drive gas input port 5, gas vent port 16, hydrogenation gun pipe telescopic port and the piping system set in the box 43, hydrogen gas input port 3 is sequentially connected with the filter 38 through the hydrogenation pipeline , high-pressure ball valve III 34, pneumatic ball valve 33, electronic pressure regulating valve 28, mass flow meter 27 and pull-off device 41 are connected, and the pull-off device 41 is connected with hydrogenation gun 42 through connecting hose II 46, and pneumatic ball valve 33 is connected with electronic The partial hydrogenation pipeline between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com