Lubricating grease injecting device and application of lubricating grease injecting device in elevator head sheave

A technology of lubricating grease and oiler, which is applied in lubricating parts, manually supplying lubricant, lubricating the engine, etc. It can solve the problems of operator danger, difficulty in adding grease, and hidden dangers of long-term safe operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

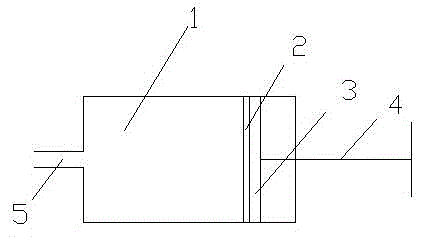

[0016] A lubricating grease injector, comprising an oil outlet 5, the oil outlet 5 is arranged on a closed port of a steel pipe and communicates with the inner cavity, the inner wall of the steel pipe 1 is provided with threads, and there is a thread in the steel pipe 1 that is tightly connected to the inner wall of the steel pipe. The matching circular rubber plate 2 is connected on one side diameter surface of a wire circular steel plate 3 threadedly matched with the inner wall of the steel pipe, and the center of the other side diameter surface of the wire circular steel plate 3 is fixedly connected with a protruding cylinder and the other A radial handle bar 4 with an open end, marked with a scale indicator; the inner cavity of the steel pipe between the circular rubber plate 2 and the closed port is filled with lubricating grease.

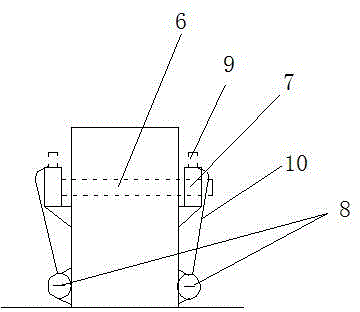

[0017] An application of a lubricating grease oiler on the sky wheel of the hoist, characterized in that the oil outlet 5 is connected to an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com