Energy-saving and environment-friendly chemical waste treatment equipment

A garbage disposal equipment, energy-saving and environment-friendly technology, applied in the direction of chemical/physical processes, chemical instruments and methods, mixers, etc., can solve the problems of liquid medicine waste, low work efficiency, time-consuming and labor-intensive, etc., to improve work efficiency and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

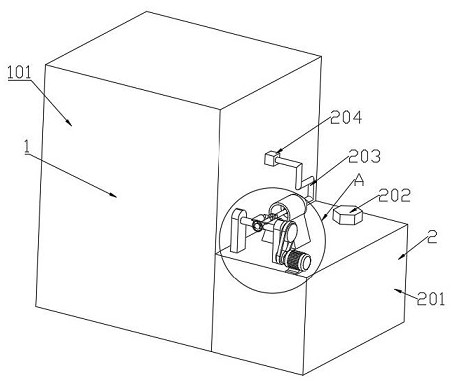

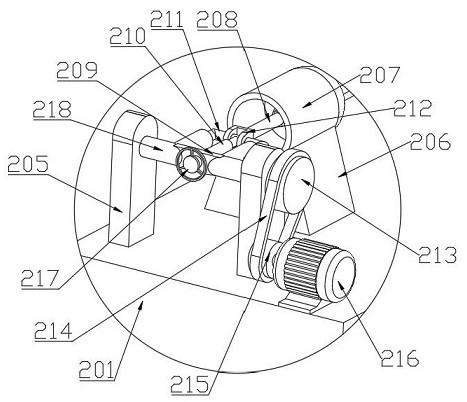

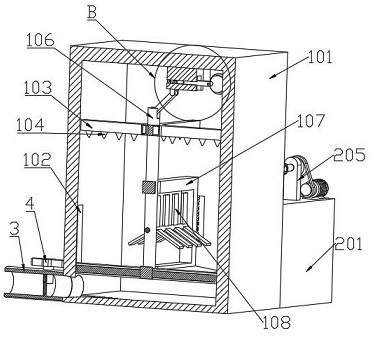

[0042] See Figure 1 ~ 12 In the embodiment of the present invention, an energy-saving environmentally-friendly chemical waste treatment apparatus includes a stirring device 1 and a dielectric device 2, and the stirring device 1 includes a stirring box 101, and a fixed frame 103 is fixedly attached to the mixing frame 103, and the fixing frame 103 The inner slide is slidably connected to the moving rod 106, the moving rod 106 is fixed to the fixed frame 107, and the fixed frame 107 is rotatably coupled to the shaft 123, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com