Shale gas horizontal well casing-fixation-in-casing refracturing method

A technology for refracturing and horizontal wells, which is applied in the field of shale gas horizontal well casing casing refracturing, which can solve problems such as poor stimulation effects, achieve strong applicability, ensure safety and reliability, and improve liquid efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is further described in detail through specific implementation methods:

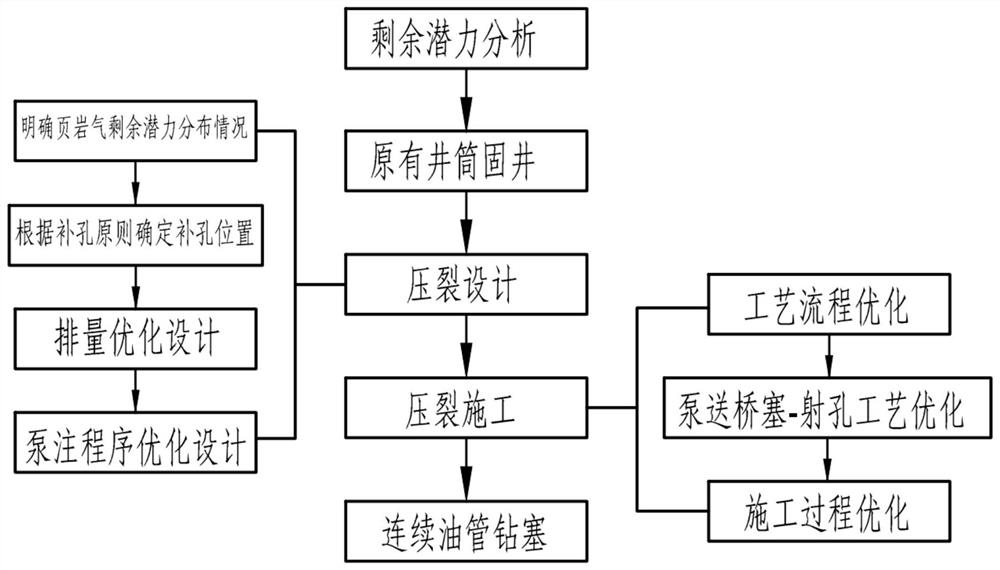

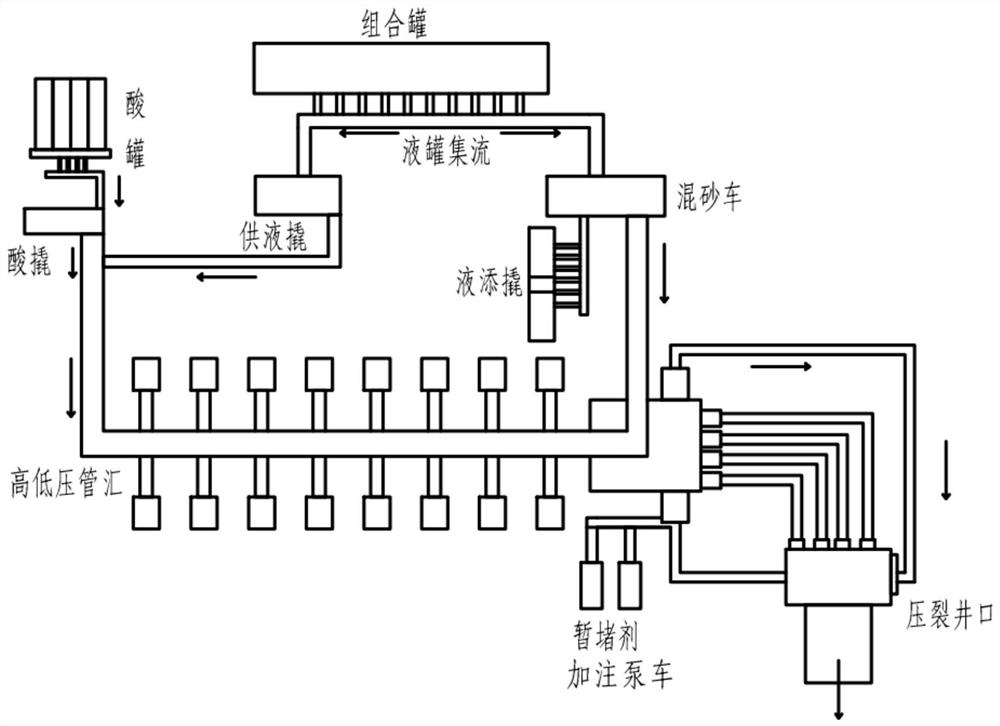

[0033] The embodiment is basically as attached figure 1 with attached figure 2 Shown: a shale gas horizontal well casing casing refracturing method, including:

[0034] Step 1. Combined with the gas production profile test to analyze the remaining potential after refracturing:

[0035] 1) The gas production profile test was carried out under the two production systems of 60,000 m3 / day and 120,000 m3 / day, and the gas production contribution percentage of each cluster in the initial fracturing in the original wellbore was obtained. To judge the consistency of gas production contribution under the two production systems, the gas production contribution percentage of each fracturing cluster closest to the average value was selected as the reference data.

[0036] 2) Combined with the geological characteristics of the gas reservoir (such as gas content, physical properties, etc.), est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com