Industrial intelligent lubricating system and control method

A lubricating system and industrial technology, used in lubricating parts, engine lubrication, signal processing, etc., can solve problems such as random operation, unfavorable equipment operation, and excessive lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

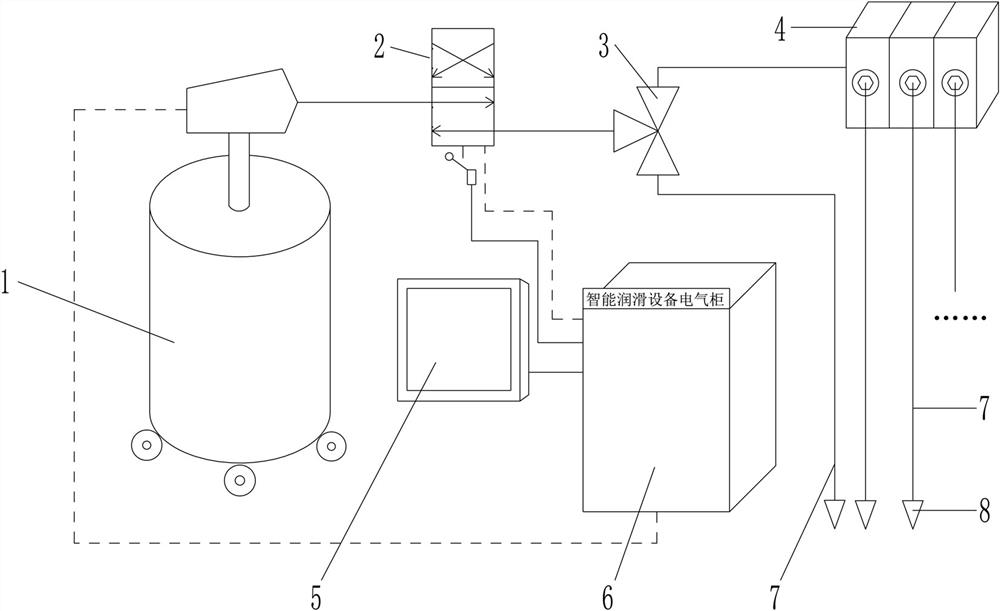

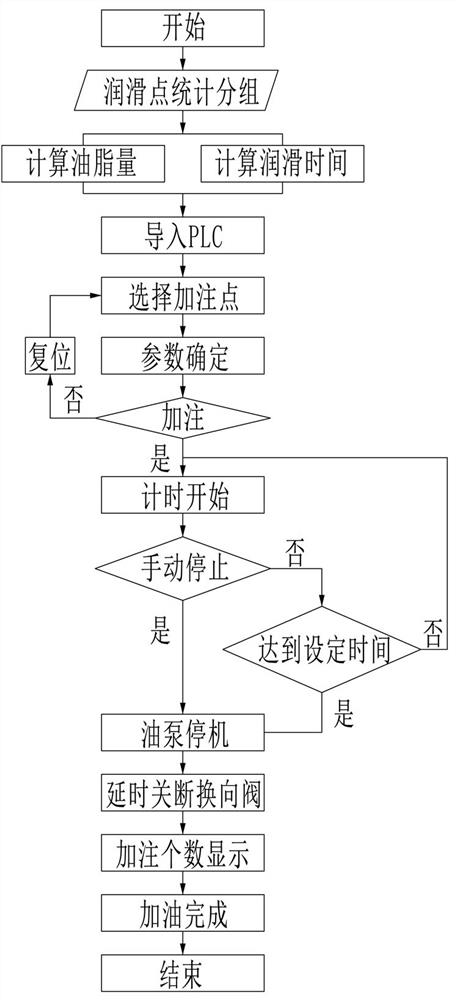

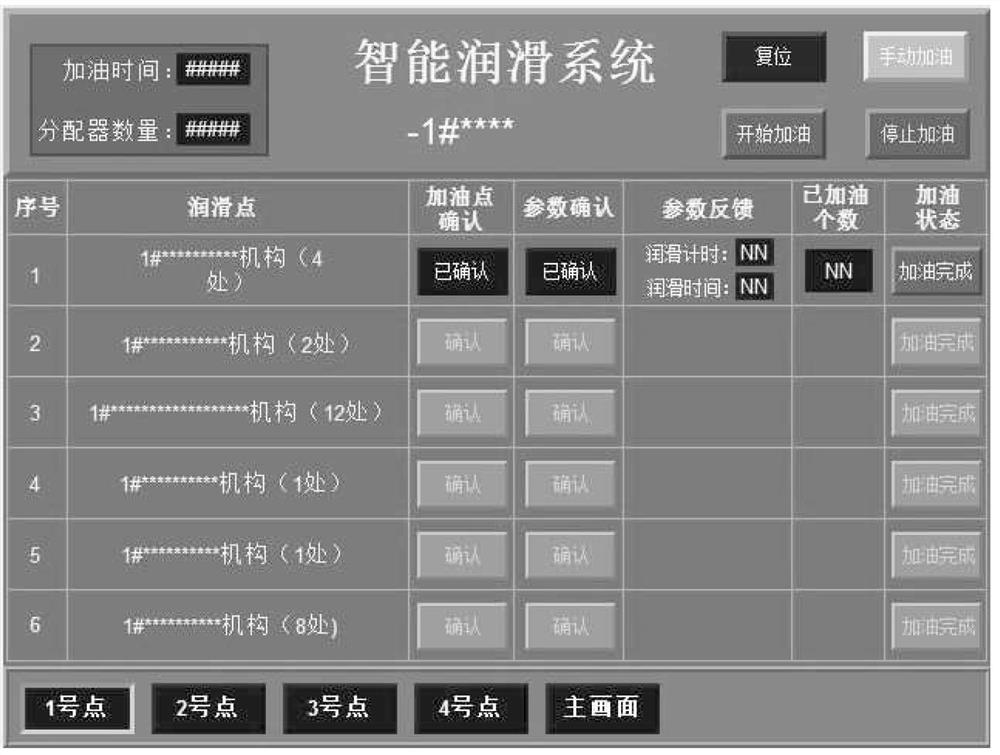

[0033] like Figure 1~Figure 3 Among them, an industrial intelligent lubrication system, which includes a refueling device 1, a grease reversing valve 2, a three-way switching valve 3, a grease distributor 4, an industrial touch screen 5 and an electrical panel cabinet 6; The refueling equipment 1 is in communication with the three-way switching valve 3 , the grease distributor 4 is in communication with one of the output ends of the three-way switching valve 3 , and the electrical panel 6 is electrically connected with the refueling equipment 1 , the grease reversing valve 2 and the industrial touch screen 5 . When in use, the control system controls the opening and closing of the grease filling circuit, fixed-point, quantitative, and regular filling of grease to the lubricating points of the equipment mechanism, centralized control, to avoid errors in grease filling records, omissions or duplication of filling, which is conducive to improving the mechanical operation of large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com