Grease filling gun

A butter filling and butter technology, which is applied to lubricating oil control valves, engine components, lubricating parts, etc., can solve problems such as hidden dangers of mechanical equipment, damage to the grease gun, easy generation of air resistance, etc., to prevent damage to the oil gun, reduce Wasteful, portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

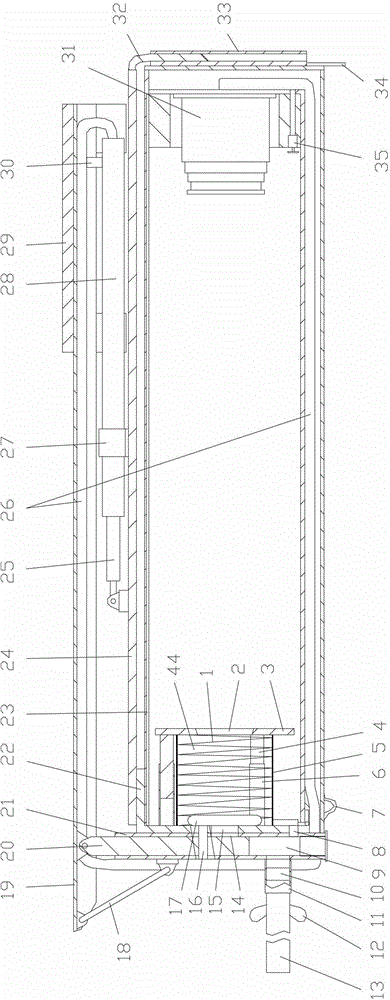

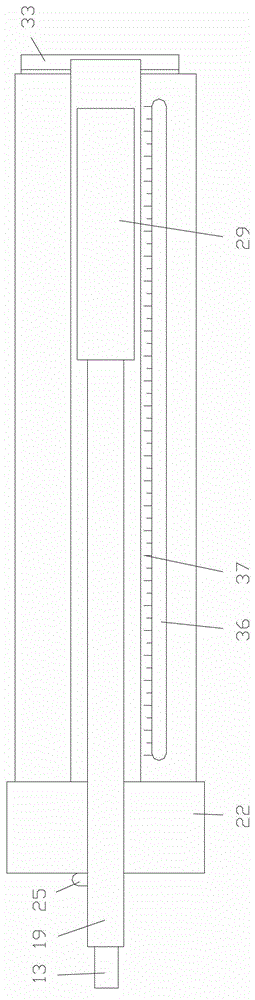

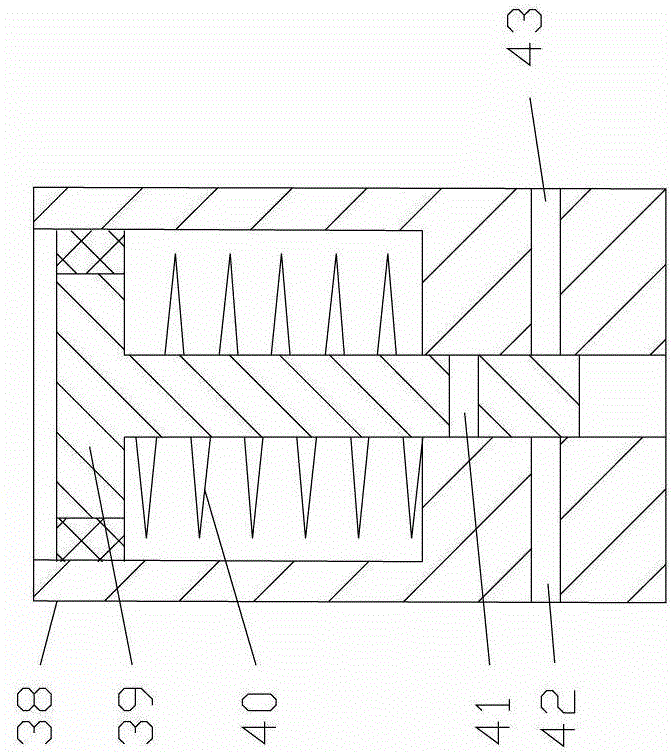

[0010] Such as figure 1 , 2 As shown, the upper end of the end cover 22 is fixed to the support plate 24; the left end of the end cover 22 is hinged to the oil pump 21, and the lower end of the oil pump 21 has a nozzle 11, and the nozzle 11 is in sealing communication with the pressure oil chamber 9 of the oil pump. The valve 10, the gun nozzle 11 is threaded to fix the oiling rod 13, the upper end of the oil pump piston 20 of the oil pump 21 is hinged with the lever 19, the left end of the lever 19 is hinged with the oil pump 21 through the pull rod 18, and the right end of the lever 19 is fixed with the gas cylinder 28 through the handle cover 29 , the left end of the cylinder piston 25 of the cylinder 28 is hinged with the support plate 24, and the lever 19 is lifted up and down through the handle cover 29, and the oil pump 21 and the cylinder 28 can be controlled simultaneously; the right end of the end cover 22 has a sleeve positioning groove, and the sleeve The left end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com