Waggle test storage tank liquid level measuring system

A technology for liquid level measurement and storage tank, which is applied in the field of liquid level measurement system of shaking test storage tank, can solve the problems of long time consumption, complicated pipeline disassembly and assembly, large accuracy error, etc., so as to reduce the negative impact and reduce the Small artificial strength, the effect of reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

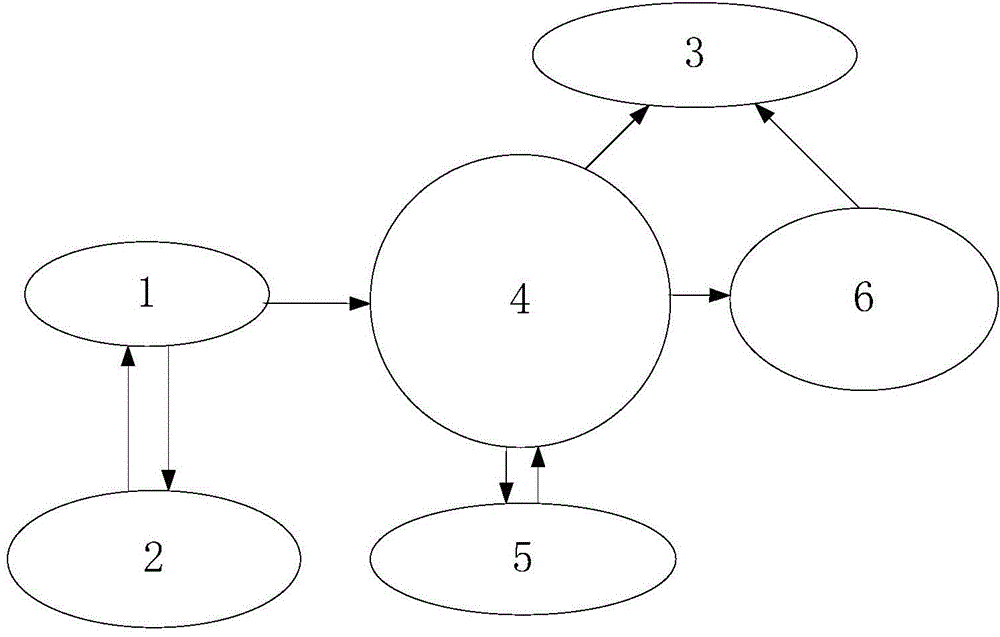

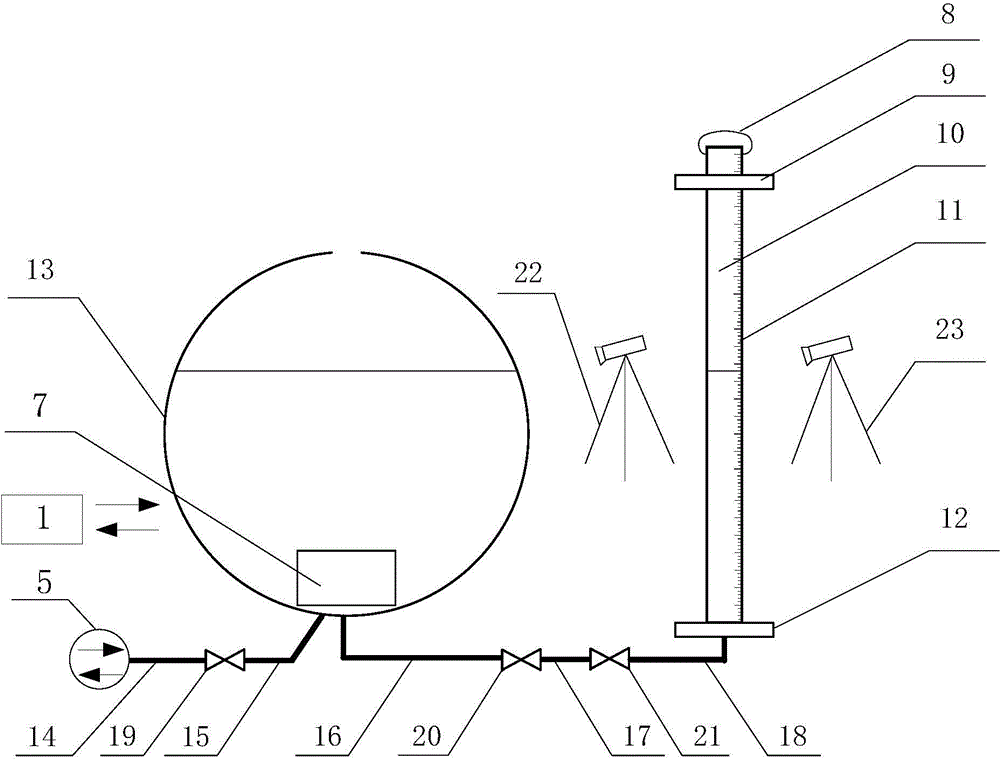

[0033] A sloshing test storage tank liquid level measurement system according to the present invention is applied to the storage tank liquid sloshing test. The test device is composed of six functional units, namely: sloshing unit 1, control acquisition unit 2, video monitoring unit 3, test Tank unit 4 , filling and draining unit 5 , liquid level measuring unit 6 . works like figure 1 As shown, the control acquisition unit 2 controls the shaking unit 1 to generate a shaking force that meets the test conditions, and collects the actual shaking test data parameters of the shaking unit 1. The shaking unit 1 causes the test storage tank unit 4 to generate corresponding shaking, and the excretion unit 5 is filled. Filling or draining the propellant simulation liquid for the test tank unit 4, the liquid level measurement unit 6 is used to accurately measure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com