Modular combined firework paper mold filling equipment

A technology of combining fireworks and loading equipment, applied in offensive equipment, pyrotechnics, weapon types, etc., can solve the problems of labor-consuming and time-consuming, difficult to guarantee product quality, low production efficiency, etc., to achieve easy maintenance and replacement, and high production efficiency. 、Easy to install and dismantle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be described in more detail with reference to the drawings and specific embodiments.

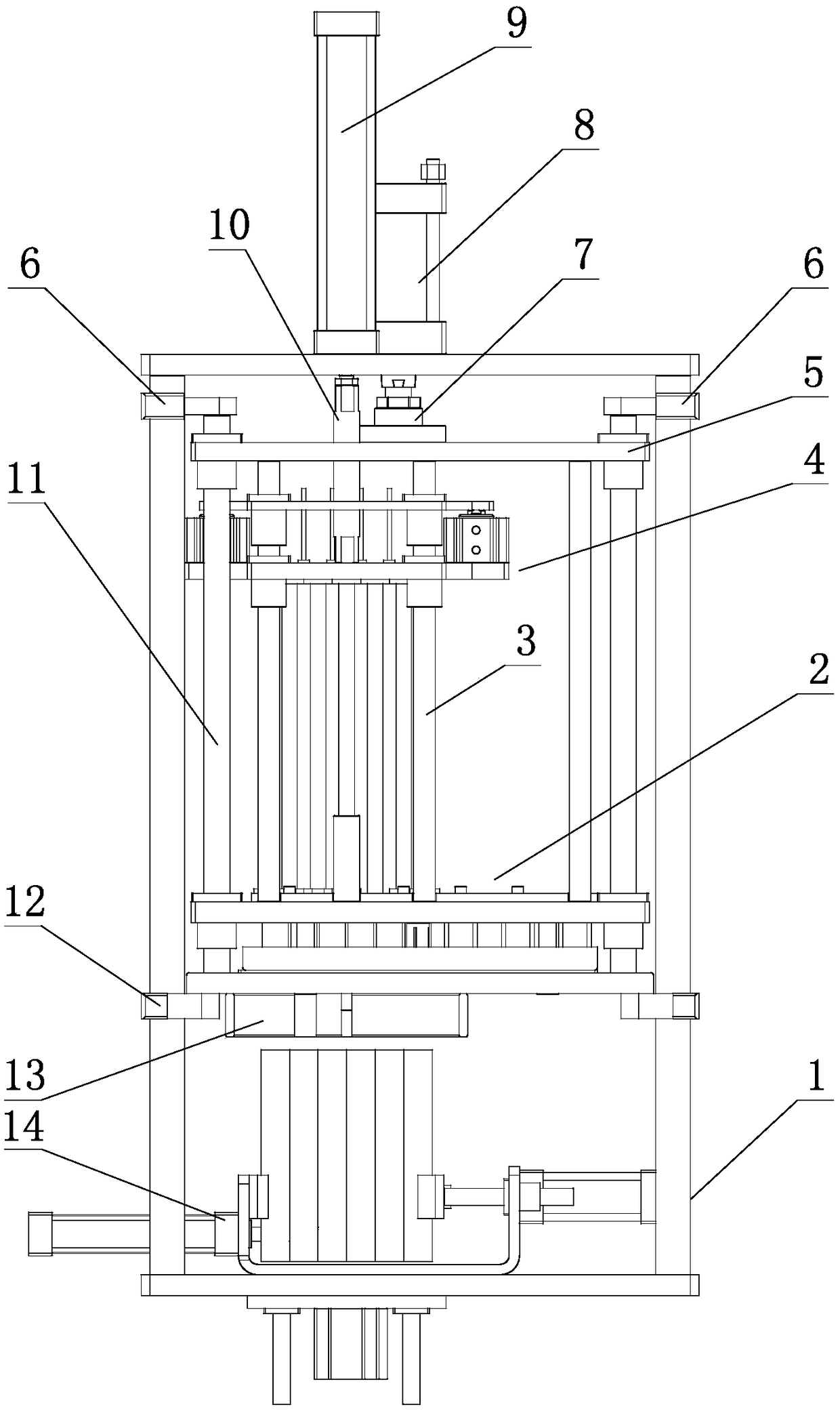

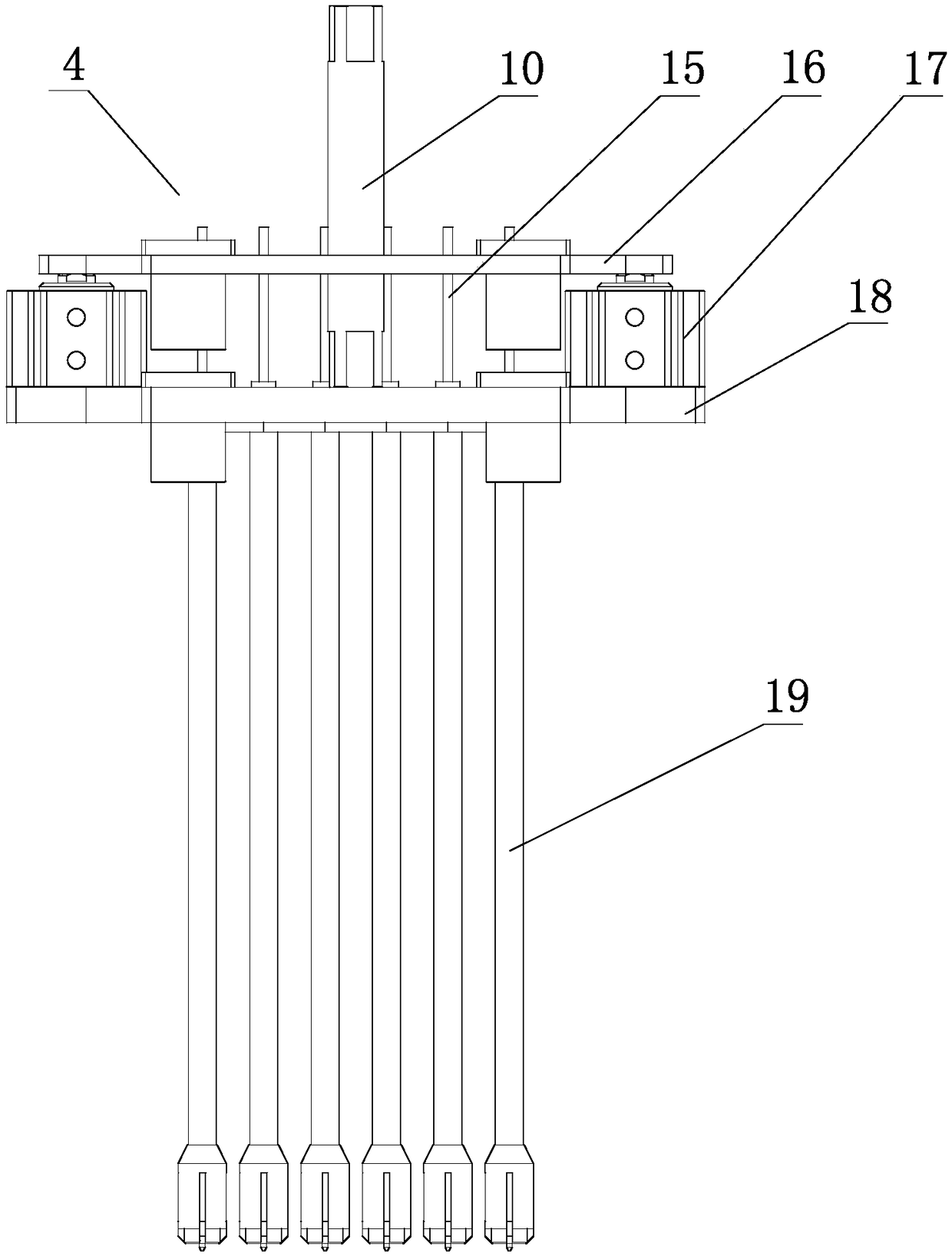

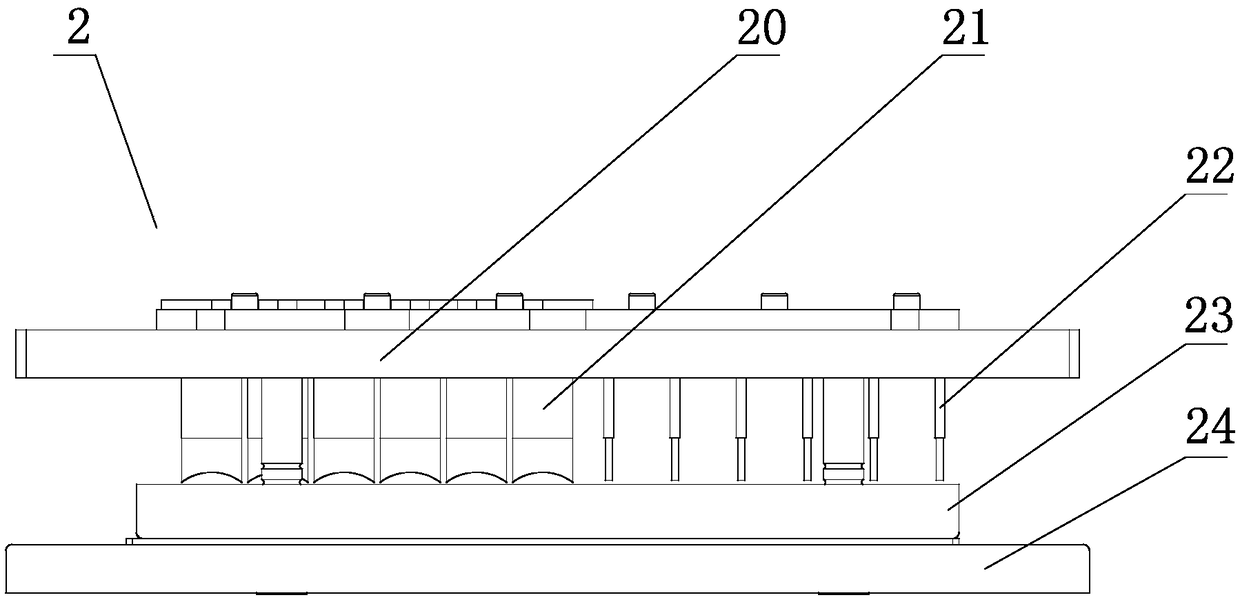

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, its composition consists of frame 1, paper forming component 2, fixed column 3, filling and stamping assembly 4, paper forming pressure plate 5, detachable connecting plate I6, detachable connecting seat 7, and paper forming drive mechanism 8 , Loading stamping drive mechanism 9, detachable connecting plate III10, auxiliary column 11, detachable connecting plate II12, filling mold 13, combined cylinder positioning mechanism 14, core rod 15, core rod fixing plate 16, detachment driving mechanism 17, brazing Rod fixing plate 18, stamping drill rod 19, cutter hole needle fixing plate 20, forming cutter 21, hole needle 22, guide plate 23, bottom plate 24, guide positioning hole 25, positioning rod 26, fasteners and connecting components, etc. Assembled.

[0022] The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com