Equipment for filling small box with middle box and process method of equipment

A boxing and equipment technology, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems that the cartoning machine cannot be realized, the labor intensity of the workers is high, and the production capacity of the enterprise is affected, so as to facilitate large-scale production and save labor costs , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

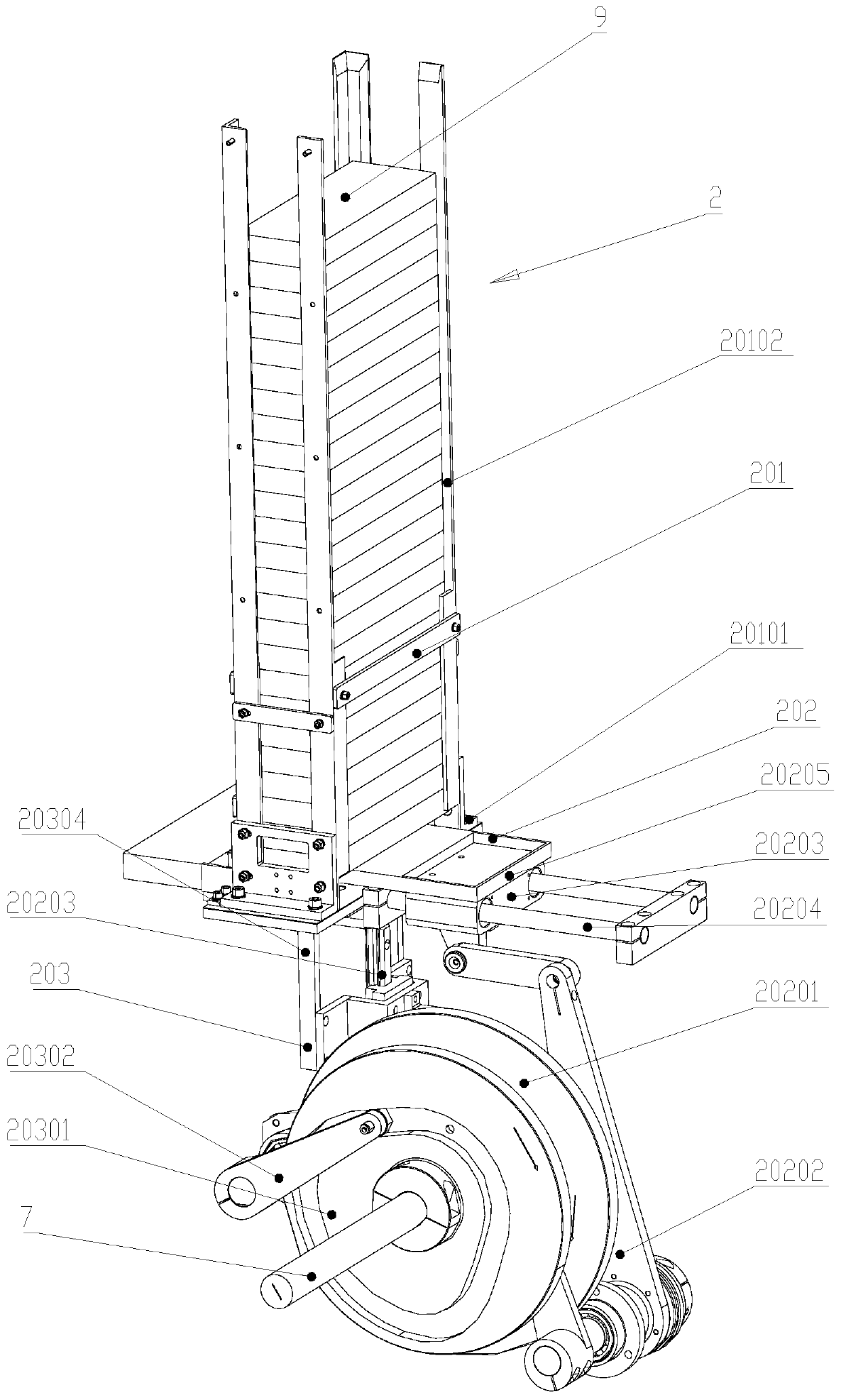

[0052] Embodiment one: if Figure 6 Shown, a kind of small box of the present invention fills the equipment of middle box.

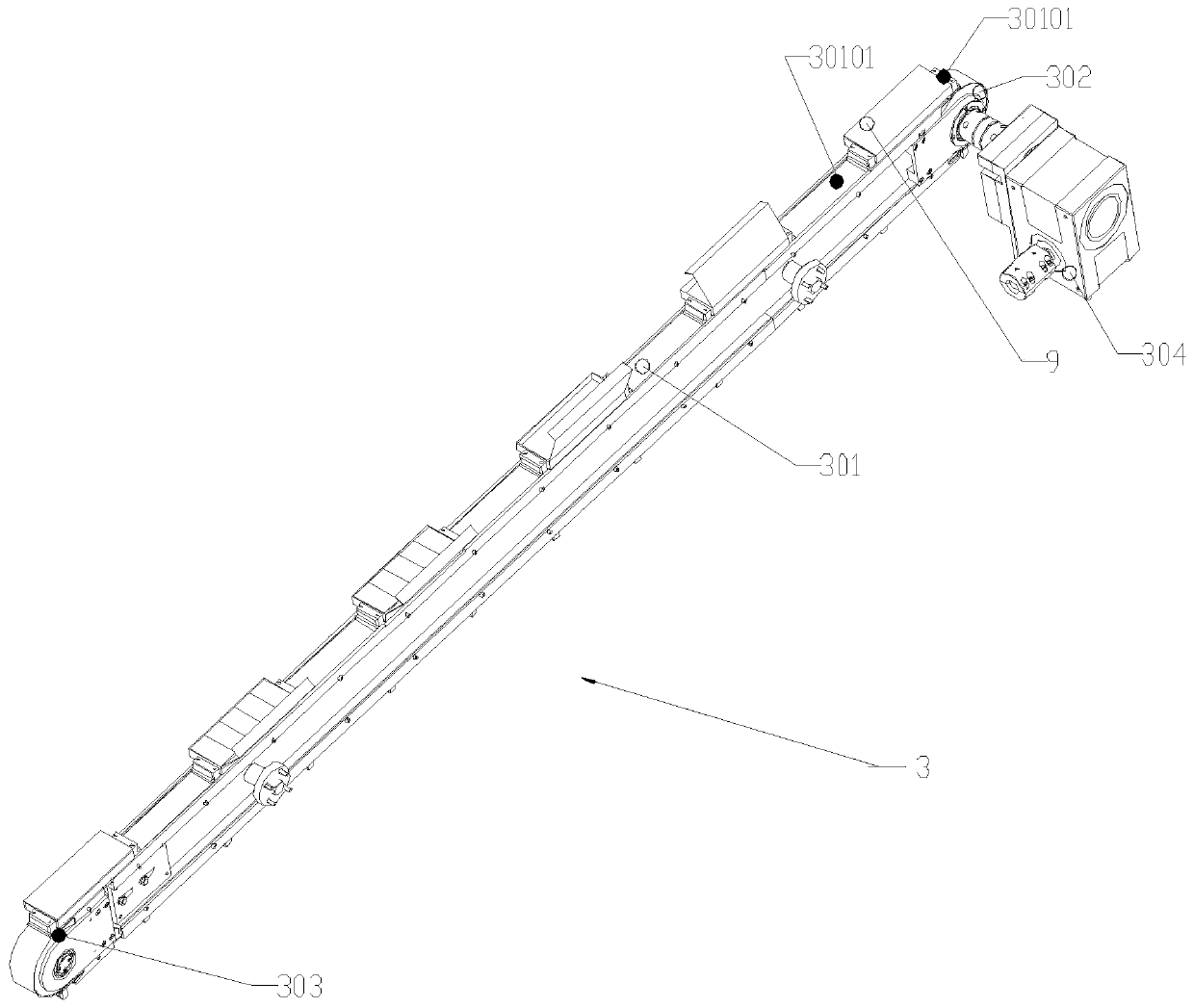

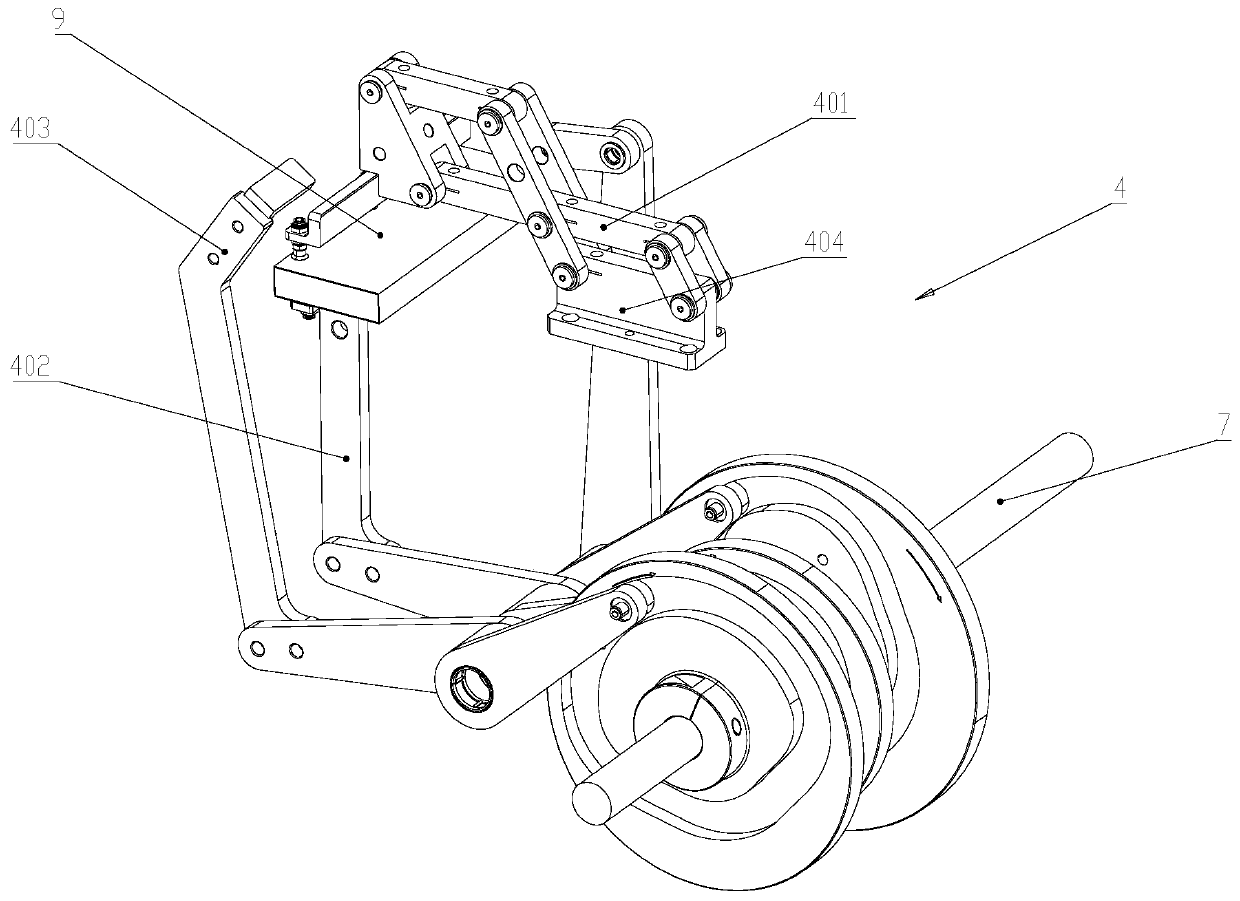

[0053] The equipment for filling the middle box with the small box mainly includes a box unloading device 2, a box conveying device 3, a box opening device 4, a box filling device 5, and a lid closing device 6. The above five devices share a main drive shaft 7 and are installed on the same rack 1.

[0054] The equipment for filling the small box into the middle box can automatically and continuously perform all the operations of filling the cigarette packs into the barrel.

Embodiment 2

[0055] Embodiment two: the process method of filling the middle box in the small box of the present invention comprises the following steps:

[0056] In the first step, the cam divider 304 of the cassette conveying device 3 converts the continuous motion of the cassette conveying timing belt assembly 301 into intermittent motion, and at the moment when the cassette conveying synchronous belt assembly 301 stops, the box pusher of the cassette lowering device 2 The cam 20201 drives more than one box-pushing link 20202 hinged to each other, through the box-pushing linear bearing assembly 20203, the box-pushing guide rod 20204, and then drives the box-pushing plate 20205 moving in the horizontal direction, and a box 9 is moved from the cigarette storehouse 201 Push out, and then, the box-connecting cam 20301 drives one or more box-connecting connecting rods 20302 that are hinged to each other, passes through the box-connecting linear guide rail 20303, and then drives the box-connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com