Tailing slurry recycling filling system and technology

A tailings and filling station technology, which is applied in the fields of fillings, raw material supply devices for sale, mining equipment, etc., can solve the problems of inconvenient tailings transportation, insufficient tailings sources, and inability to goaf, etc., and is applicable to a wide range of areas. , The effect of ensuring the filling quality and improving the strength of the filling body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

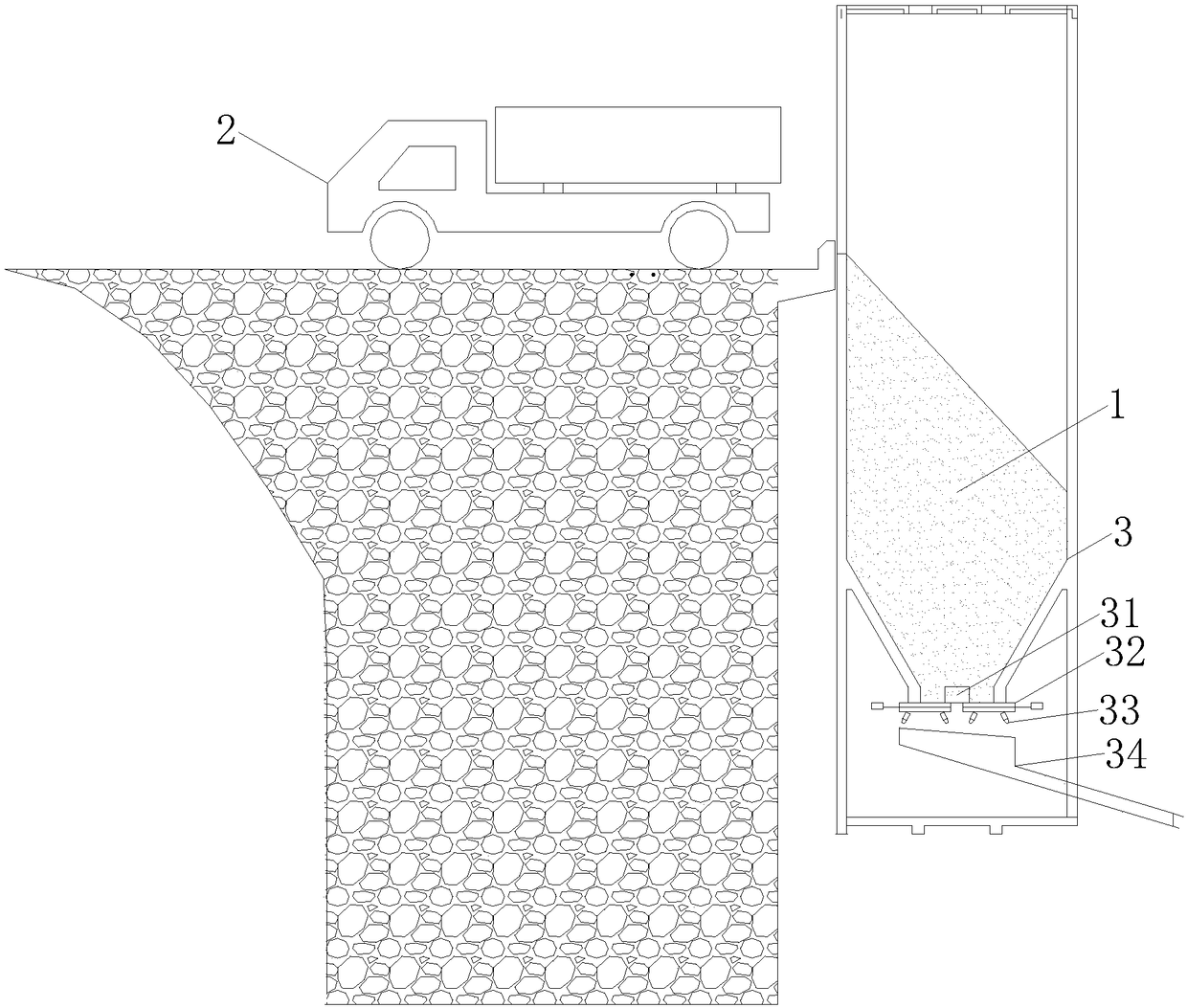

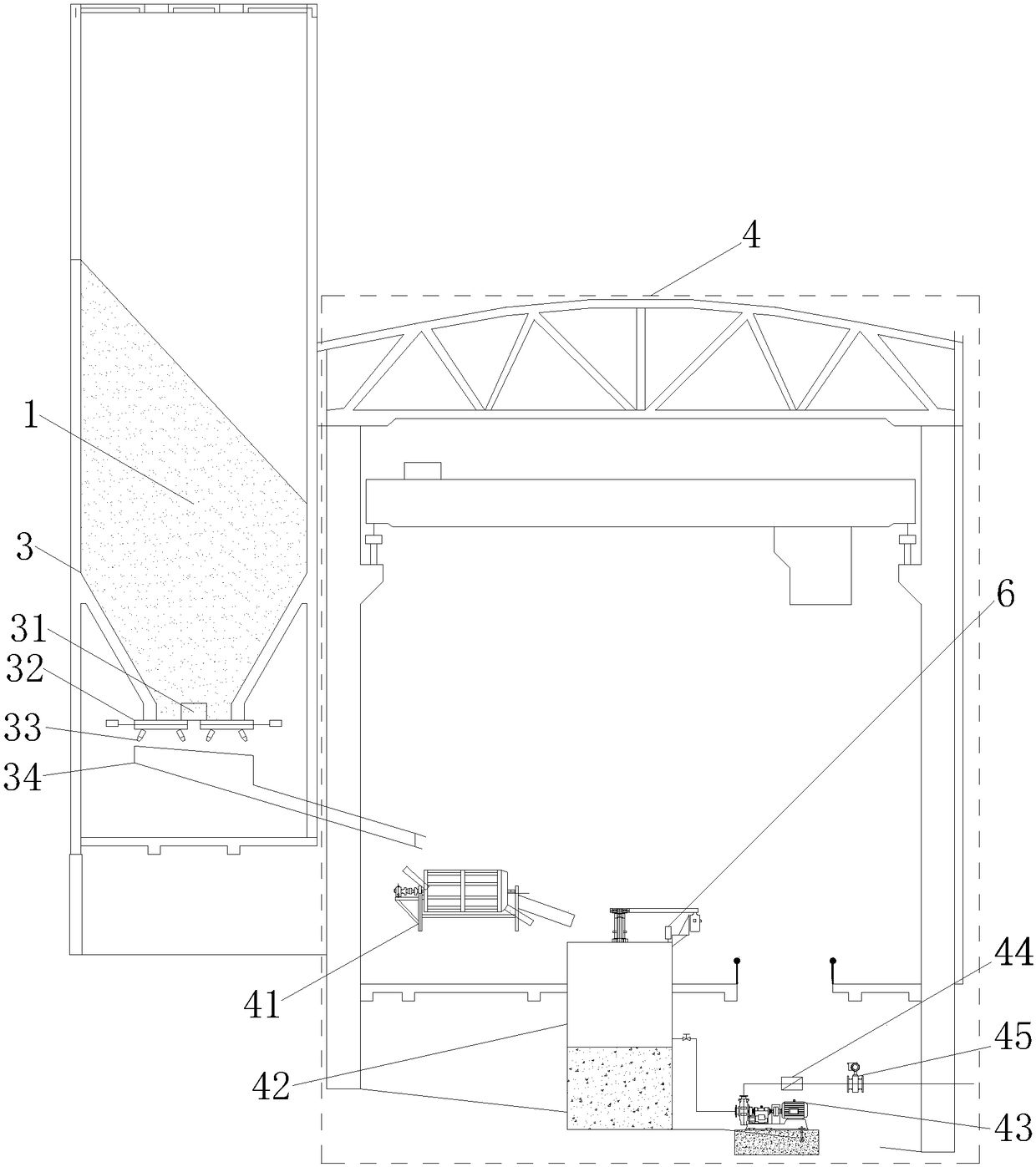

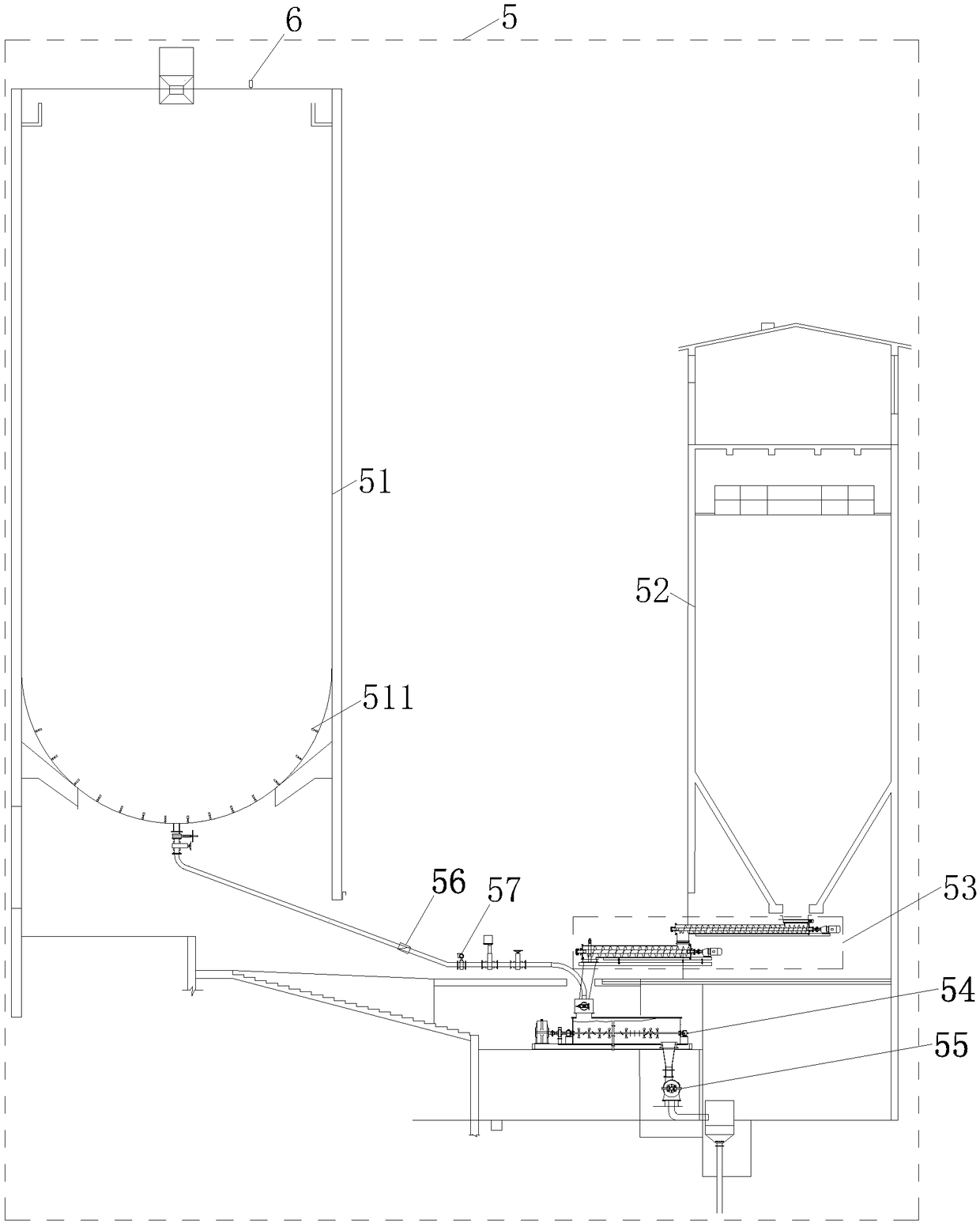

[0036] figure 1 It is a schematic diagram of the transport vehicle transporting the high-concentration tailings filter cake to the filter cake storage bin according to the preferred embodiment of the present invention; figure 2 It is a schematic diagram of the filter cake storage bin and the tailings re-slurry device of the preferred embodiment of the present invention forming tailings slurry from the high-concentration tailings filter cake; image 3 It is a schematic diagram of the filling slurry preparation device of the preferred embodiment of the present invention preparing tailing mortar into filling slurry; Figure 4 It is a schematic diagram of a screw weighing feeder in a preferred e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com