Pedal effort detector

A detector and pedal force technology, applied in the field of brake pedal force detection, can solve the problems of many human errors, inability to quantify pedal stroke distance, inaccurate test results, etc., so as to improve vehicle safety performance, ensure filling quality, The effect of accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

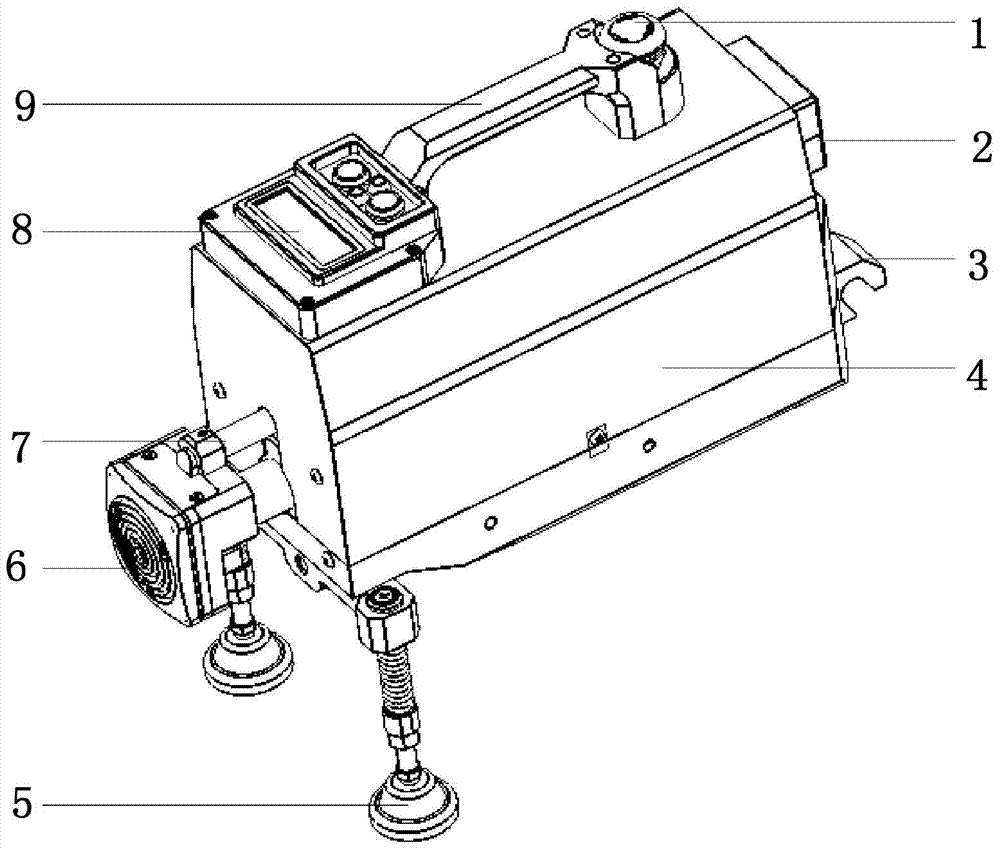

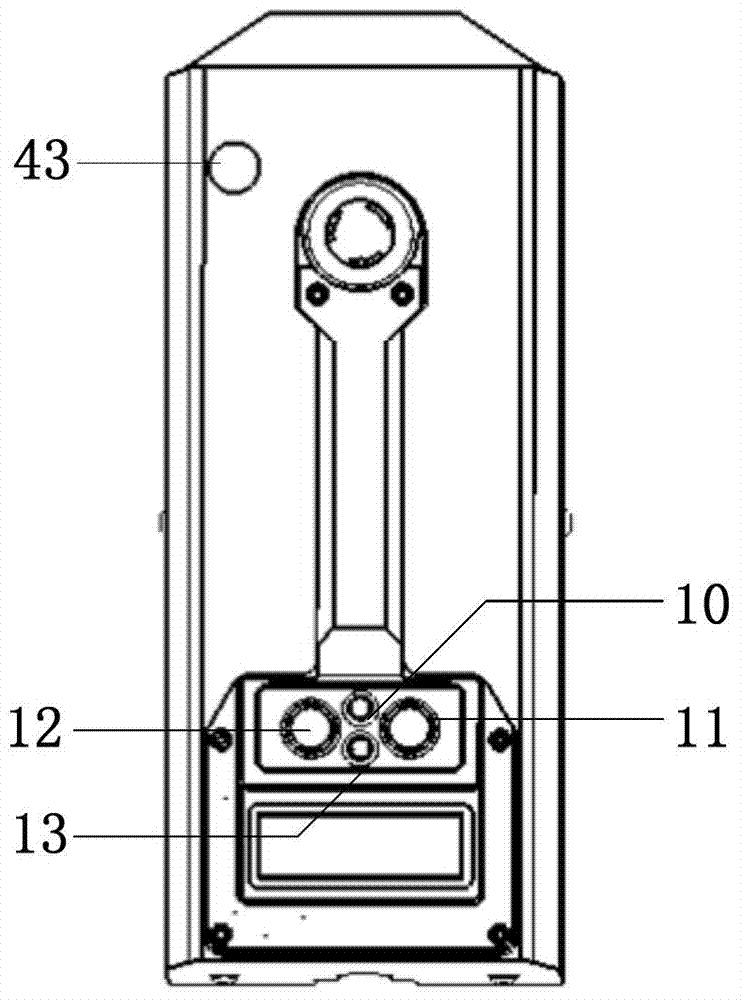

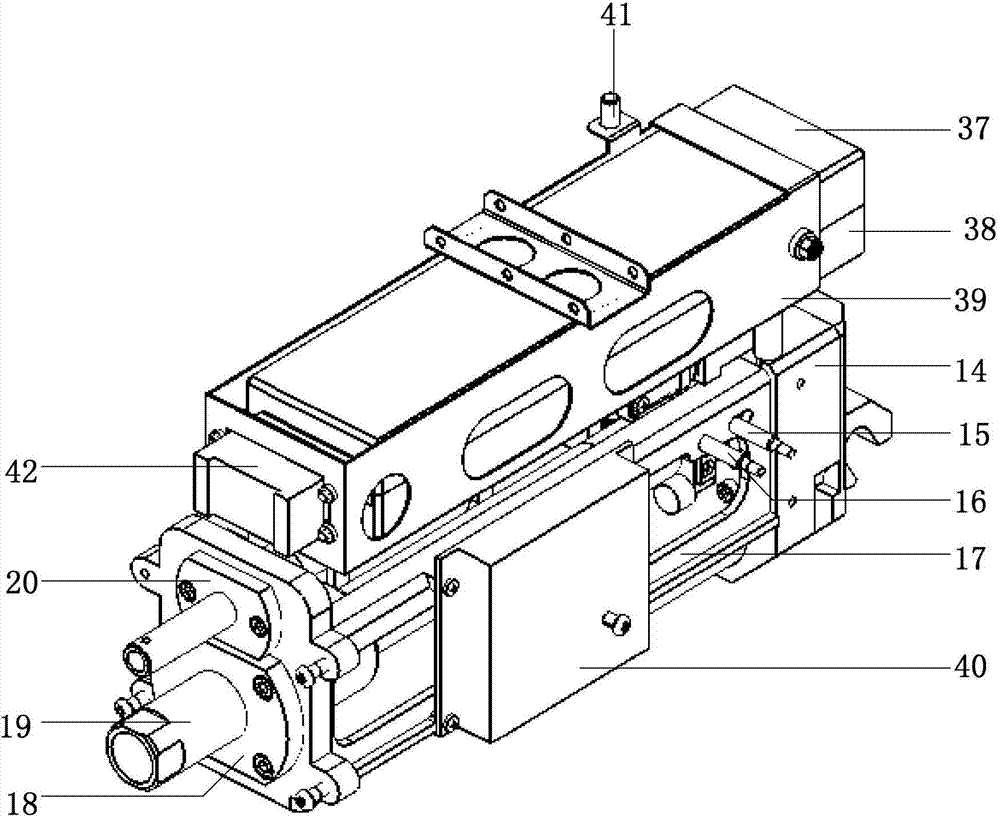

[0020] The pedal force detector of the present invention is used for detecting the force applied to the pedal of the motor vehicle, and the main detection parameters are changes of pedal force and stroke, leakage stroke and time. Such as figure 1 As shown, the overall structure of the present invention includes a casing 4, a transmission device and a detection mechanism 6. The transmission device is arranged in the casing 4, and the detection mechanism 6 is arranged at the front end of the casing 4, and is connected with the sliding main shaft 19 and the sliding shaft 19 of the transmission device in the casing 4. Connected to the secondary shaft 7.

[0021] The shell 4 is constructed with profiles, and the bottom of the shell 4 is provided with two adjustment legs 5, which can be adjusted in height, so as to be suitable for detecting the pedal force of different models. The rear end of the shell 4 is connected with a rear end support 3, and the rear end support 3 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com