Sterile filling device

A technology of aseptic filling and filling valve, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. Filling accuracy and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

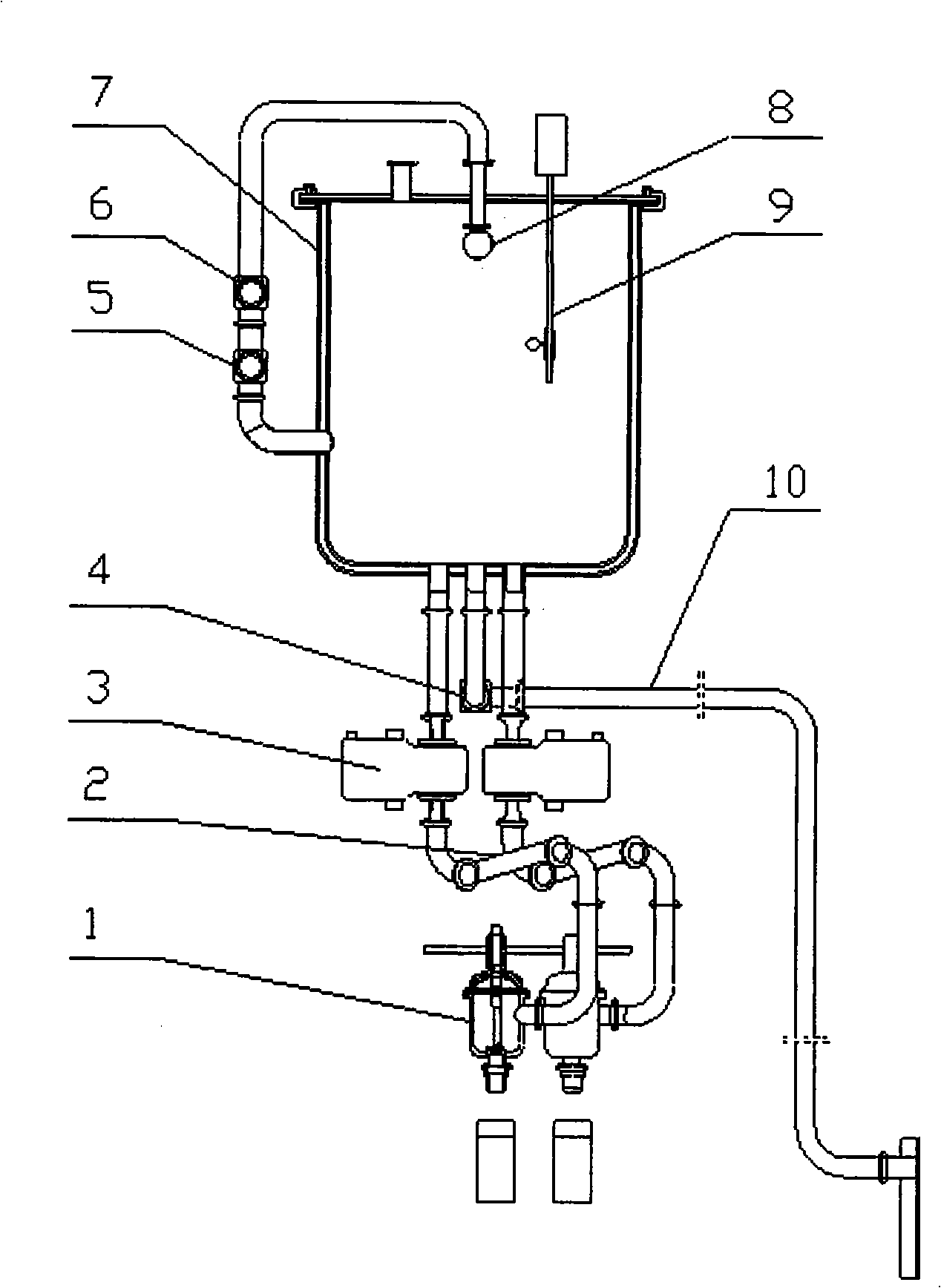

[0021] Such as figure 1 The aseptic filling device shown mainly includes: filling valve 1, silicone hose 2, flow meter 3, discharge valve 4, feed valve 5, stop valve 6, material tank 7, spray ball 8, Liquid level gauge 9 and stainless steel pipeline 10.

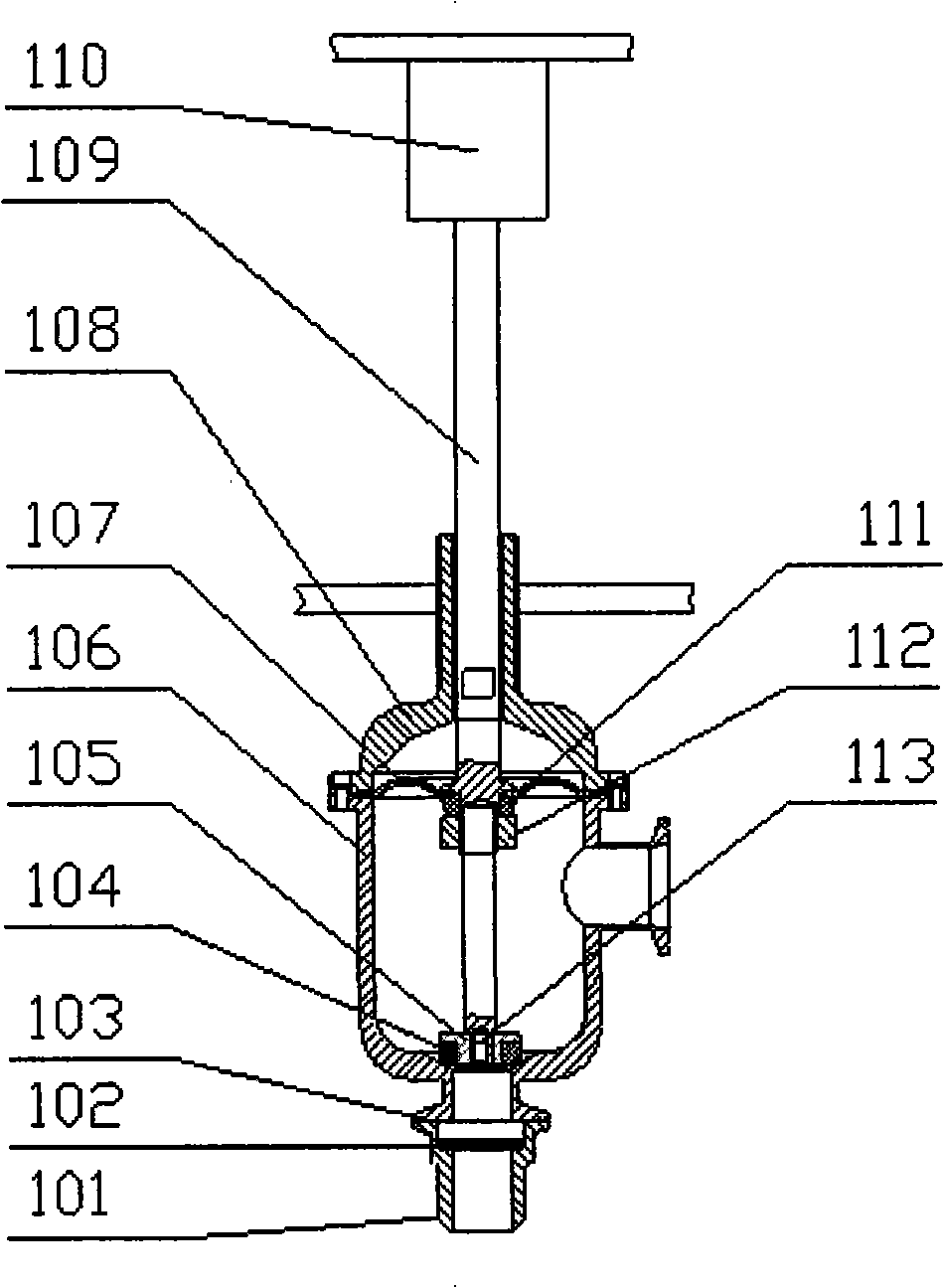

[0022] One of the differences between the present invention and the prior art is that a liquid level gauge 9 is installed on the material tank 7, and the measuring rod of the liquid level gauge 9 is inserted in the material tank 7. The structure includes an exhaust port 91, a screw hole 92, a liquid discharge port 93, a magnetic switch 94, a magnetic ring 95, a nut 96, a cylinder body 97, a slide rod 98, a float 99, a cylinder cover 910, and a signal line 911. Slide bar 98 is housed in the cylinder block 97 and is slidingly matched, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com