Expansive soil cement modifying and filling construction method

A cement modification and construction method technology, applied in construction, soil protection, infrastructure engineering, etc., can solve the doubled construction cost and construction period, the uneven expansion and contraction deformation of modified soil, and the inability to guarantee rolling and filling. The water content of the construction soil and other issues can ensure the effect of the filling quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

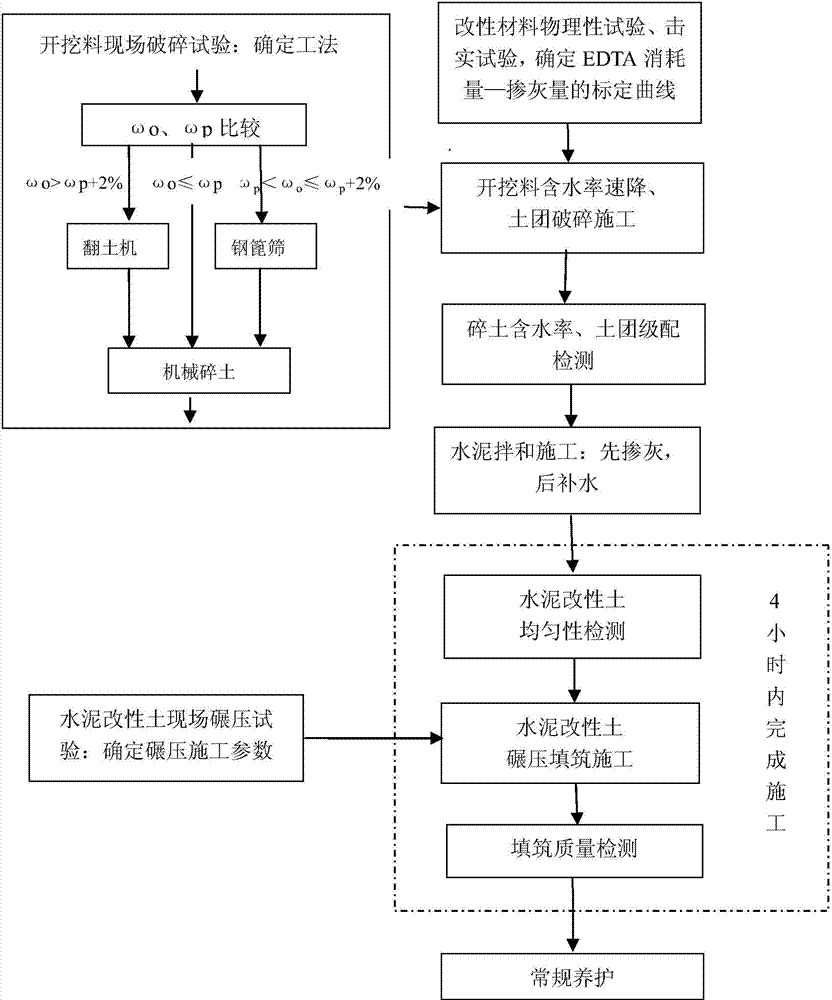

[0043] figure 1 Shown is the schematic flow chart of expansive soil cement modification and filling construction method of the present invention, described expansive soil cement modification and filling construction method comprises the following steps:

[0044] The first step is to conduct the basic property test of the modified material

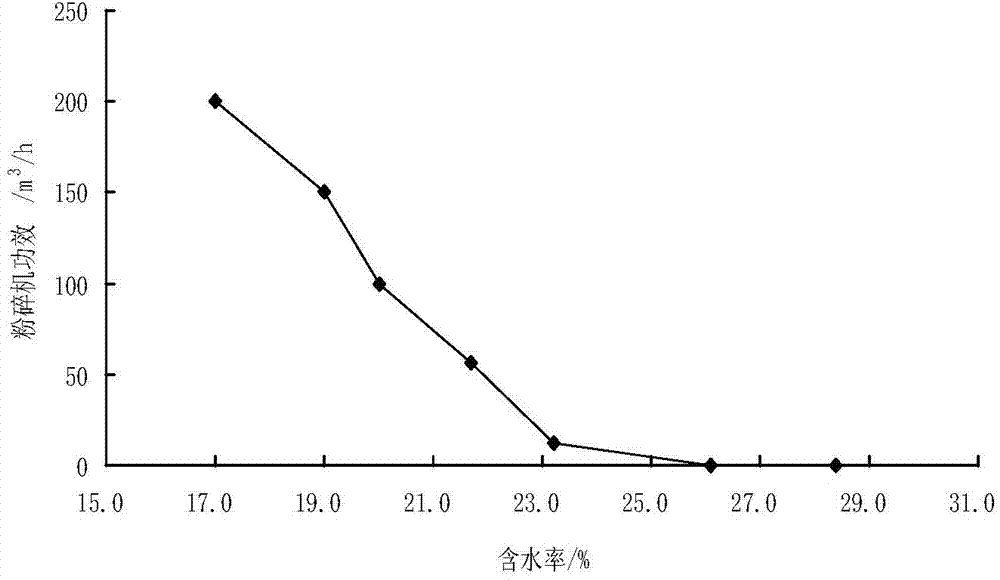

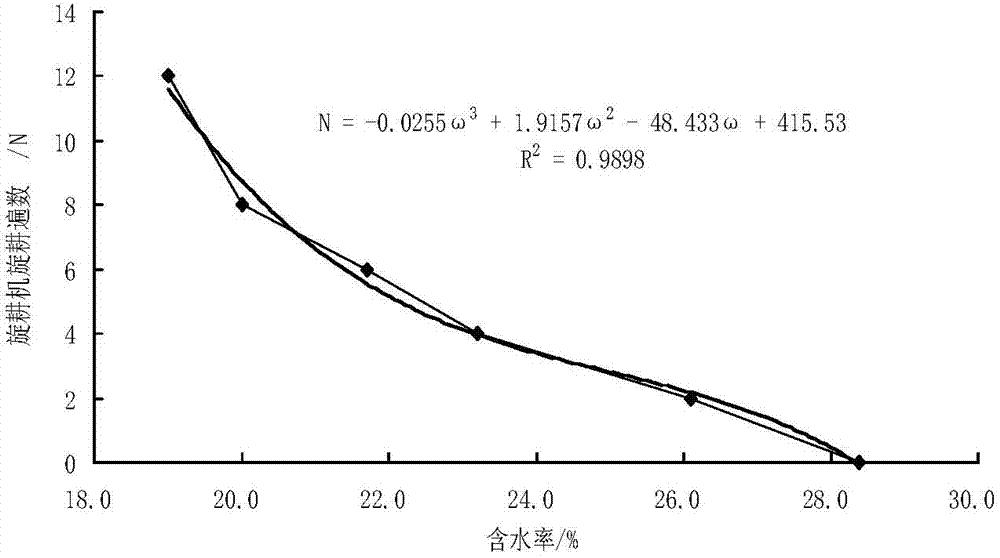

[0045] Test the natural moisture content of excavated expansive soil ω o , plastic limit moisture content ω p , Free expansion rate δ, according to the free expansion rate δ to judge the expansion grade: 65%≤free expansion rate δdmax and optimal water content ω op , as the calculated value of the compaction degree of the cement modified soil material in the on-site rolling test; the indoor EDTA disodium titration test is carried out to determine the calibration curv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com