Method for filling and constructing foam concrete in coal mine soft rock largely-deformed roadway supporter

A technology of foam concrete and roadway support, which is applied in the direction of earthwork drilling, tunnels, mining equipment, etc., can solve the problems of high labor intensity, slow filling speed, poor mechanical properties of filling materials, etc., to ensure construction quality and guarantee filling The effect of uniform quality and force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

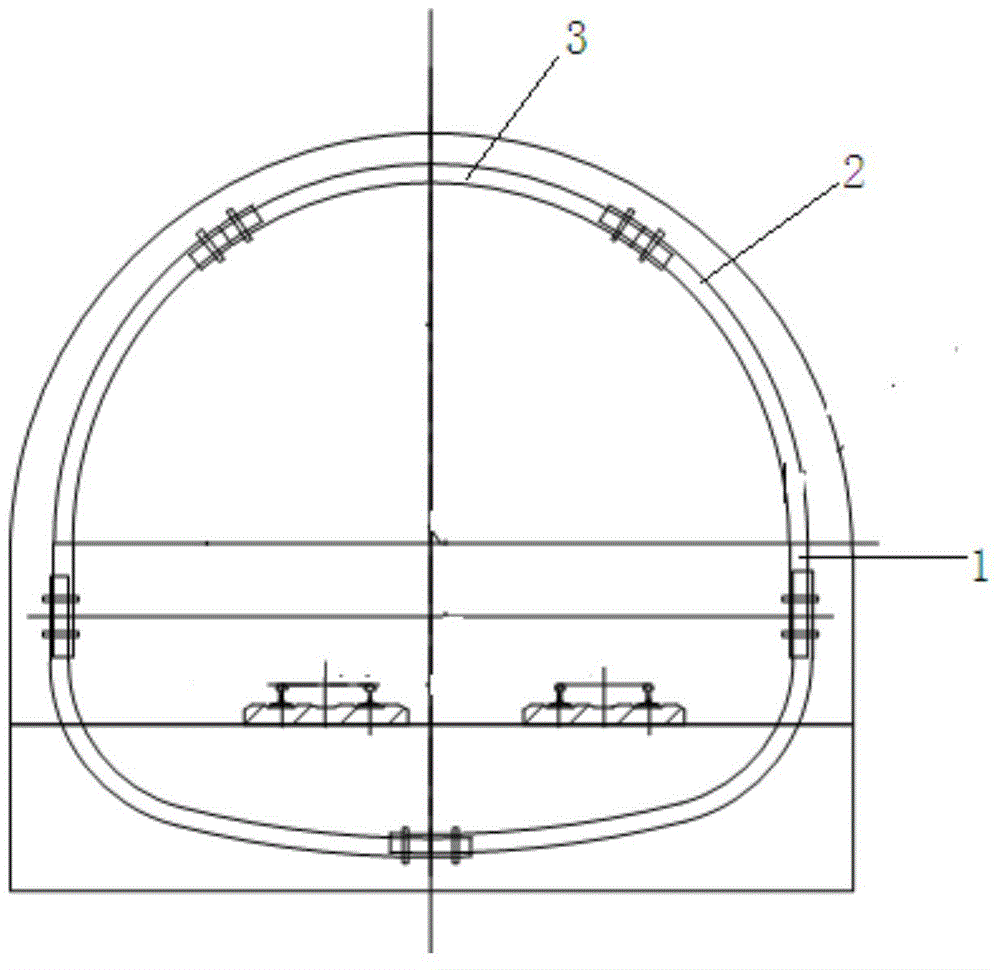

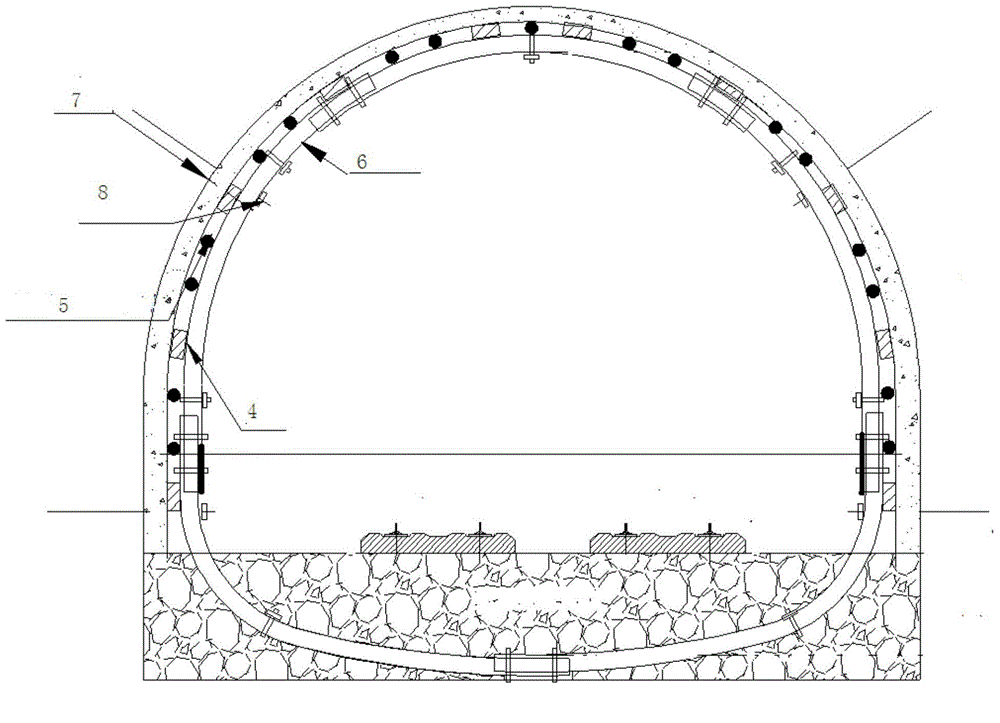

[0025] A filling construction method of foam concrete in the support of large deformation roadway in soft rock of coal mine:

[0026] ① Lay plastic mesh and air duct cloth

[0027] After the shed is erected, lay the filling in units from the outside to the inside along the direction of the roadway. The length of each unit is about 20 sheds. The outer side of the shed is first laid with double-layer plastic nets and air duct cloth (old ones can be used), and each unit is segmented from bottom to top. The lowermost section of the double-layer plastic mesh and air duct cloth is about 500mm deep into the bottom plate, and the adjacent plastic mesh and air duct cloth are overlapped by 100mm.

[0028] When laying the double-layer plastic net and the fan cloth, it can be done together. After the double-layer plastic net is unfolded, it is connected with the fan cloth with 16# iron wire. After the shed, continue to move in series until it is laid in place. Use 12# iron wire to fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com