Steam type antivirus fine-adjustment screening production line

A production line and steam technology, applied in the direction of making medicines into special physical or ingestible devices, types of packaging items, caps, etc., can solve problems such as too many steps, affect the quality of medicine liquid, increase labor costs, etc., and achieve cost Low cost, simple and compact structure, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

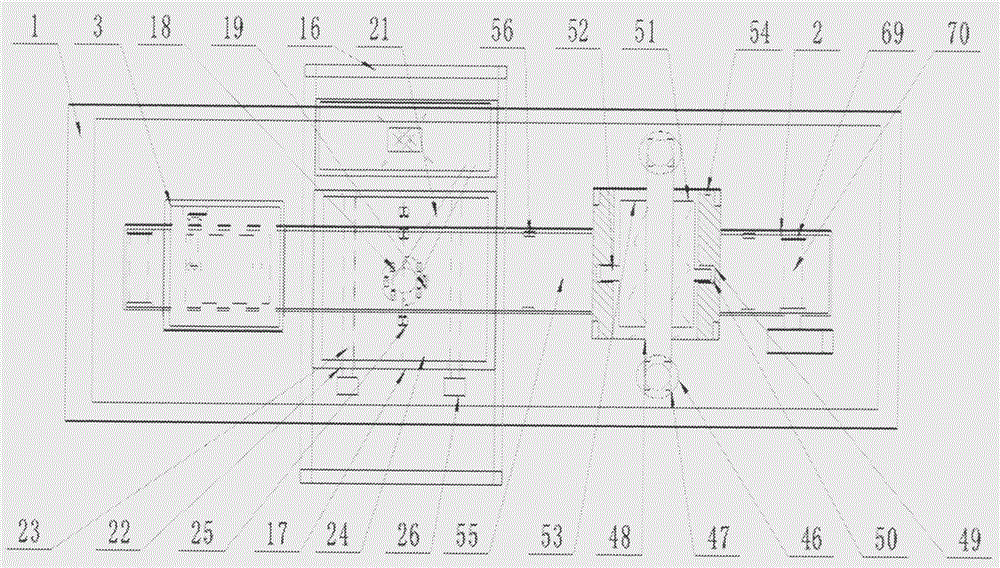

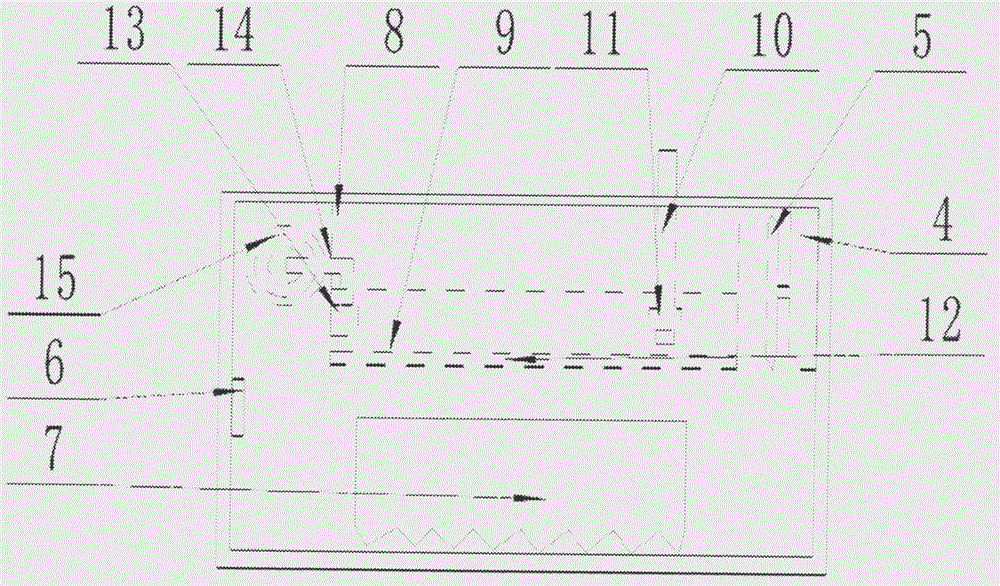

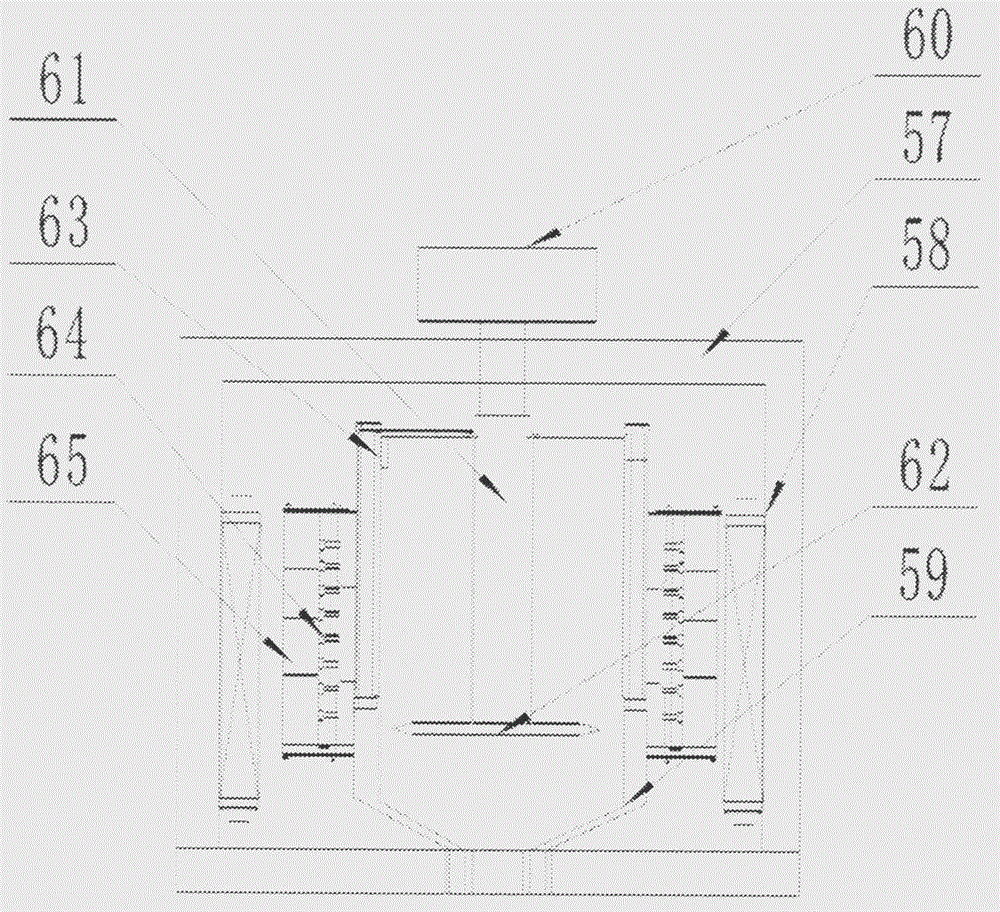

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6As shown, a steam-type antivirus fine-tuning screening production line includes a base (1), the upper surface of the base (1) is provided with a channel (2) along its length, and the channel (2) is provided with There is a transmission mechanism, and the upper surface of the base (1) is sequentially provided with a steam disinfection mechanism, a dripping pill filling mechanism, and a bottle cap hot-press sealing mechanism along its length direction, and the steam disinfection mechanism is fixedly installed on the base (1) ) on the surface of the disinfection box (3) with both sides connected, a steam generating device fixedly installed on the inner upper surface of the disinfection box (3), and a steam generator located on the inner upper surface of the disinfection box (3) and next to the steam generating device The circulation device (4), the six-petal fan (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com