Multi-layered structure and construction method of high embankment near mountains

A construction method and high filling technology, applied in filling, roads, roads, etc., can solve the problems of large cumulative settlement of embankments, difficulties in construction control, and many filling problems, so as to reduce uneven settlement of foundations and realize road construction. Use function, effect of unimpeded drainage of roadbed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

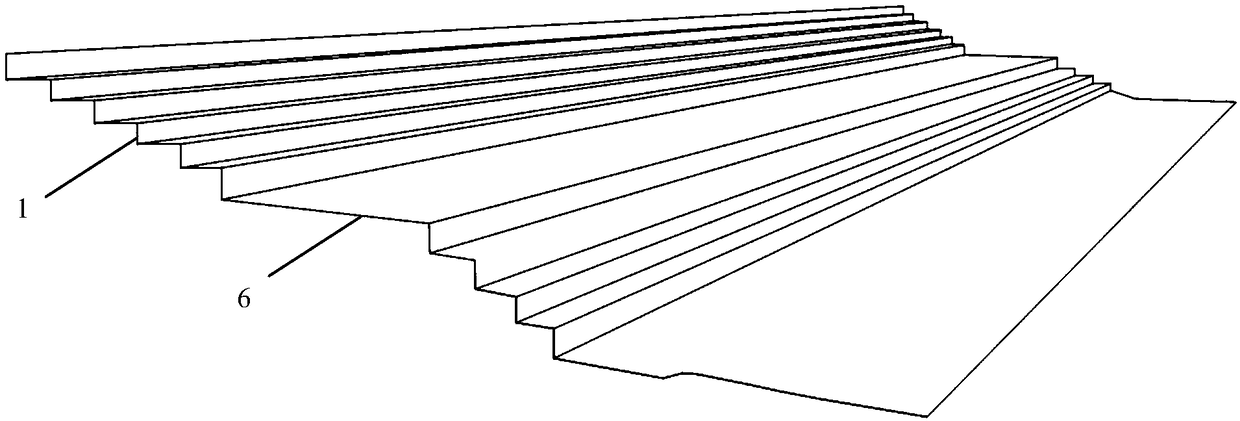

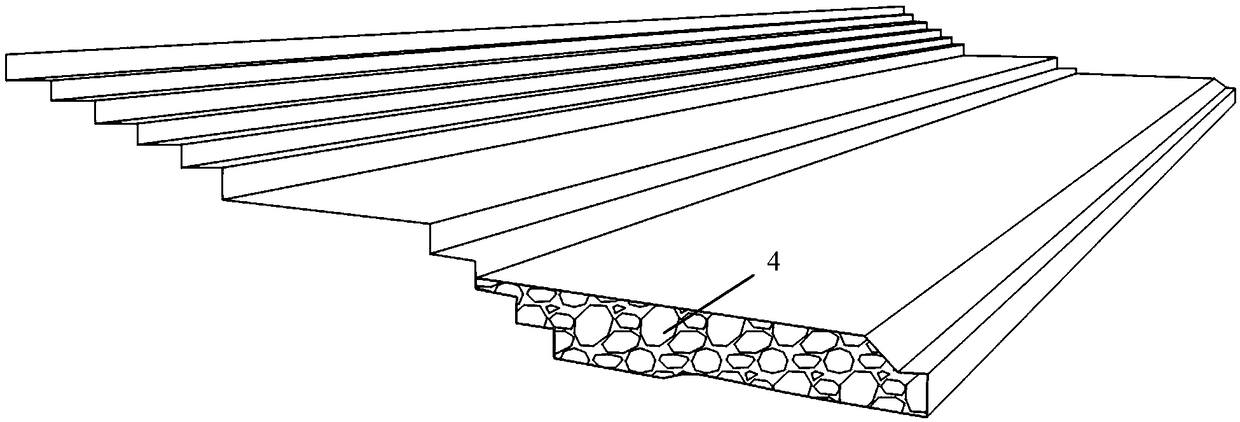

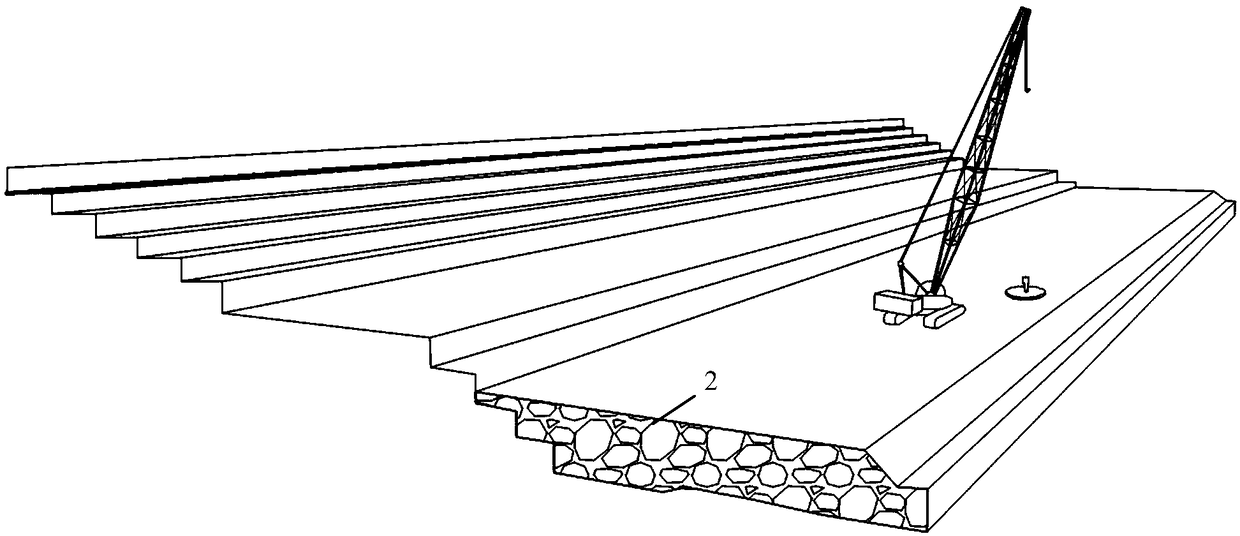

[0034] The multi-level structure of the high fill roadbed next to the mountain of the present invention has the following characteristics:

[0035] 1. Reasonable multi-level structure design and prominent base layer dynamic ramming method to ensure sufficient bottom strength and stability of the rock-filled embankment.

[0036] 2. The high embankment shall be surveyed and designed as an independent work site. On the basis of mastering the hydrogeological conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com