Method of calculating maximum scour depth of rear part of debris flow drainage canal transverse sill and applications

A technology for scour depth and debris flow, applied in the direction of measuring devices, instruments, etc., can solve problems such as damage to the drainage channel project, increased construction costs, and difficulty in accurately determining the design burial depth of the rib sill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

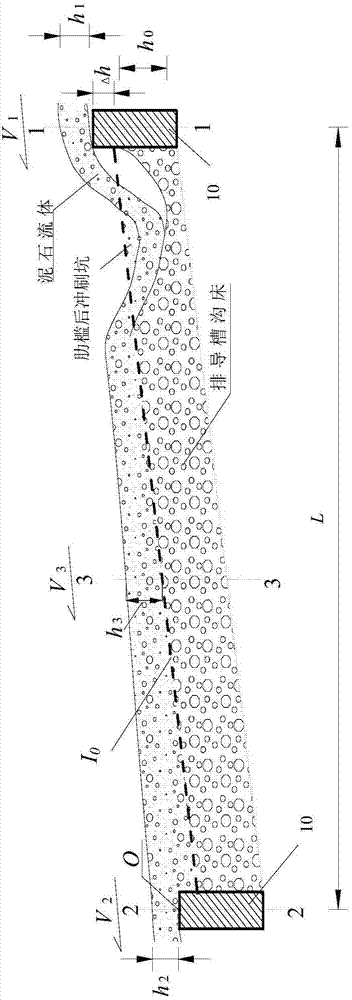

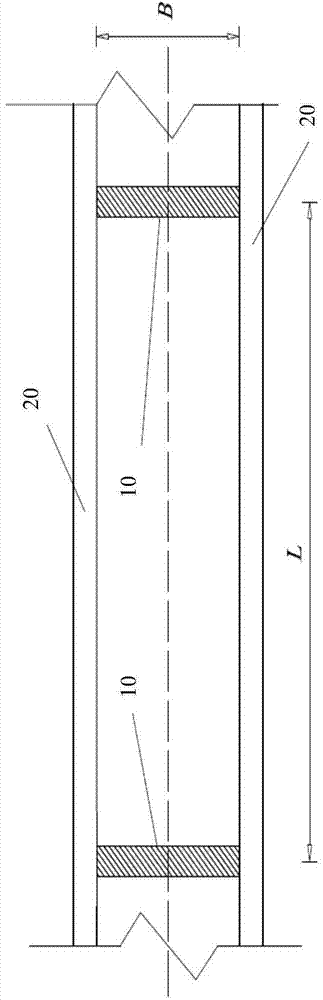

[0073] Such as figure 1 , figure 2 shown. A debris flow ditch is a medium-sized debris flow ditch with an altitude of 1920m to 3500m and a drainage area of 12.2km 2 . There have been many mudslides in the ditch, which seriously threatened the safety of local people's lives and properties. In order to reduce debris flow disasters, it is planned to build a drainage channel project on the debris flow accumulation fan. The debris flow drainage trough includes a number of groove bottom transverse penetrating rib sills 10 arranged at certain intervals and side walls 20 of the drainage trough on both sides. The total length of the drainage trough is 1 km. design, the steps are as follows:

[0074] The first step is to determine the vertical slope I of the design of the row guide groove through the measurement and calculation of the large-scale topographic map 0 It is 0.10; through field investigation and combined with the actual situation of the project, it is determined tha...

Embodiment 2

[0082] Such as figure 1 , figure 2 shown. A debris flow ditch is a very active viscous debris flow ditch. The drainage area of the ditch is 3.7km 2 , the main ditch is 2.5km long, the highest point elevation of the basin is 3061m, and the lowest point elevation is 2400m. Frequent mudslides occurred in the ditch, posing a serious threat to local traffic, industrial and agricultural production, and urban safety. In order to reduce debris flow disasters, it is planned to build a debris flow drainage channel on the accumulation fan of the ditch. The debris flow drainage trough includes a number of horizontally penetrating rib sills 10 arranged at certain intervals and side walls 20 of the drainage trough on both sides. The foundation burial depth of the rib sill 10 is designed below, and the steps are as follows:

[0083] The first step is to determine the design vertical gradient I of the row guide groove through on-site investigation and measurement. 0 It is 0.08; throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com