Device for cutting slot-shaped seats in wells by hydro-sandblasting method

a technology of hydro-sandblasting and slot-shaped seats, which is applied in the field of mining, can solve the problems of inability to control the speed of perforator b>3/b> movement in the cutting process, difficulty in practical cutting slots with desired parameters, and inability to meet the requirements of the desired parameters, etc., to achieve the effect of simplifying the device, reducing the list of shortcomings, and enhancing the convenience, reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

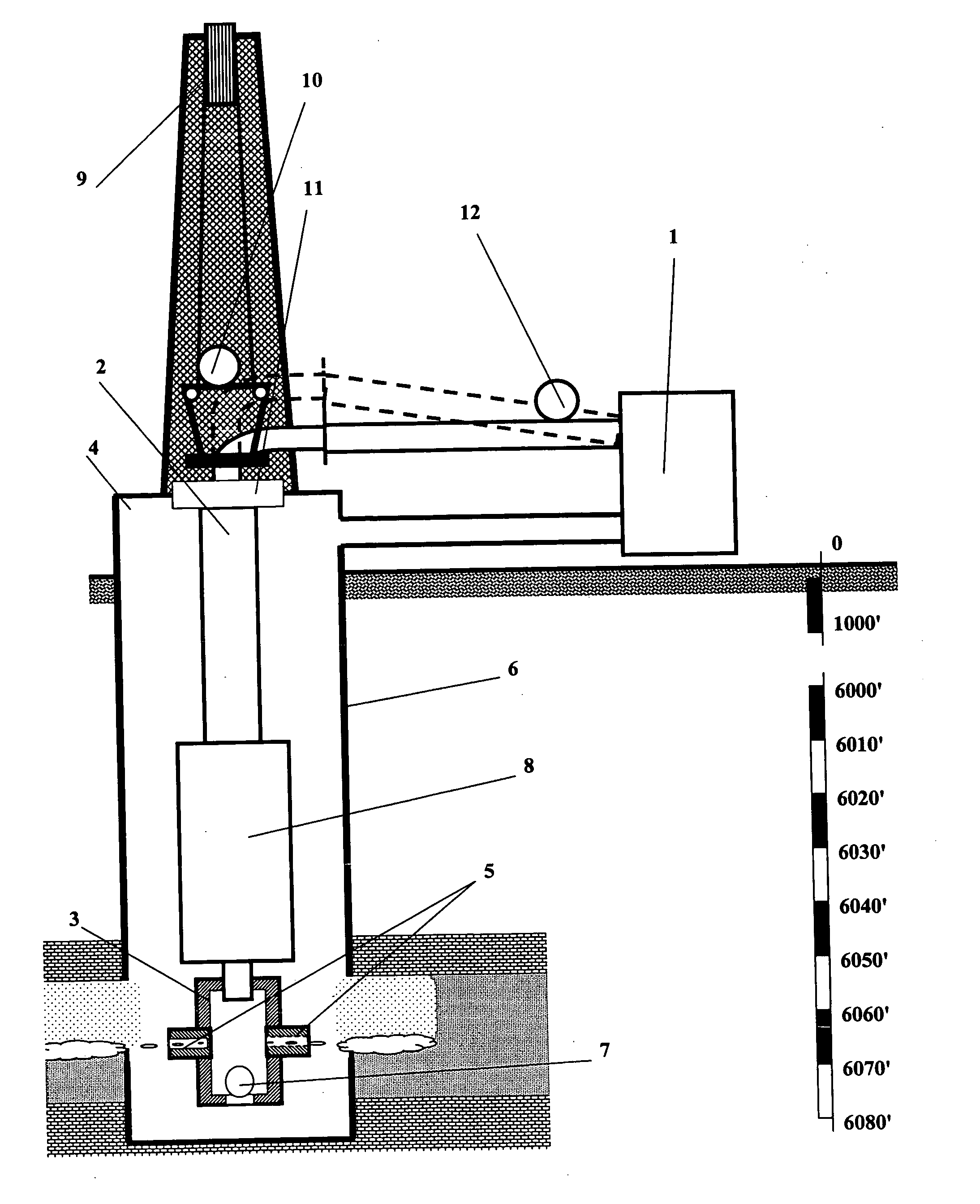

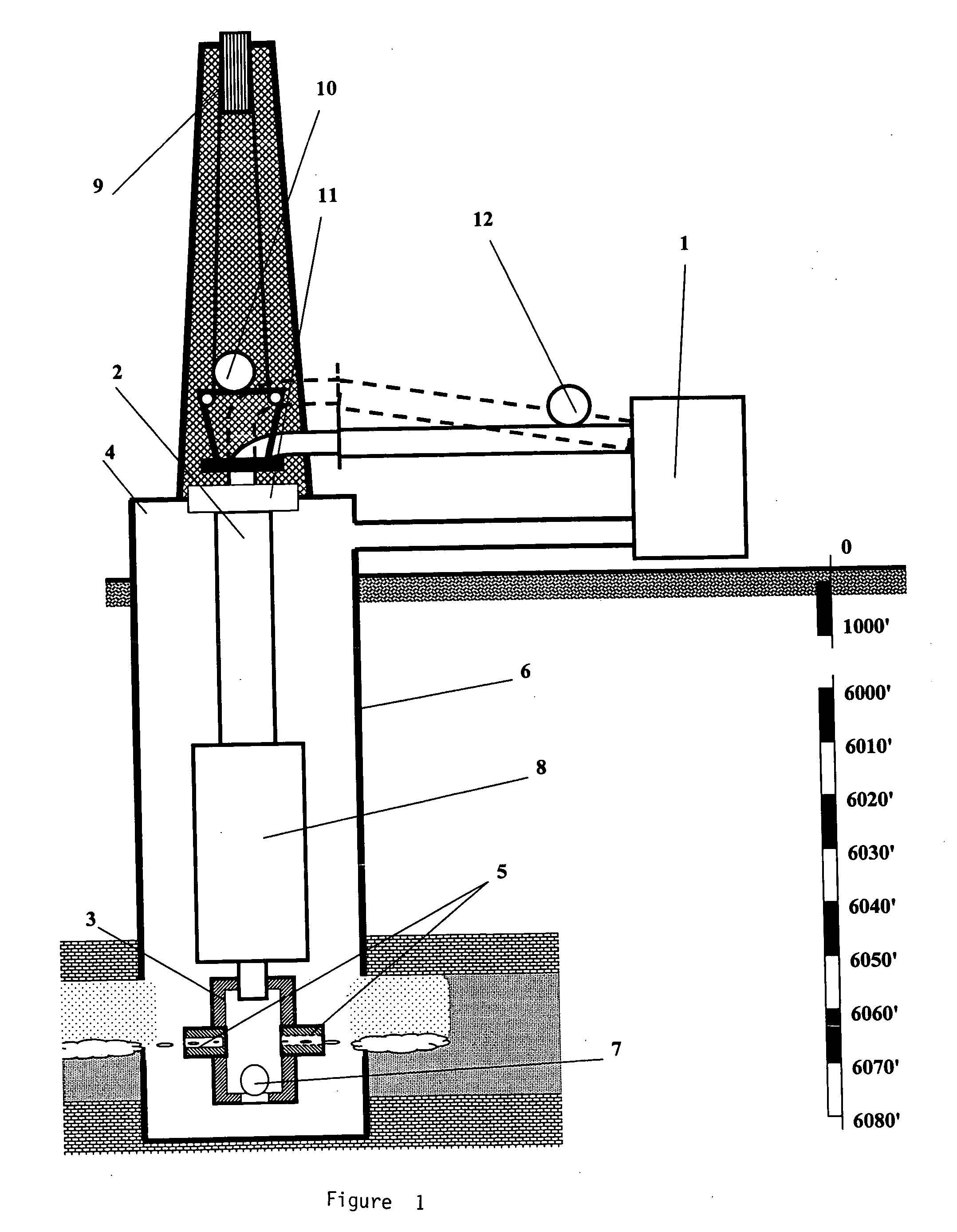

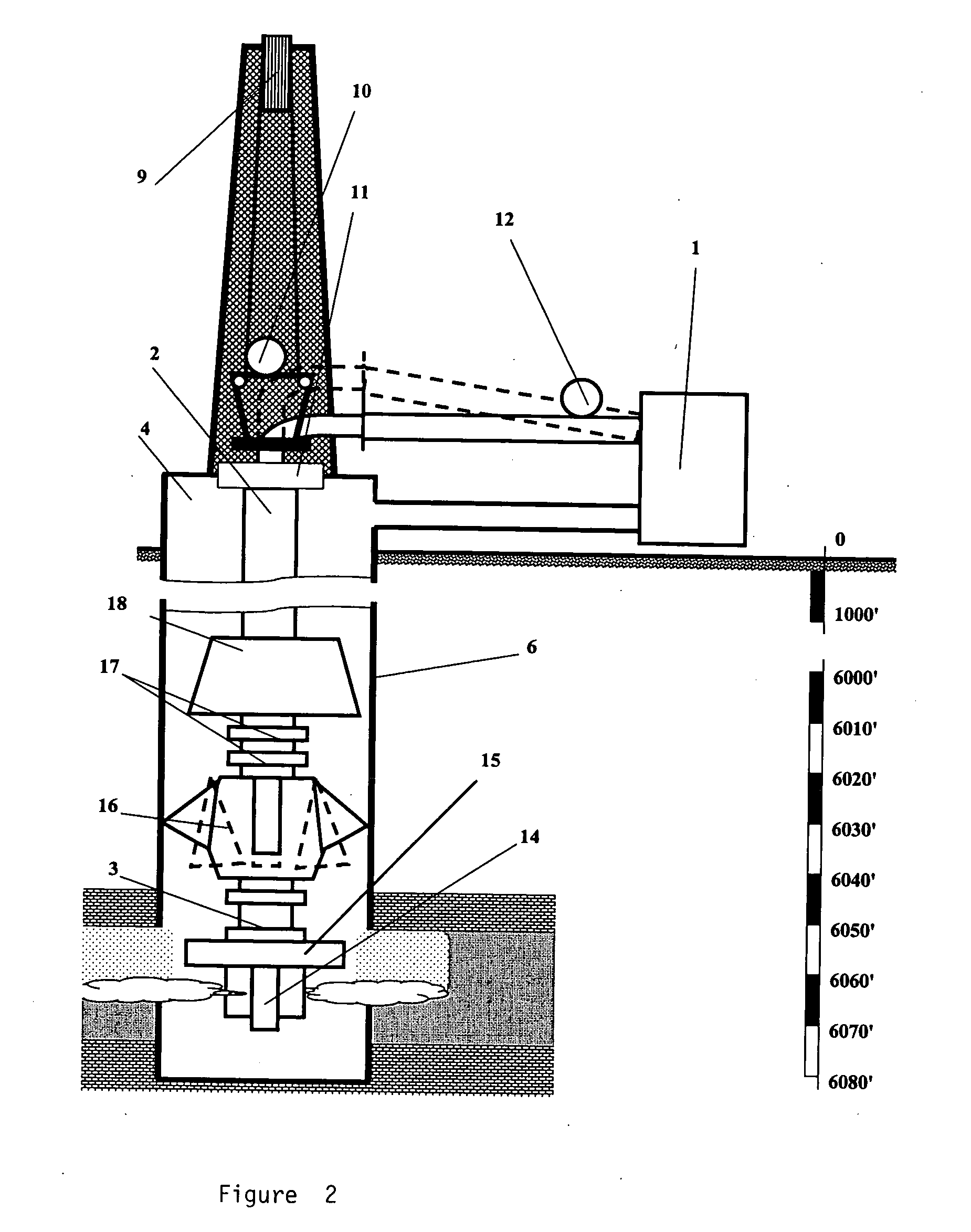

[0019]The determined task is solved by introducing essential changes into the known device for construction of cutting slot-shaped seats from the well wall inside the rock consisting of the hydro-abrasive jet generator connected with the perforator through the tubing string; the perforator is put into the casing pipe and has two diametrical nozzles which are directed at the well wall; there is a ball valve at the perforator end, as well as devices for adjustable partial unloading of PCS, PCS weight measuring device, abrasive jet pressure measuring device and the sealer for sealing of wellhead.

[0020]The changes are as follows:[0021]The perforator is directly connected with PCS;[0022]A pin mounted under the perforator with possible axial movements is introduced;[0023]A cylindrical retainer washer is put on the upper part of the perforator above nozzles; the washer is fixed so as to permit axial movement;[0024]PCS indexing mechanism, step rings and a tripping muff are mounted bottom u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com