Panel construction method of concrete faced rock-fill dam

A technology of concrete slab and construction method, which is applied in the direction of filling, dams, barrages, etc., can solve the problems of shortened pouring time intervals and quality problems, and achieve the effects of reducing uneven settlement, preventing structural cracks, and avoiding voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

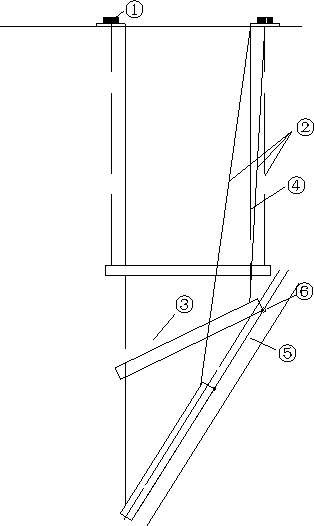

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with the specific construction method of the main dam of the Gongboxia Hydropower Station on the Yellow River as an example.

[0023] The Gongboxia Hydropower Station of the Yellow River is located on the main stream of the Yellow River at the junction of Xunhua County and Hualong County in Qinghai Province. The upstream is 76km away from Lijiaxia Hydropower Station, the downstream is 148km away from Liujiaxia Hydropower Station, and 153km away from Xining City. The traffic conditions are convenient.

[0024] This project is a first-class large (I) project mainly for power generation, and also for irrigation and water supply. The total storage capacity of the reservoir is 620 million m 3 , the adjustment storage capacity is 75 million m 3 , for daily regulation of the reservoir. The installed capacity of the power station is 1500MW (five units with a capacity of 300MW), the guaranteed output is 492MW, and the avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com