Control method of wall cracks based on temperature monitoring

A control method and wall technology, applied in the direction of walls, building materials processing, building components, etc., can solve problems such as concrete surface cracks that cannot be effectively solved, and achieve the effects of preventing structural cracks, efficient control, and avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

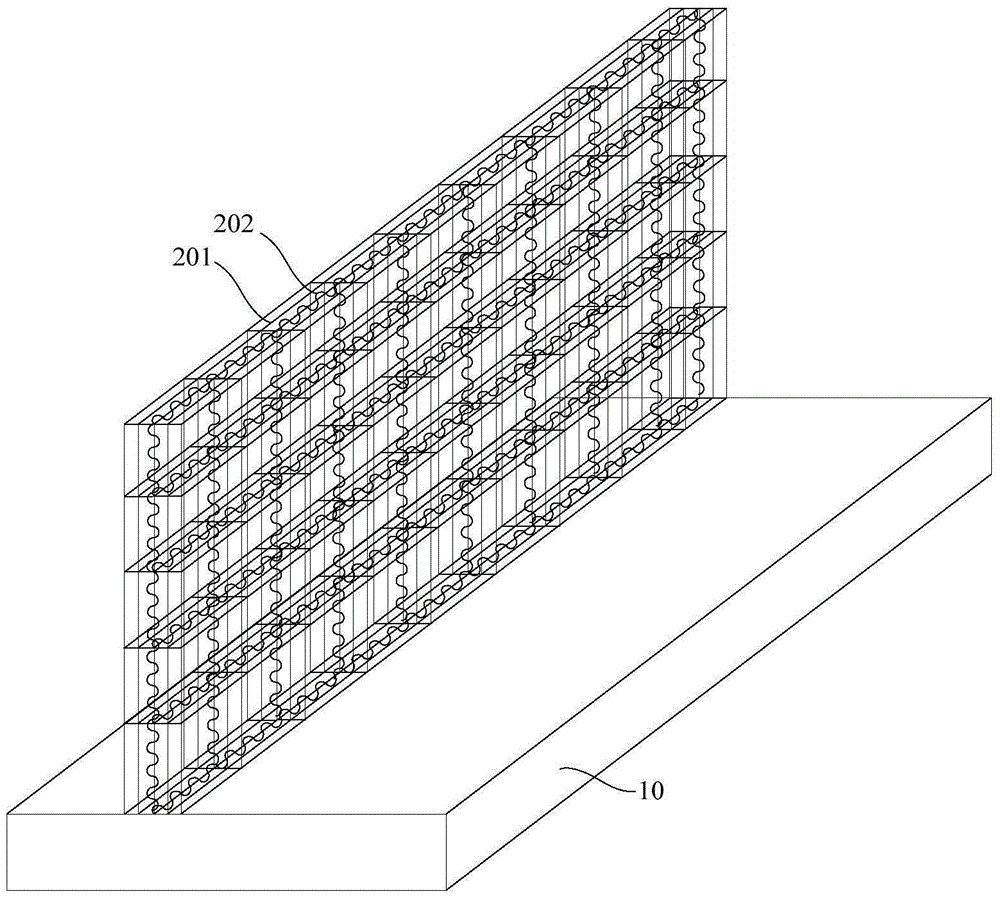

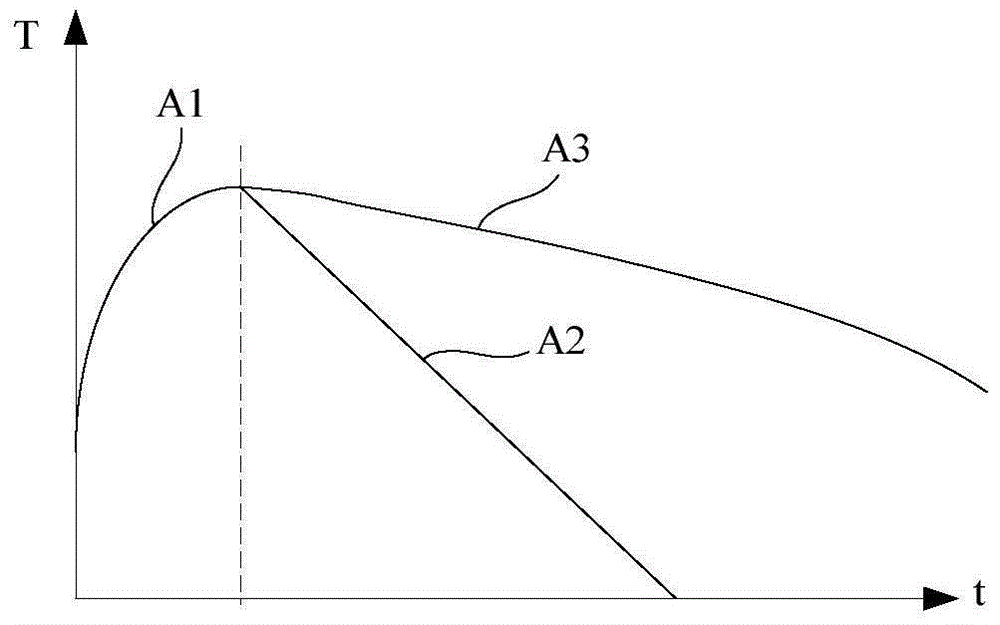

[0024] The invention provides a method for controlling cracks in a wall based on temperature monitoring. An electric heating device is installed on a reinforcement cage in the wall. During the solidification process of the concrete in the wall, the electric heating device is controlled to supply heat to the concrete in the wall, so that The temperature of concrete can drop slowly, avoiding the problem of wall cracks caused by thermal expansion and contraction when the temperature drops rapidly. Compared with the existing method of using the thermal insulation film, the present invention can realize real-time control of the concrete of the wall body, and has high precision of temperature control. In addition, the ideal curve of concrete temperature drop is also preset, that is, the change curve of the preset temperature, and then the real-time t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com