Construction Method of Filling Masonry and Frame Shear Wall to Prevent Interface Cracks

A technology of crack structure and construction method, applied in the direction of walls, building components, building structures, etc., can solve the problems of reducing the wall, forming cracks, poor integrity, etc., to prevent damage, prevent structural cracks, and enhance connection stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In this embodiment, the steel structure welding process, bolt connection construction process, formwork setting process, etc. will not be repeated in this embodiment, and the embodiment of the structure related to the present invention will be focused on.

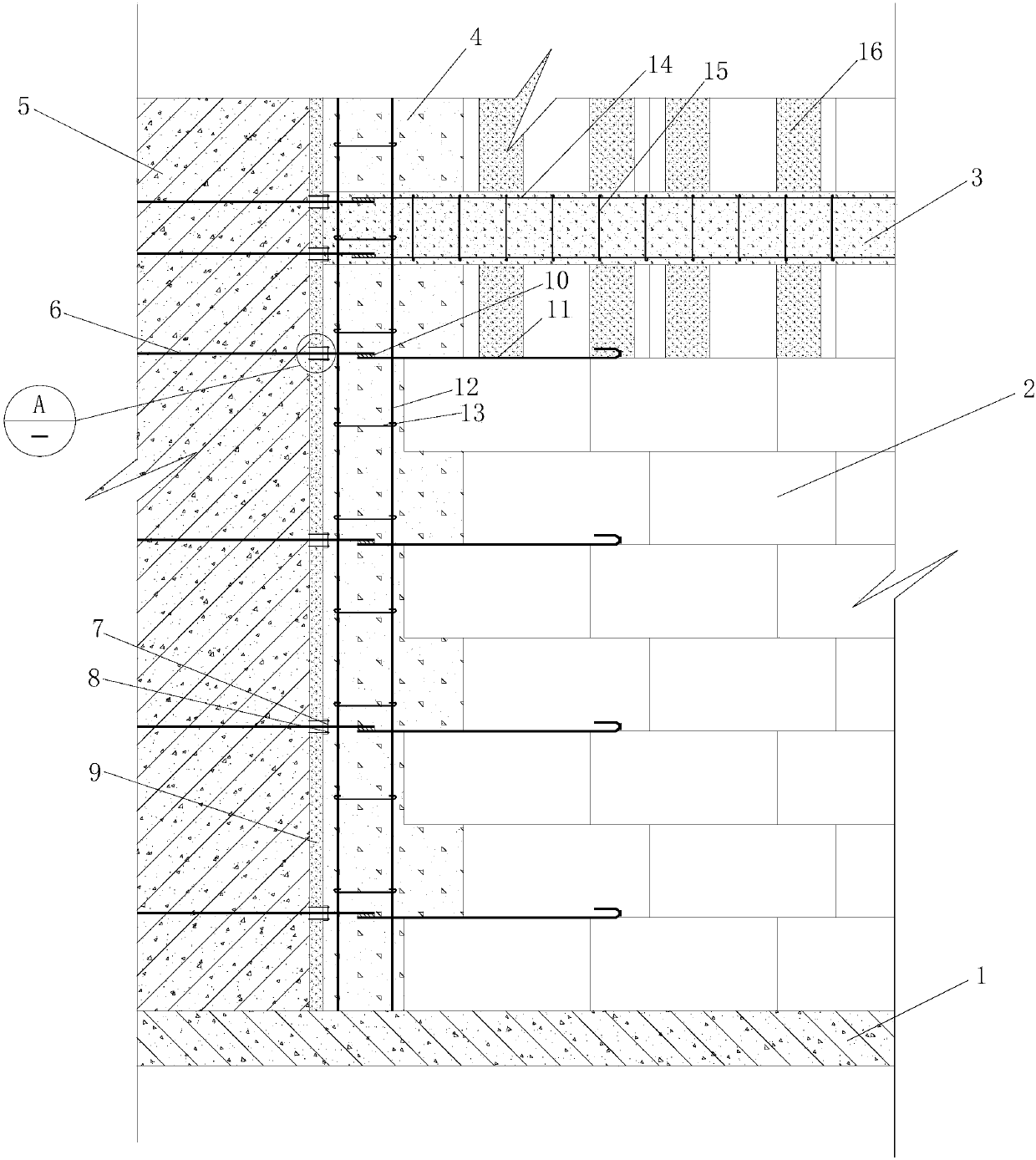

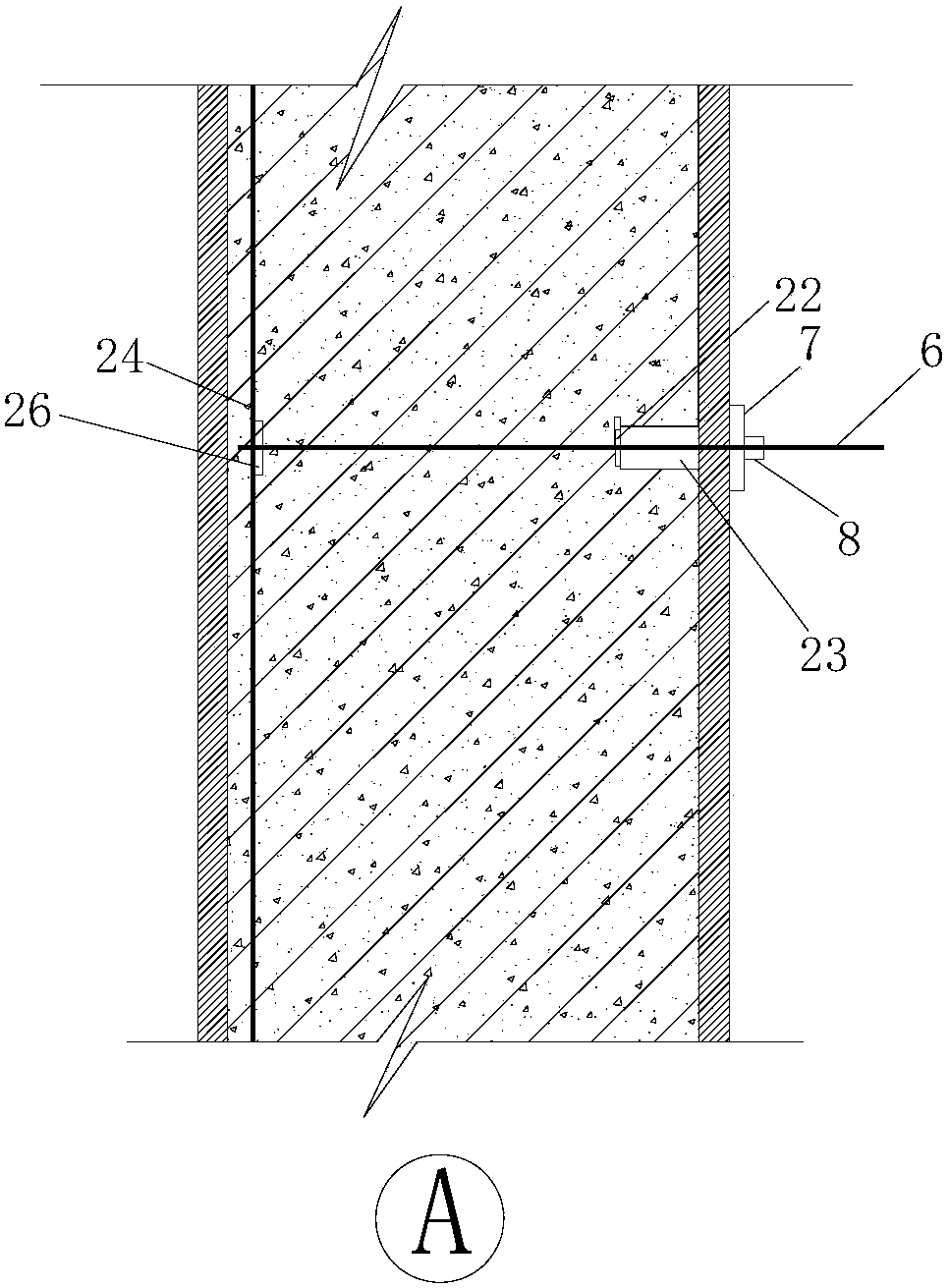

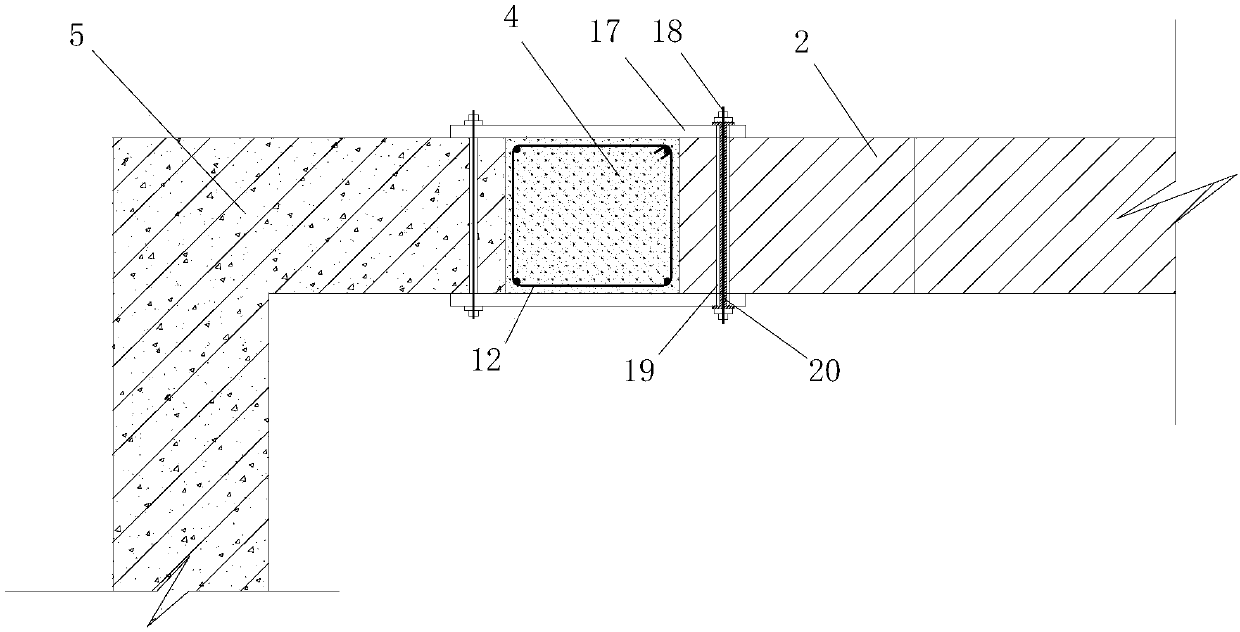

[0026] Filled masonry and frame shear wall structure to prevent interface cracks, including: floor 1, block wall 2, ring beam 3, horse-shaped structural column 4, structural wall column 5, wall column reserved reinforcement 6, steel anchor 7. Fixing bolts 8, concrete rough surface 9, steel bar connecting sleeve 10, wall tension bars 11, structural column longitudinal bars 12, structural column stirrups 13, ring beam longitudinal bars 14, ring beam stirrups 15, concrete pouring body 16. Structural column formwork 17, opposite pull screw 18, PVC sleeve 19, screw steel sleeve 20, steel wire mesh 21, positioning block 22, plastic block 23, wall column main reinforcement 24, hanging net reinforcement 25, pre-embedded reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com