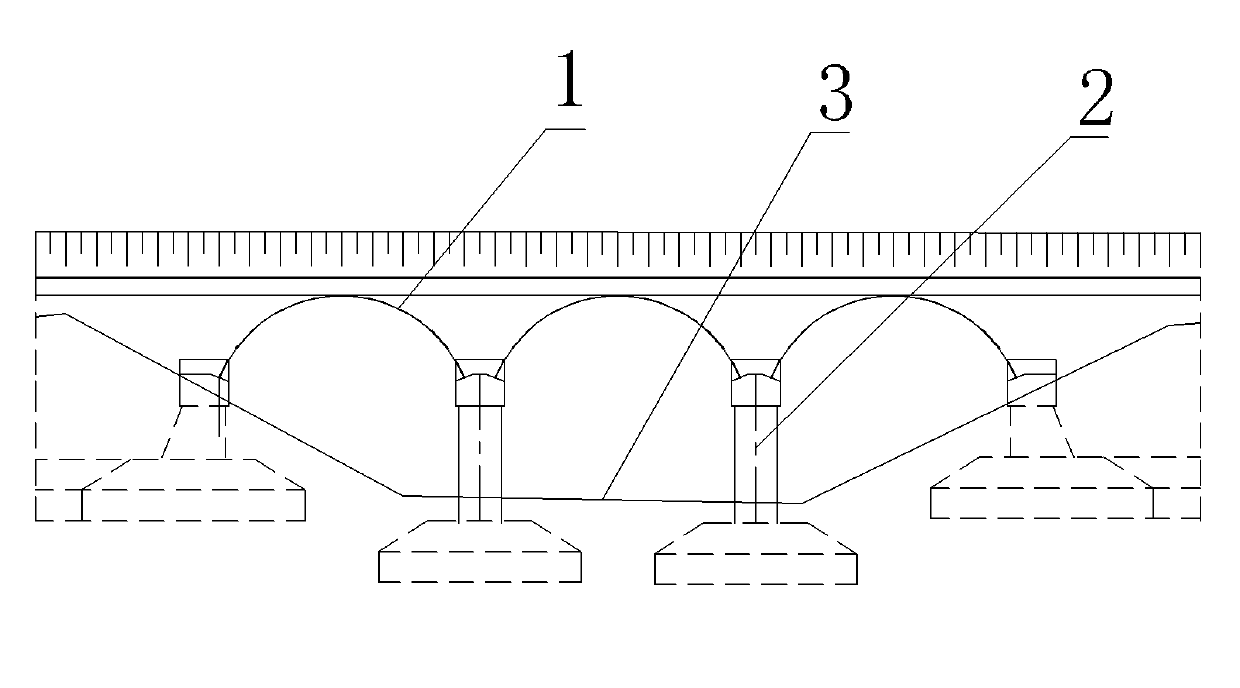

Circular-arched steel-corrugated-plate bridge and culvert structure

A corrugated plate, plate bridge and culvert technology, which is applied in the direction of buildings and road bottoms, can solve the problems of not being able to adapt well to foundation deformation and uneven settlement, affecting the applicable function and life of structures, and being unable to effectively buffer earthquake damage. Achieve the effects of environmental protection, convenient quality control, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

[0022] The arc-arch steel corrugated plate bridge and culvert structure according to the present invention has a foundation 2 at the lower part, and adopts C30 reinforced cement concrete. The upper part of the foundation 2 is provided with a single-span or multi-span bridge arch, and the bridge arch is a steel corrugated plate arc arch 1, which is composed of steel corrugated plates assembled and fixed by bolts. Such as figure 1 For the three-span steel corrugated arch bridge culvert shown, the steel corrugated arch 1 has a radius of 2.1648m, a central angle of 135°, a radius of curvature of 4.33m, a single span of 4m, and a height of 1.3365m . The corrugation of the corrugated steel plate is axial corrugation, the wave shape is 150mm×50mm×28mm, and the thickness of the covering soil on the top of the plate is 1.08m. The arch spacing of the steel corrugated plate arc a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com