Mudstone filled roadbed structure and construction method thereof

A construction method and pavement structure technology, which is applied in infrastructure engineering, roads, excavation, etc., can solve the problems affecting the construction progress of the project, the large proportion of super-sized particles, and the instability of the base, so as to improve the single-layer and overall Strength and compaction, improved overall stability and strength, reduced uneven settlement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Below take the implementation of the North Yanjiang Expressway in Anhui Province as an example to specifically illustrate the present invention.

[0055] The North Yanjiang Expressway is located in the Jianghuai hilly terrain area on the north bank of the Yangtze River. Geological surveys show that the soft rock distributed along the highway is mainly mudstone. Mudstone, sandstone, conglomerate and other rock formations are developed alternately in the K12-K17 section, and mudstone is generally developed in the K24-K31 section. The average annual precipitation in the highway area is 1000-1200mm.

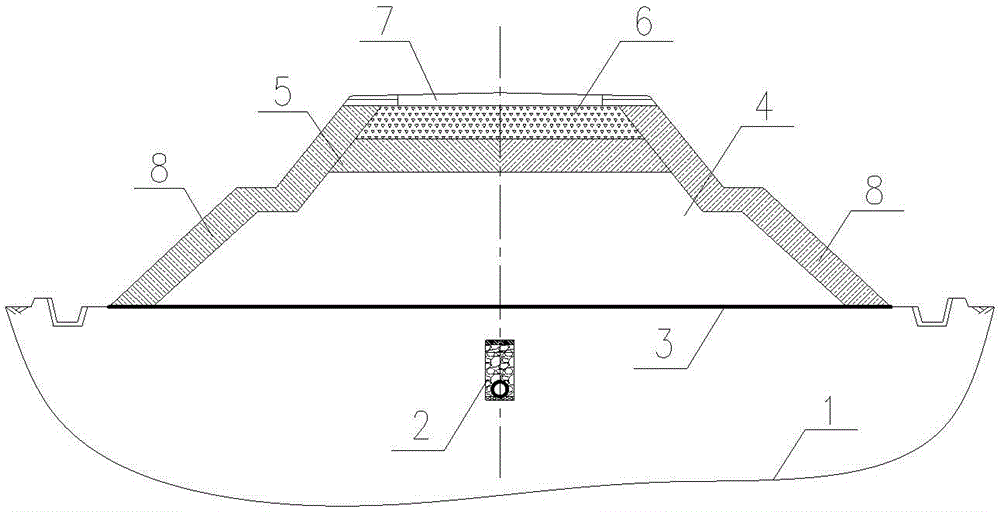

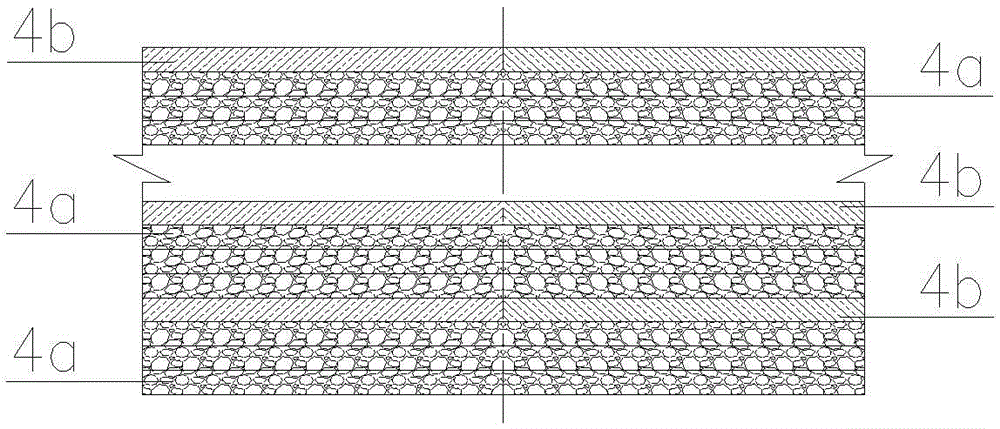

[0056] see figure 1 , the designed mudstone fill embankment structure includes constructing the catchment tank 2 in the soil foundation 1, laying an impermeable layer 3 on the surface of the soil foundation 1, and constructing the lower embankment 4, the upper embankment 5, and the road bed on the impermeable layer 3 in sequence 6 and the pavement structure layer 7; build cla...

Embodiment 2

[0078] The impermeable layer 3 in this embodiment is a waterproof board with a thickness of not less than 0.8mm, the waterproof board is an HDPE waterproof board, the tensile strength is not less than 17MPa, and the right-angle tear strength is not less than 110N / mm.

[0079] Other structures are with embodiment 1.

[0080] Construction operation method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com