Construction method and structure of water seepage roadbed slope drainage system

A technology of drainage system and construction method, which is applied in the direction of infrastructure engineering, excavation, construction, etc., and can solve problems such as unfavorable stability of slopes and reduction of geological parameters of slopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

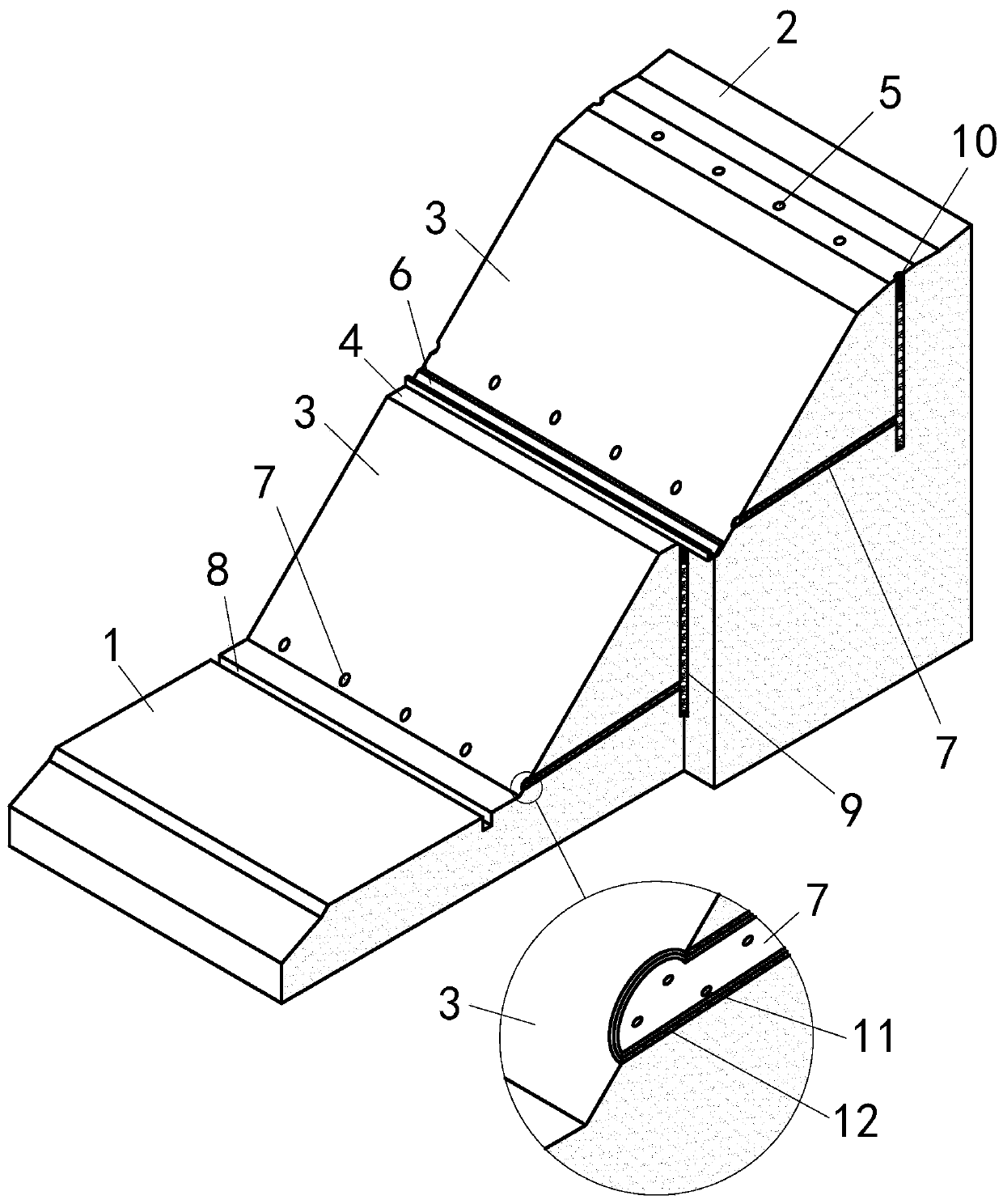

[0020] This example figure 1 As shown, it includes a dewatering well 5, a drainage pipe 7, an intercepting ditch 6, a side ditch 8, and the like. Outside the slope top 2~3 meters position, get the dewatering well 5, the depth of the dewatering well 5 is from the slope top to the bottom height of each level of step plane 4. Fill the water-permeable material 9 in the dewatering well 5, and the water-permeable material 9 is gravel or coarse sand. The groundwater level of the seepage subgrade 1 is lowered through the dewatering well 5, and the top of the dewatering well 5 is sealed with plain concrete or clay 10 at the top of the dewatering well 5. The bottom of each dewatering well 5 is connected with a drainage pipe 7, and the water in the dewatering well 5 is discharged outside the side slope through the intercepting ditch 6 arranged on the step plane 4 or the side ditch 8 on the side of the side slope of the seepage subgrade 1. During slope construction and operation, loweri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com