Cement-based material functionally gradient brick and preparation method thereof

A cement-based material and functional gradient technology, which is applied in the pavement paved with prefabricated blocks, sustainable waste treatment, solid waste management, etc. Even problems such as large settlement can be achieved to reduce water infiltration into the roadbed, avoid road surface diseases, and reduce uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

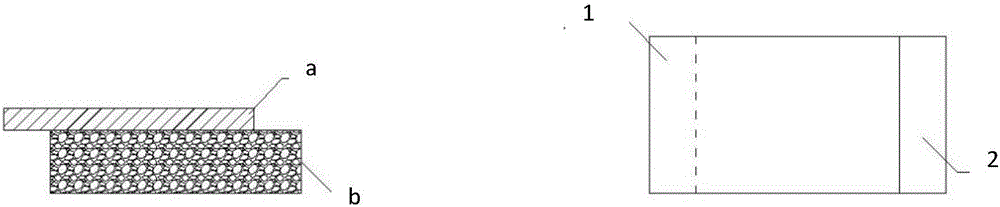

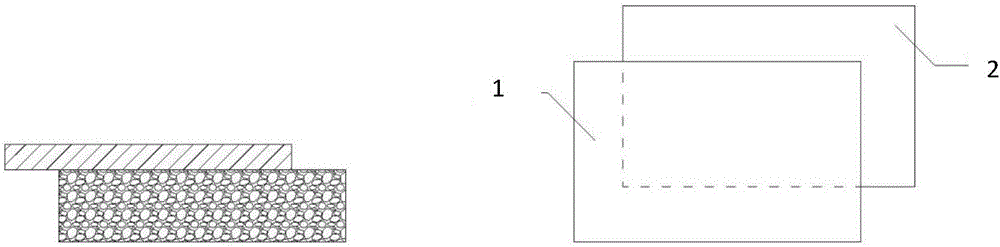

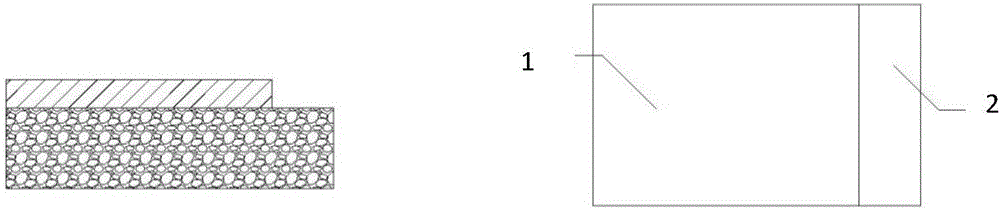

[0042] A preparation method of a cement-based material functionally graded brick, the steps of which are:

[0043] 1) Select the decorative pattern of the surface layer template of the functional gradient brick, prepare the special-shaped mold, and apply the release agent;

[0044] 2) The fiber mortar is pressed into the lower layer of the mold, vibrated and formed, and the cementitious material, fine aggregate, water, water reducing agent and fiber of the formed fiber mortar layer, among which the cementitious material, fine aggregate, water and water reducing agent By weight: 100 parts of cementitious material, 10 to 65 parts of fine aggregate, 20 to 50 parts of water, 0.8 to 1.5 parts of water reducer, and the amount of fiber is 1% of the total volume of the prepared cement-based material toughening layer ~2.5%, the cementitious material includes 15~50 parts of cement, 40~85 parts of fly ash, 0~5 parts of silica fume, 0~10 parts of granulated blast furnace slag powder, and ...

Embodiment 1

[0048] In this embodiment, the fiber mortar layer (fiber cement-based material toughening layer) includes cementitious material, fine aggregate, water, water reducing agent and fiber, wherein cementitious material, fine aggregate, water and water reducing agent are by weight Calculated as: cementitious material, the dosage is 100 parts, the fine aggregate is artificial sand, the dosage is 10 parts, the maximum particle size is 0.5mm, the water dosage is 20 parts, and the dosage of polycarboxylate superplasticizer is gelling 1.2% of the weight of the material, the fiber adopts polyvinyl alcohol fiber, and the dosage is 1% of the total volume of the toughened layer of the prepared cement-based material; the cementitious material is selected from P.O 425 ordinary Portland cement and fly ash, wherein, 15 parts of cement, 85 parts of fly ash;

[0049] The polyvinyl alcohol fiber used has a length of 12 mm, a diameter of 0.039 mm, a tensile strength of 1620 MPa, an elastic modulus o...

Embodiment 2

[0053] In this embodiment, the fiber mortar layer (fiber cement-based material toughening layer) includes cementitious material, fine aggregate, water, water reducing agent and fiber, wherein cementitious material, fine aggregate, water and water reducing agent are by weight Calculated as: cementitious material, the dosage is 100 parts, the fine aggregate is artificial sand, the dosage is 30 parts, the maximum particle size is 0.5mm, the water dosage is 40 parts, and the dosage of polycarboxylate superplasticizer is gelling 1.5 parts by weight of the material, the fiber adopts polyvinyl alcohol fiber, and the dosage is 1% of the total volume of the toughening layer of the prepared cement-based material; the cementitious material is selected from P.O 425 ordinary Portland cement and fly ash, wherein, 40 parts of cement, 50 parts of fly ash, 3 parts of silica fume, 7 parts of granulated blast furnace slag powder;

[0054] The polyvinyl alcohol fiber used has a length of 12 mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com