Flexible pile cap for composite foundation

A composite foundation and flexible pile technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as deformation inconsistency, achieve the effects of increasing bearing capacity, solving deformation inconsistency, and improving deformation inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

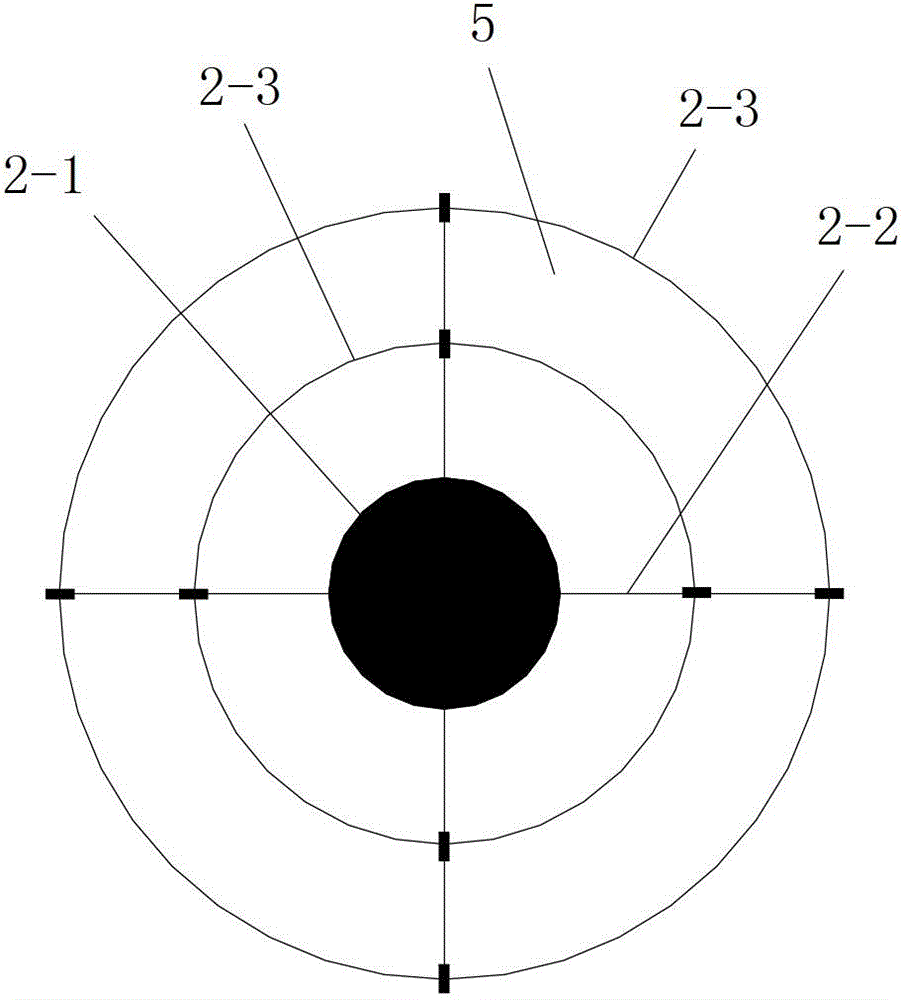

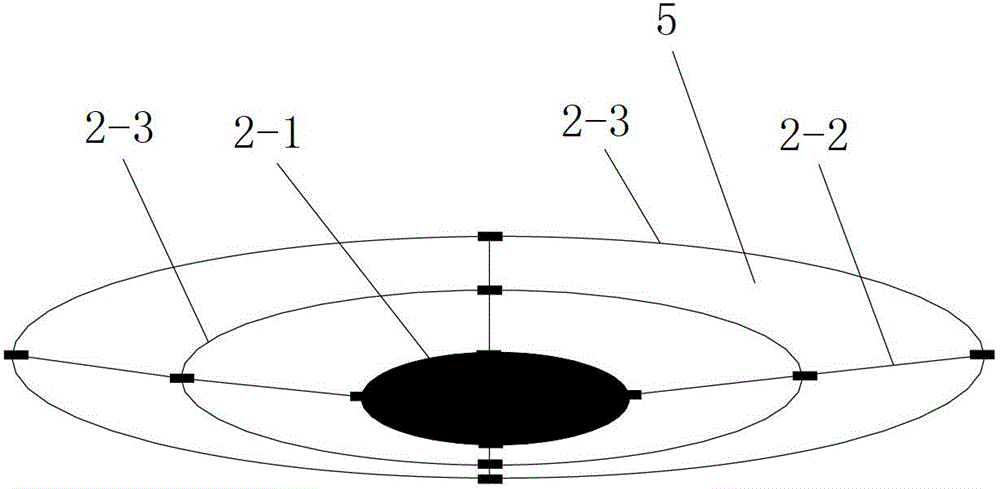

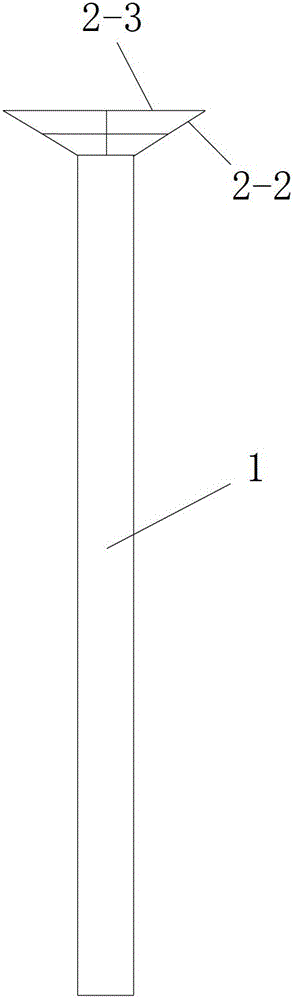

[0048] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a horizontal base 2-1 arranged on the pile top of the reinforcement pile 1, a plurality of oblique stress rods 2-2 arranged above the horizontal base 2-1 along the circumferential direction and arranged on a plurality of said The circular ferrule 2-3 on the oblique force rod 2-2, the plurality of oblique force rods 2-2 are tightly connected as a whole through the circular ferrule 2-3, and the multiple The bottoms of the oblique stress rods 2-2 are all fixed on the horizontal base 2-1, and the plurality of oblique stress rods 2-2 are gradually inclined outward from bottom to top. The number of the plurality of oblique stress rods 2-2 is not less than three. The structures and sizes of the plurality of oblique stress rods 2-2 are the same, and the bottom ends of the plurality of oblique stress rods 2-2 are arranged on the same circle with a diameter of d, and the horizontal base 2-1 is ...

Embodiment 2

[0075] In this embodiment, the difference from Embodiment 1 is: D3=3d, and the included angle α is 35°.

[0076] In this embodiment, the structure, connection relationship and construction process of the remaining parts are the same as those in Embodiment 1.

[0077] After the actual construction is completed, the combined pile cap made in embodiment 1 and the combined pile cap made in embodiment 2 are respectively used on the same treated soft soil; Under the three conditions of the combined pile cap made in Example 1 and the combined pile cap made in Example 2, the force and settlement displacement in the vertical direction at the same position in the mattress layer 4 are monitored respectively , the monitoring results are shown in Table 1:

[0078] Table 1 Statistical table of force and settlement displacement monitoring results in the vertical direction

[0079]

[0080] It can be seen from Table 1 that when the combined pile cap is not laid, the force on the monitori...

Embodiment 3

[0082]Such as Figure 5 and Figure 6 As shown, in this embodiment, the difference from Embodiment 1 is that the horizontal base 2-1 is a circular base, and the circular base includes a circular steel ring composed of steel bars and welded and fixed on the The cross-shaped support frame inside the circular steel pipe, the cross-shaped support frame is composed of steel bar one and steel bar two welded, and the circular steel ring and the cross-shaped support frame are arranged on the same plane; The oblique stress rod 2-2 includes two oblique stress rods 1 whose bottoms are respectively fixed at both ends of the steel bar 1 and two oblique stress rods 2 whose bottoms are respectively fixed at both ends of the steel bar 2. At the same time, the outside of the combined pile cap is not covered with geotextile 5 .

[0083] In this embodiment, the steel bar 1 is integrally processed with the two oblique force-bearing rods 1, and the steel bar 2 is processed and manufactured integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com