Tunnel waterproof and drainage structure and method

A technology for drainage structures and tunnels, applied in tunnels, drainage, and tunnel linings, etc., can solve the problems of increased water pressure on the back of the tunnel lining structure, damage to the tunnel lining structure, and blockage of the drainage holes of the tunnel. The effect of reducing maintenance costs and preventing excessive water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

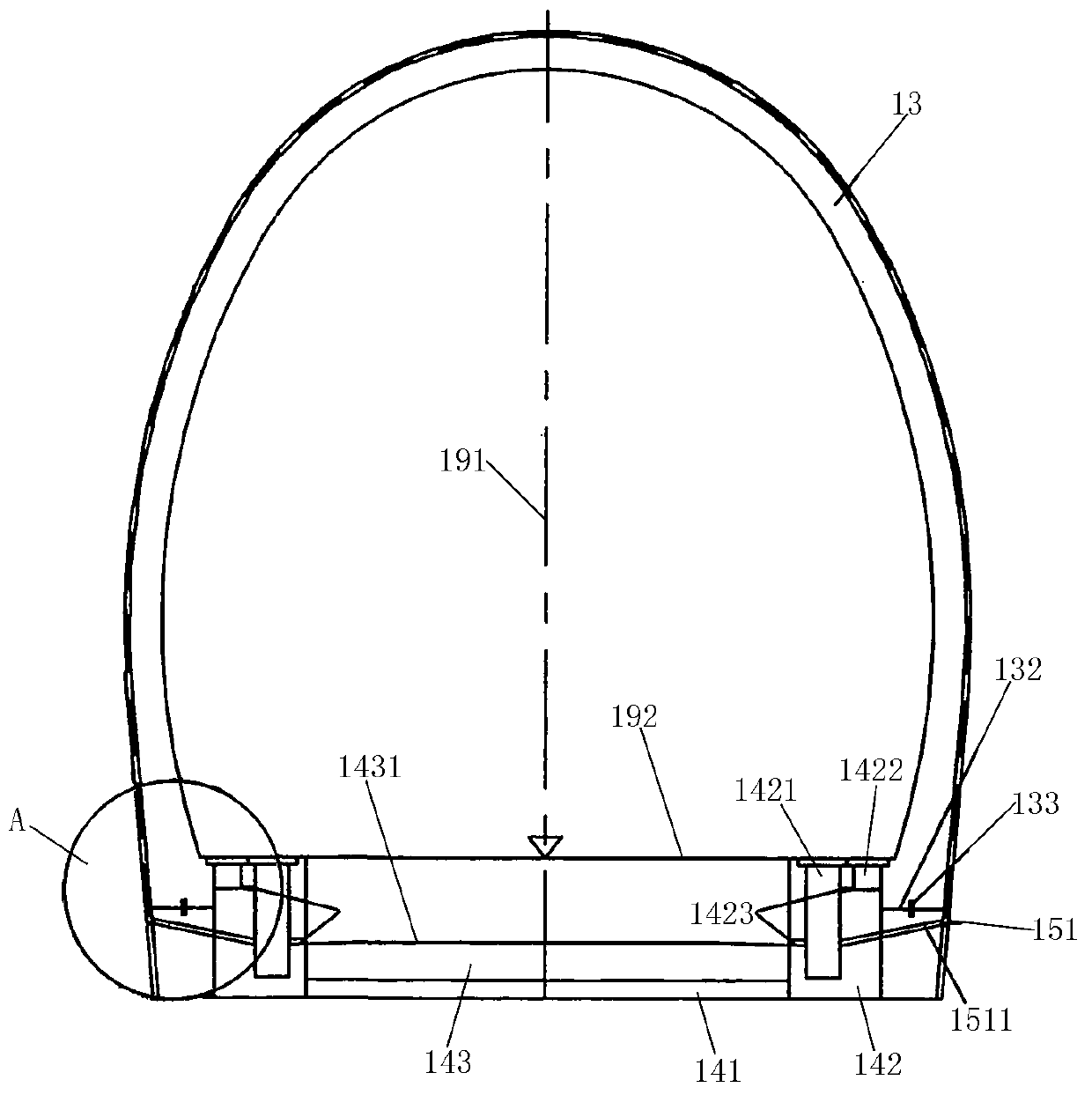

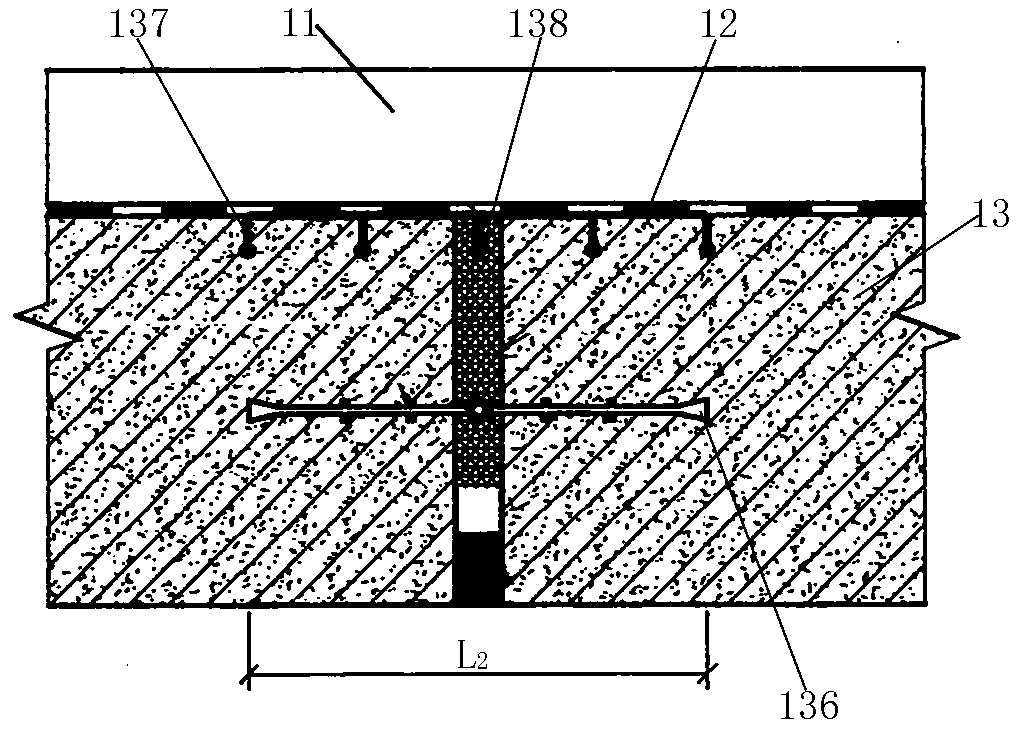

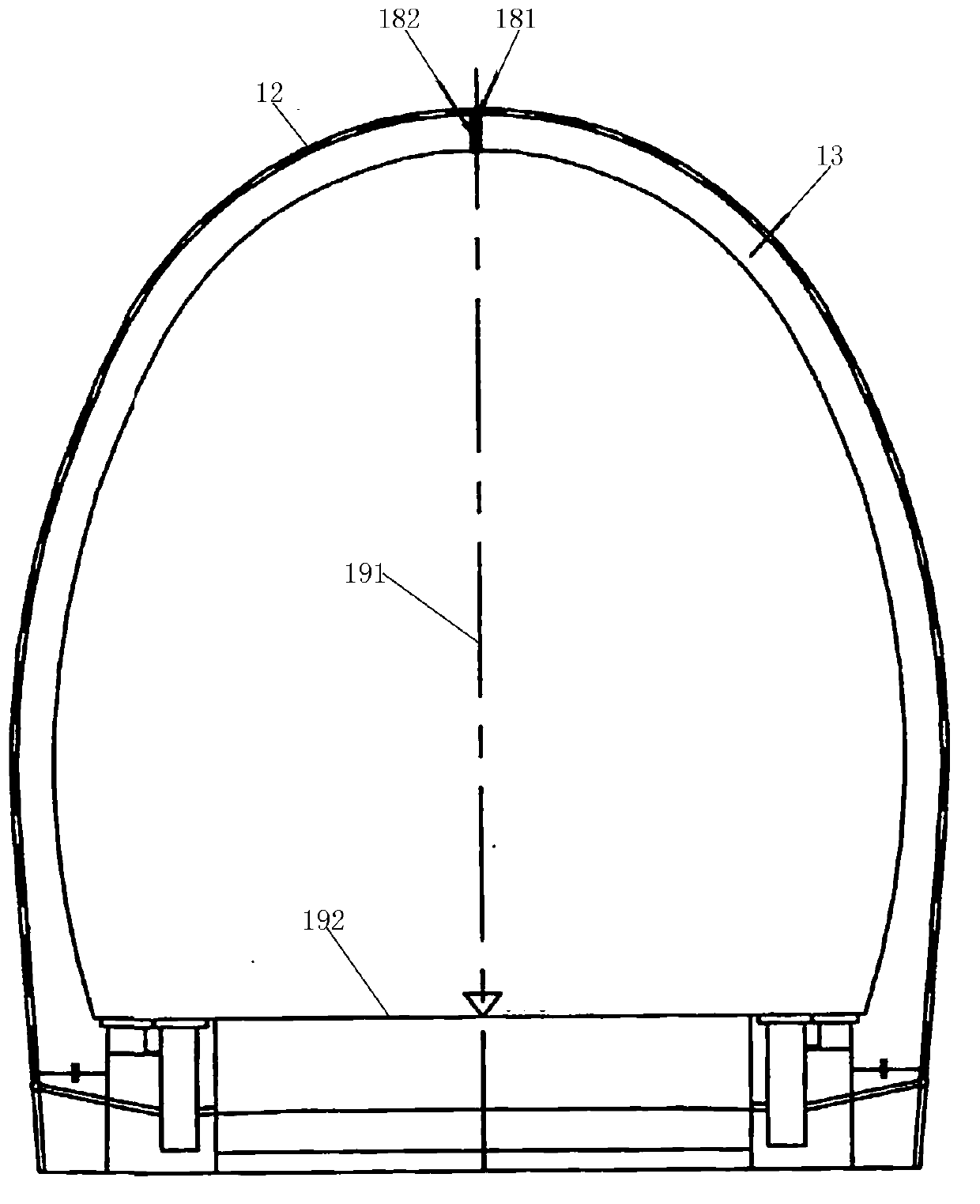

[0049] A tunnel waterproof drainage structure, please refer to Figure 1 to Figure 12 .

[0050] Such as figure 1 and figure 2 As shown, the tunnel waterproof and drainage structure provided in this embodiment is used for the first and second grade surrounding rock cave sections. The tunnel waterproof and drainage structure includes an initial support layer 11, a waterproof coiled material layer 12, The secondary molded lining layer 13, the initial support layer 11 is the concrete slurry sprayed on the wall of the excavated tunnel or the anchor rod is first driven into the wall of the excavated tunnel and then the concrete slurry is sprayed, the initial support layer 11 and the waterproof membrane A layer of geotextile 121 is laid between the layers 12. The geotextile 121 has good water permeability and can protect and prevent the waterproof membrane layer 12 from being pierced. Concrete is poured after the dolly formwork. The arch wall of the tunnel is composed of the pr...

Embodiment 2

[0067] A tunnel waterproof drainage structure, please refer to Figure 13 to Figure 15 .

[0068] Such as Figure 13 As shown, the tunnel waterproof and drainage structure provided in this embodiment is used for III, IV, and V surrounding rock cave sections. The tunnel arch wall composed of the coiled material layer 22 and the secondary molded lining layer 23 is also provided with a tunnel invert at the bottom of the excavated tunnel. The tunnel invert includes the bottom primary support layer 241 and the bottom secondary molded lining layer 242 And filling layer 243, to enhance the supporting capacity of the entire tunnel.

[0069] Such as Figure 14 As shown, in the circular construction joint 231 section of the inverted arch of the tunnel, a mid-buried rubber waterstop 2421 is provided in the middle of the secondary molded lining layer 242 at the bottom, and a rubber waterstop 2421 is buried on the lower surface of the secondary molded lining layer 242 Back-adhesive rub...

Embodiment 3

[0072] A tunnel waterproof and drainage method, comprising:

[0073] (1) Construction of the main waterproof and drainage structure: the primary support layer, the waterproof membrane layer, and the secondary molded lining layer are successively installed on the wall of the excavated tunnel; A longitudinal blind pipe is buried at the bottom, and the two ends of the longitudinal blind pipe are bent inward and connected to the side ditch; a circumferential drainage board is arranged at intervals between the initial support layer and the waterproof membrane layer, and the two ends of the circumferential drainage board are connected to the corresponding vertical blind tube.

[0074] A layer of geotextile is laid on the waterproof membrane layer to prevent it from being punctured. The waterproof membrane layer constitutes the main waterproof structure of the tunnel arch wall, and the main drainage structure of the tunnel arch wall is composed of the above-mentioned circular drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com